Portable pneumatic high/medium voltage transducer checking device

A calibration device, medium and high pressure technology, used in measuring devices, instruments, measuring fluid pressure, etc., can solve the problems of large leakage, easy to cause blockage, defects in gas pressure relief valve control, etc., to improve durability, avoid pipe The effect of road congestion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

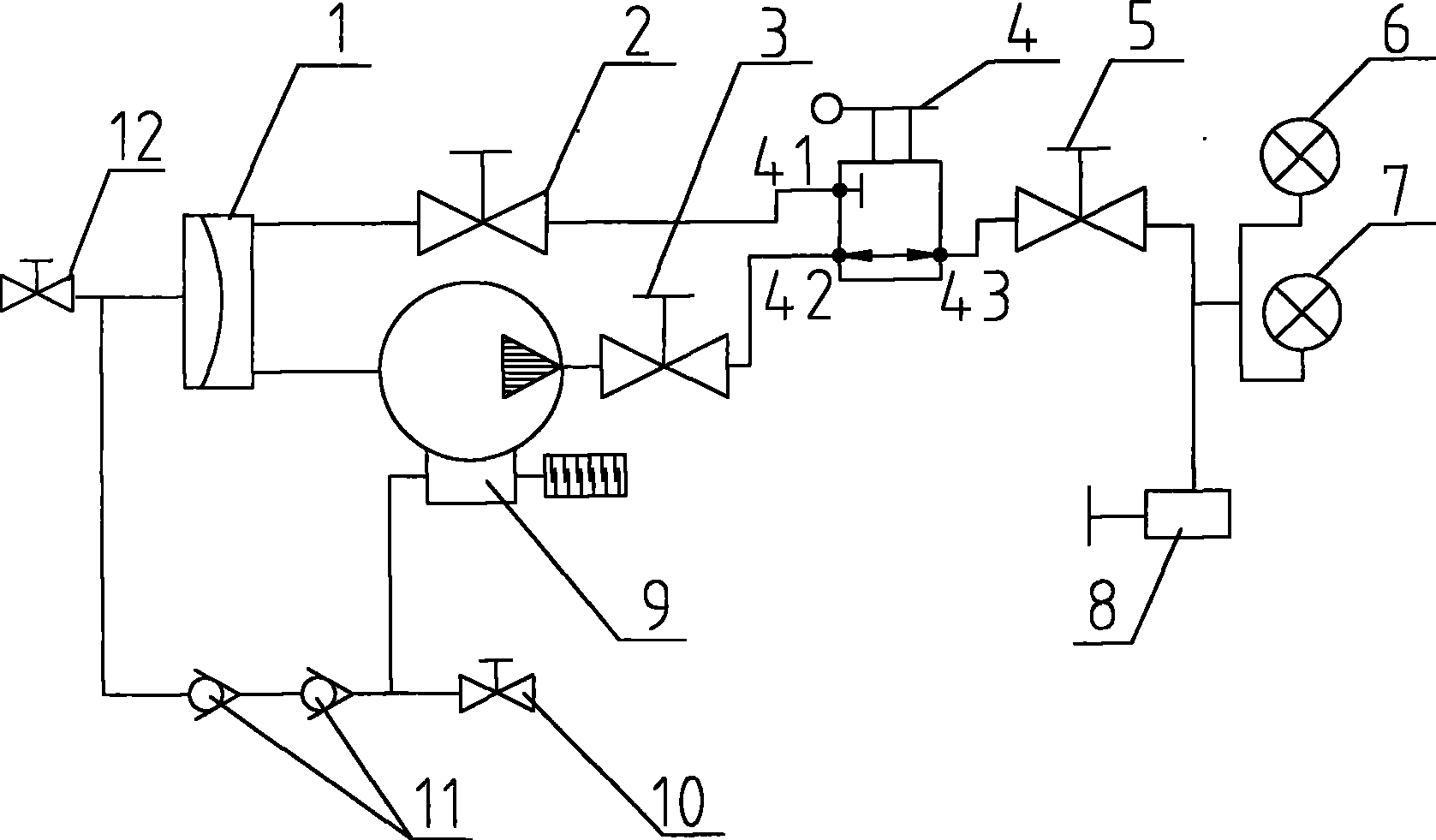

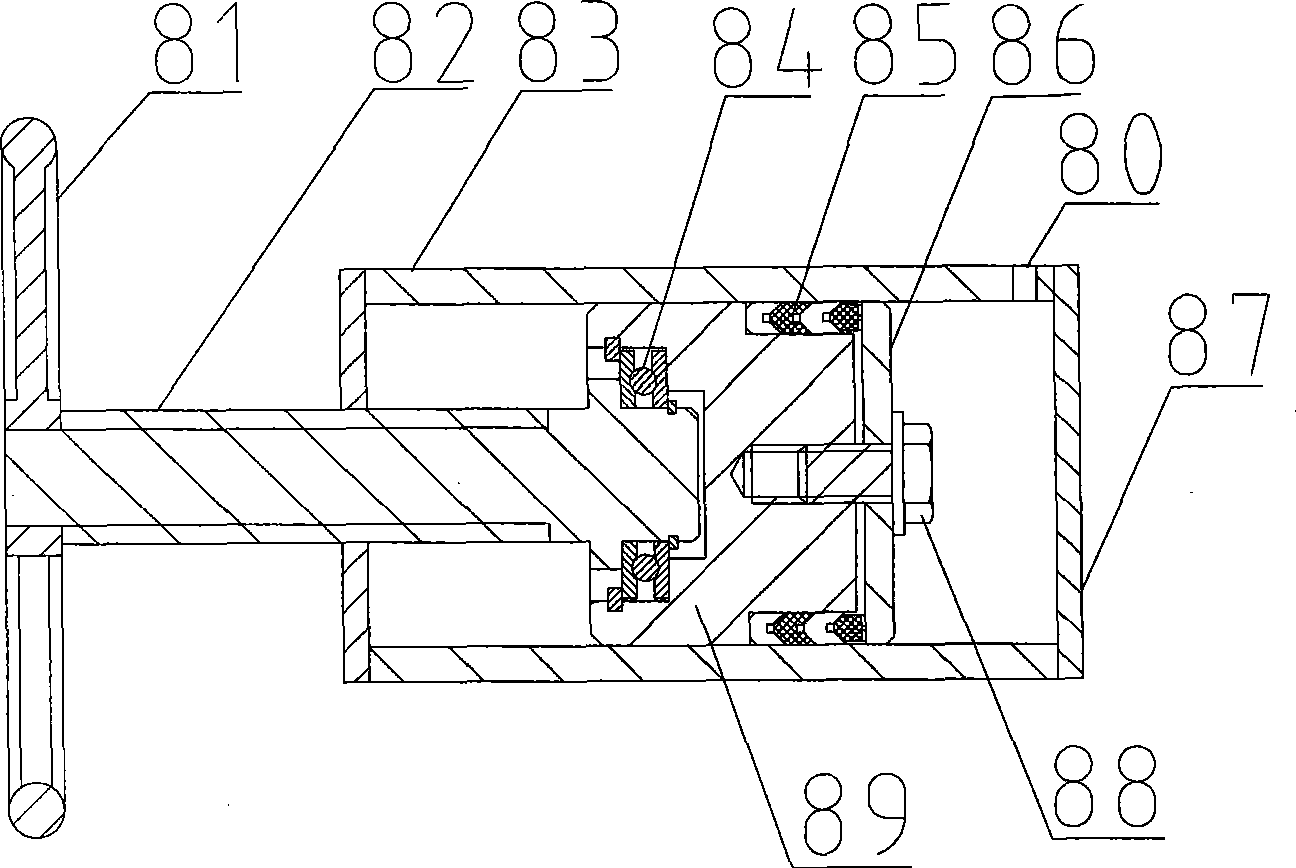

