Anhydrous printing technique for textiles

A technology for waterless printing and textiles, applied in textiles, papermaking, dyeing and other directions, can solve the problems of large space occupation, high energy consumption, water consumption and other problems, so as to reduce the space occupied by equipment, shorten the process flow, and simplify the process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

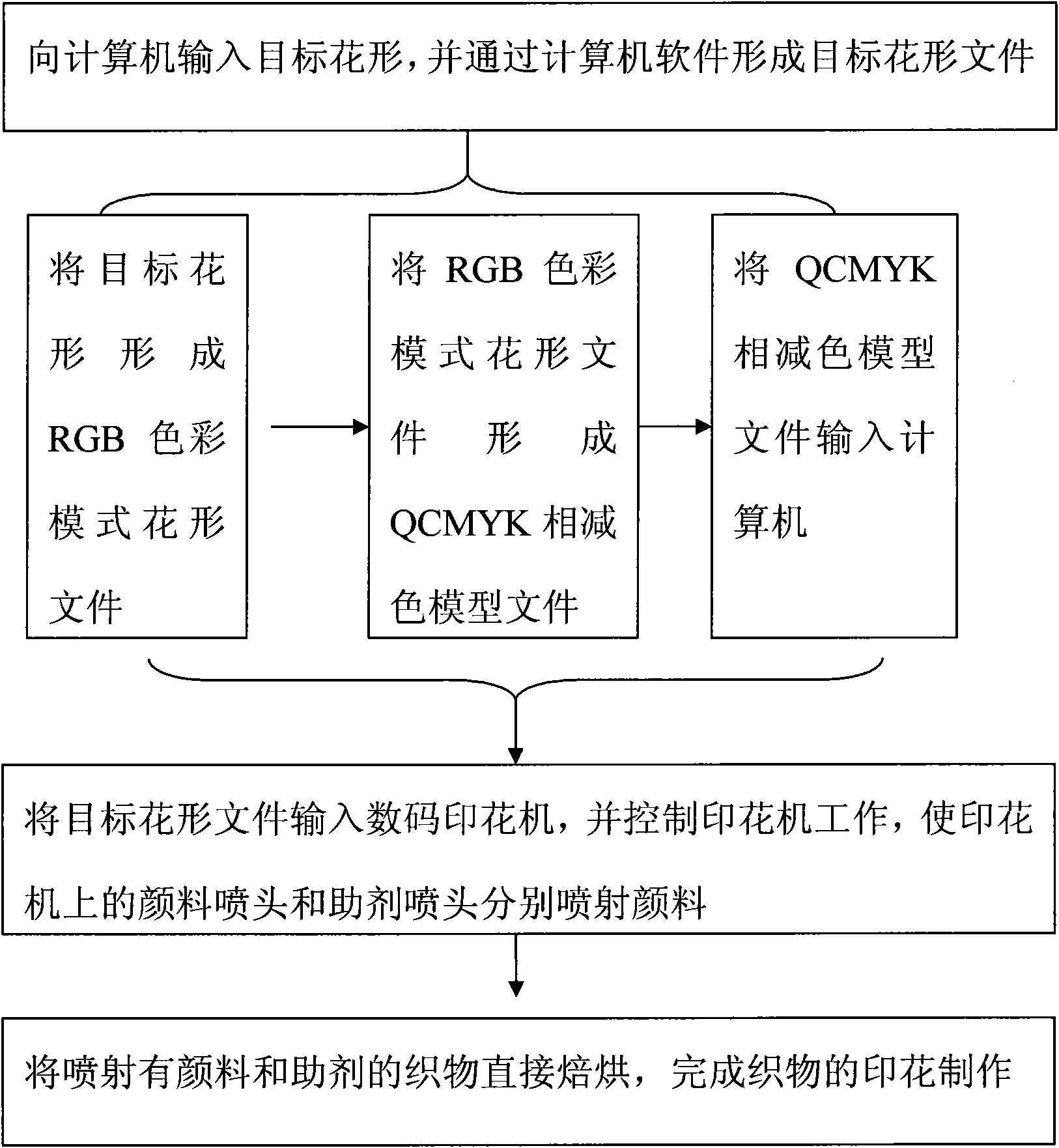

[0019] Embodiment: Textile waterless printing process, it is characterized in that its steps include: Step 1: Form the target pattern file that the digital printing machine can recognize in the computer; Step 2: The computer transmits the target pattern file to the digital printing machine, the target pattern file Control the digital printing machine so that the printed pattern consistent with the target pattern is formed on the fabric, and the pigment nozzle and the color-fixing agent nozzle on the injection device on the digital printing machine spray the pigment and the color-fixing agent respectively on the fabric; Step 3: Form a The printed fabric is sent to the baking device to fix the color of the fabric.

[0020] The specific process of forming the target pattern file recognizable by the digital printing machine in the computer described in step one is: a, inputting the target pattern into the computer to form a pattern file with RGB color mode; b, forming the pattern f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com