Novel radix angelicae sinensis tobacco flavor and preparation method thereof

A technology for tobacco flavor and angelica, applied in the directions of essential oils/flavors, tobacco, application, etc., can solve the problems of tobacco flavor residue and irritation of ordinary angelica extract, and achieve the improvement of cigarette quality, tobacco flavor, and simple equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

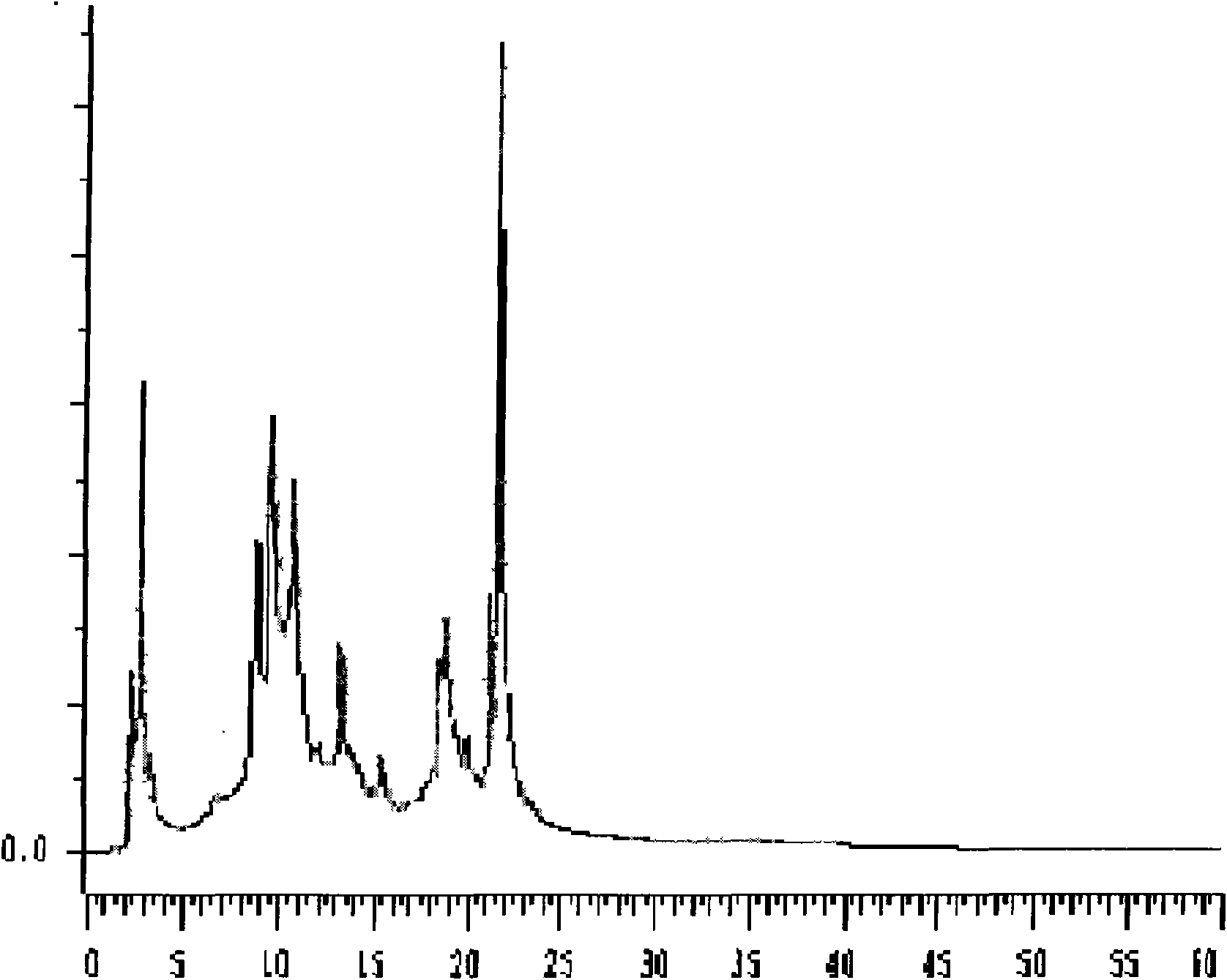

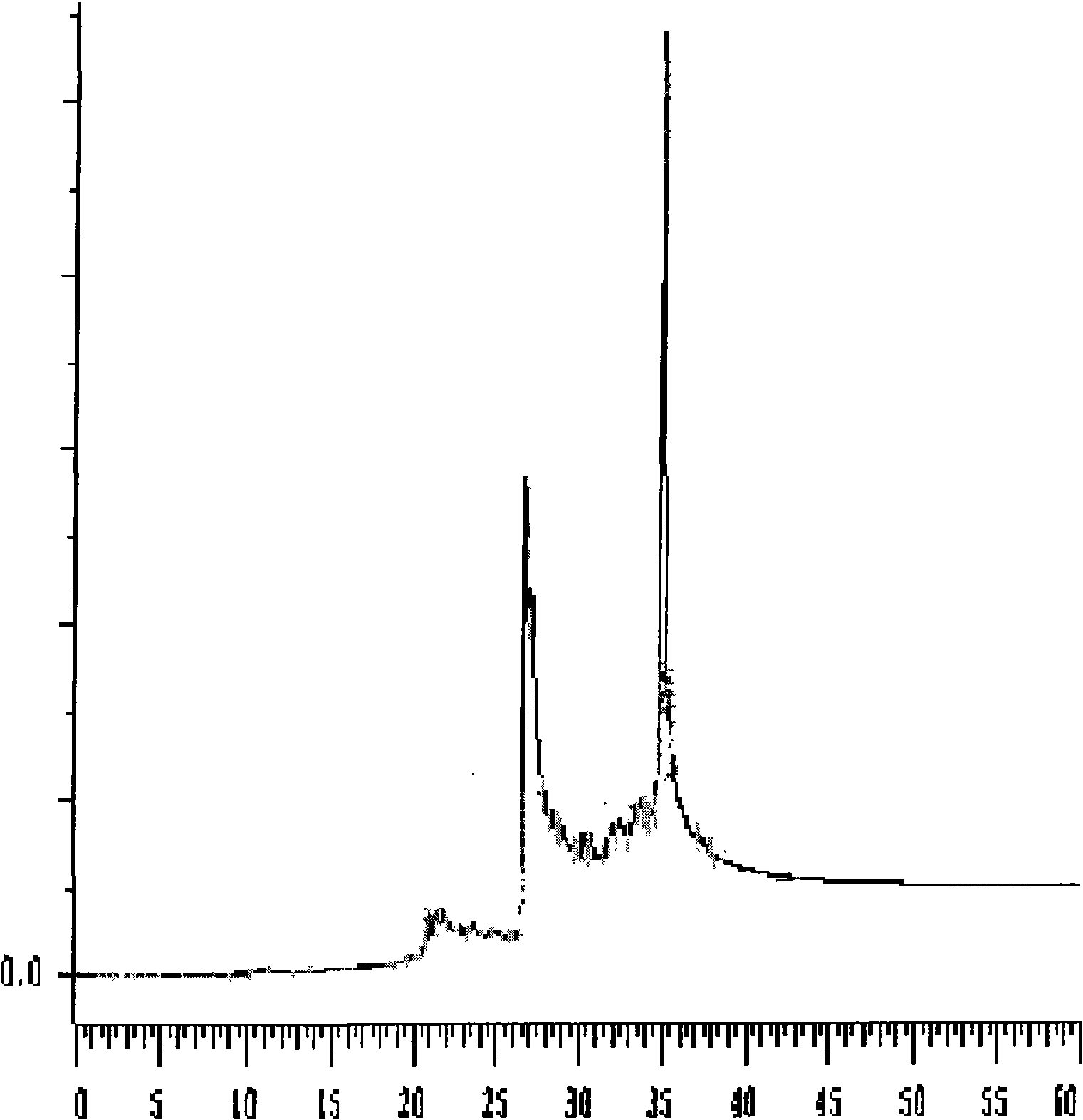

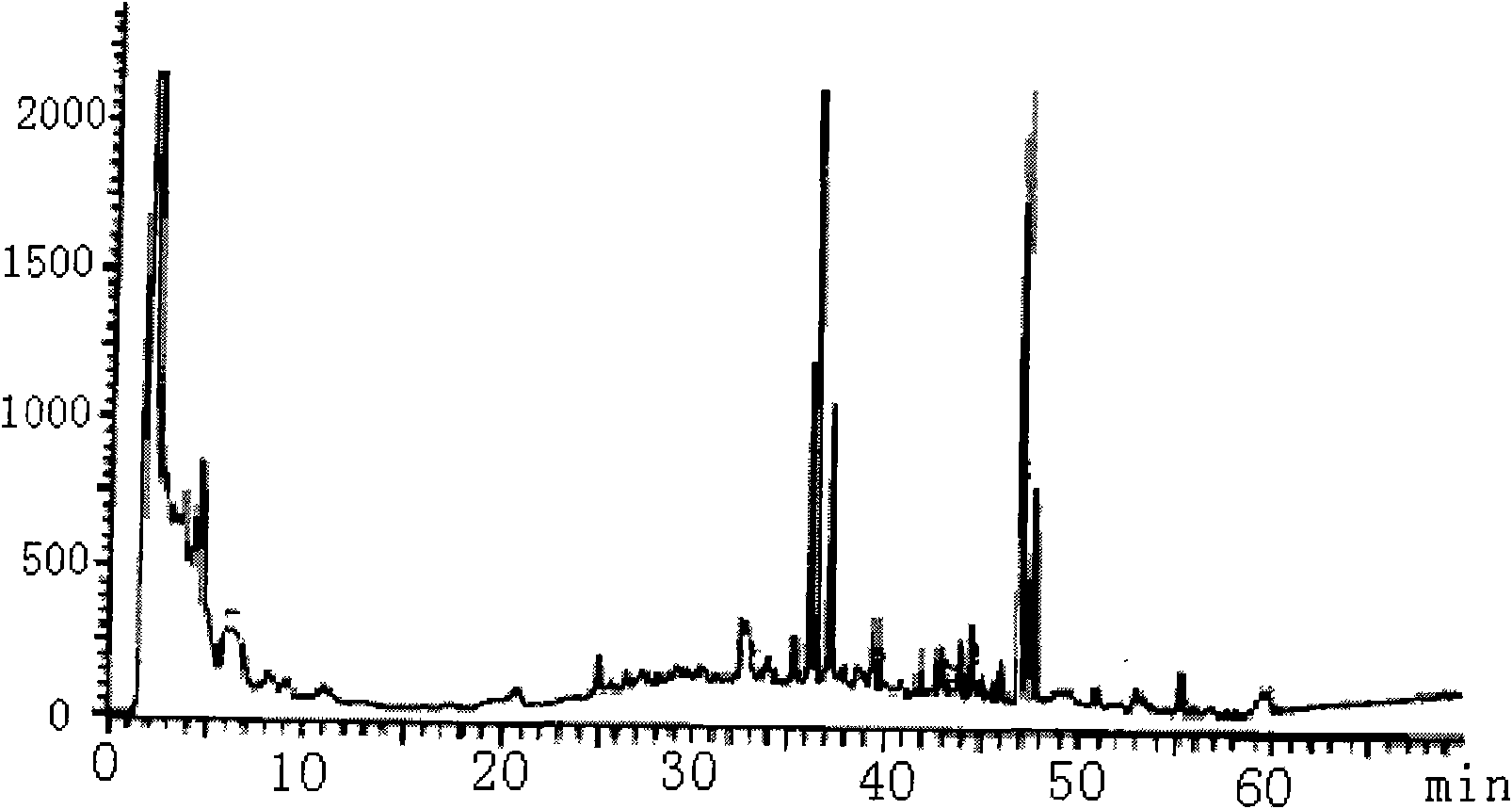

Image

Examples

Embodiment 1

[0020] Crush the angelica to 10 meshes, take a certain amount of broken angelica and put it into a glass flask, add 95% ethanol at a ratio of 1:5, soak for 2 hours, let the material fully infiltrate, reflux for 4 hours, and filter to obtain the extract. Concentrate to a density of 1.0479 to obtain the crude extract of Angelica sinensis.