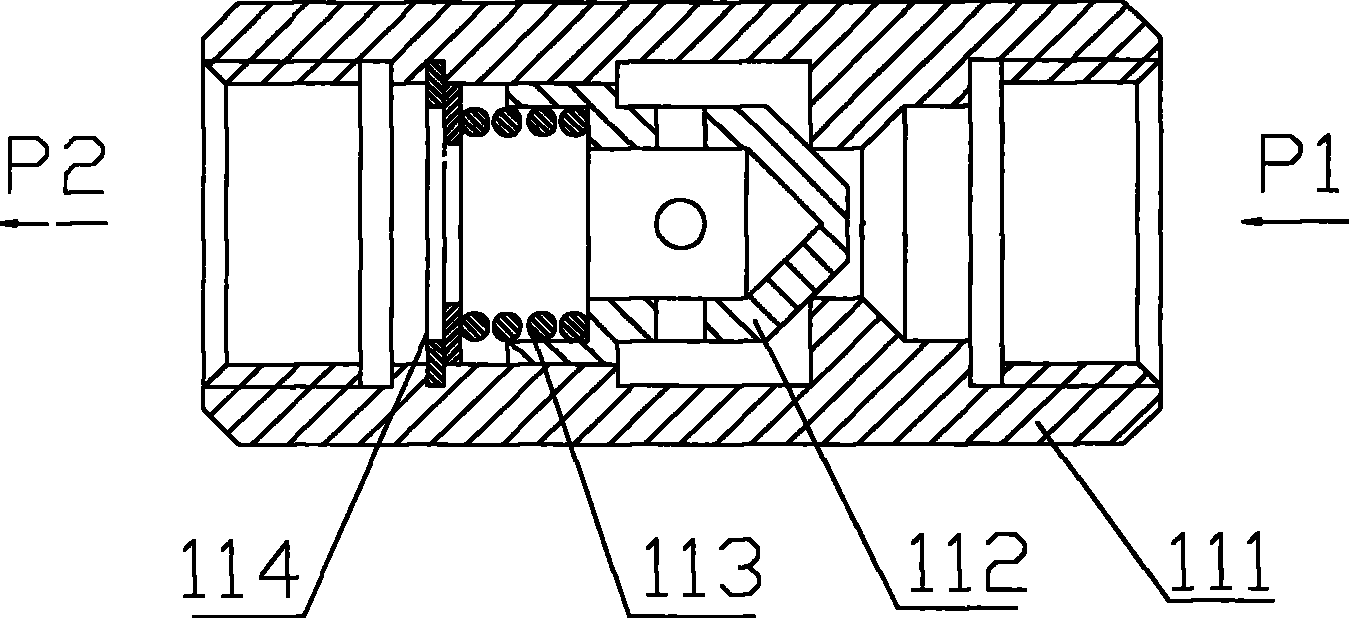

[0016] like figure 1 As shown, the portable pneumatic medium and high pressure transmitter calibration device of the present invention includes a diaphragm box 1, a release control valve 2, a pressure reducing regulating valve 3, a reversing valve 4, a stop valve 5, a fine-tuning valve 8, an intake valve 10, Air release valve 12, two one-way valves 11, pneumatic booster pump 9, standard meter 6 and tested meter 7, the reversing valve 4 is provided with a first connection end 41, a second connection end 42 and a third connection end end 43, one end of the inlet valve 10 is connected to the gas input end of the diaphragm box 1 after the two check valves 11 are connected in series, and one end of the deflation valve 12 is connected to the gas input end of the diaphragm case 1 One end of the air intake valve 10 is also connected to the gas input end of the pneumatic booster pump 9, the oil pipe port of the diaphragm box 1 is connected to the oil pipe port of the pneumatic booster ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com