[0021] Activation of macroporous resin: ① Soak three times in water, soak overnight for the third time; ② Soak twice overnight with 25-50% ethanol; ③ Soak twice overnight with 70-95% ethanol; Twice overnight; ⑤ Soak three times in water, and after soaking overnight for the third time, it will be the activated macroporous resin. Only the resin at this time can be used for the separation and purification of the crude extract.

[0022] The mass ratio of the crude extract and the macroporous adsorption resin is added to the upper end of the resin column in a ratio of 1:10. Then 70% ethanol was used to elute the liquid into a colorless state, an...

Embodiment 2

[0024] Crush the angelica to 10 mesh, take a certain amount of broken angelica and put it into a glass flask, add 50% ethanol at a ratio of 1:10, soak for 2 hours, let the material fully infiltrate, reflux for 0.5 hours, and filter to obtain the extract. Concentrate to a density of 1.0479 to obtain the crude extract of Angelica sinensis.

[0025] The mass ratio of the crude extract and the macroporous adsorption resin is added to the upper end of the resin column in a ratio of 1:10. Then 95% ethanol is used to elute the liquid into a colorless state, and the ethanol eluate is collected and concentrated to a density of 1.0479-1.2158 to obtain the flavor for tobacco of the present invention.

Embodiment 3

[0027] Crush the angelica to 10 meshes, take a certain amount of broken angelica and put it into a glass flask, add 75% ethanol at a ratio of 1:8, soak for 2 hours, let the material fully infiltrate, reflux for 2 hours, and filter to obtain the extract. Concentrate to a density of 1.0479 to obtain the crude extract of Angelica sinensis. The mass ratio of the crude extract and the macroporous adsorption resin is added to the upper end of the resin column in a ratio of 1:10. Then 70% ethanol was used to elute the liquid into a colorless state, and the ethanol eluate was collected and concentrated to a density of 1.0479-1.2158 to obtain the flavor for tobacco of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com