Hollow fiber membrane dehumidifier

A silk membrane and hollow technology, which is applied in the field of hollow fiber membrane dehumidification devices, can solve problems such as difficult configuration, uneven flow of waste gas or purified gas, and increased area, so as to improve assembly and operability, shorten assembly time and disassembly the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

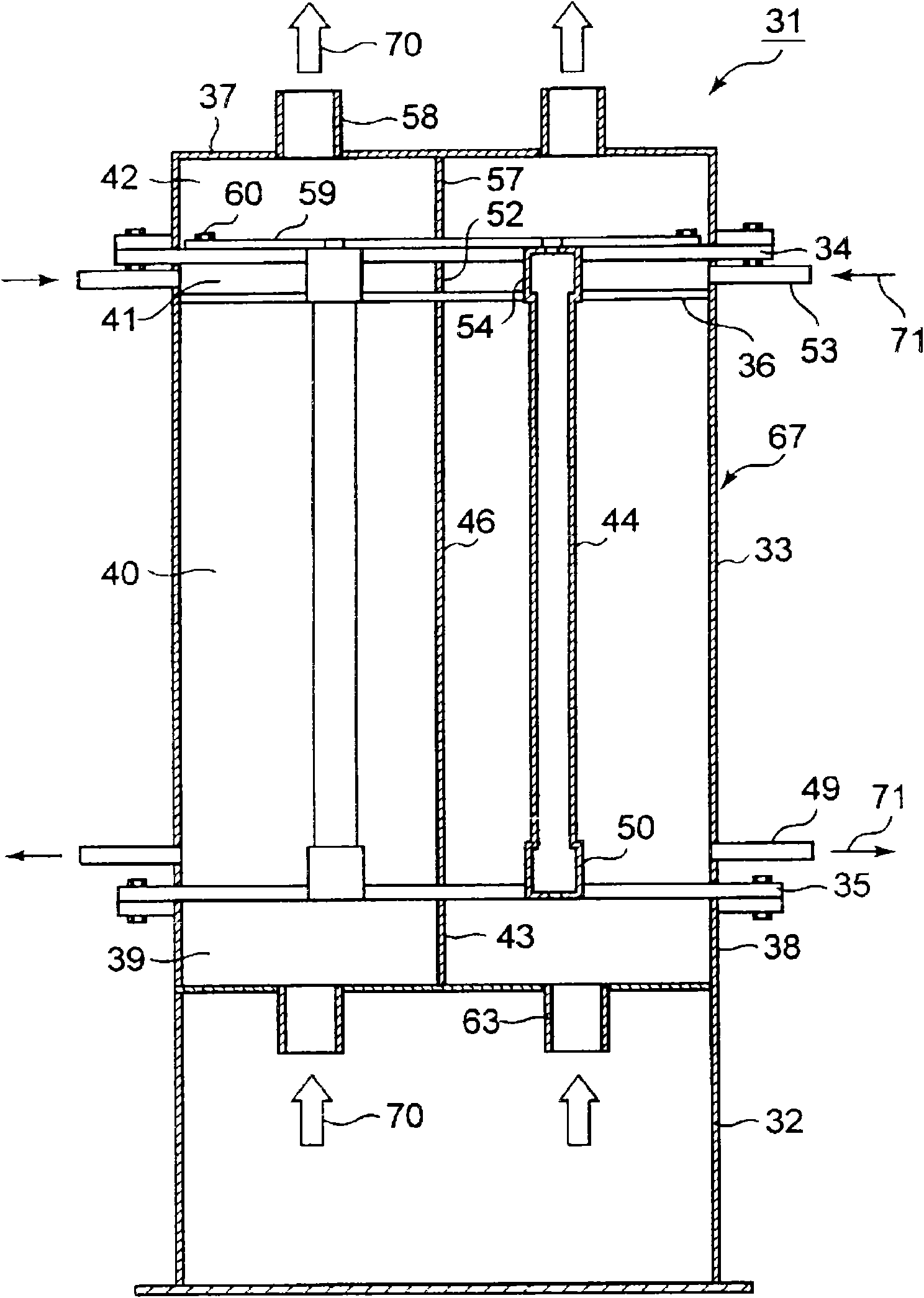

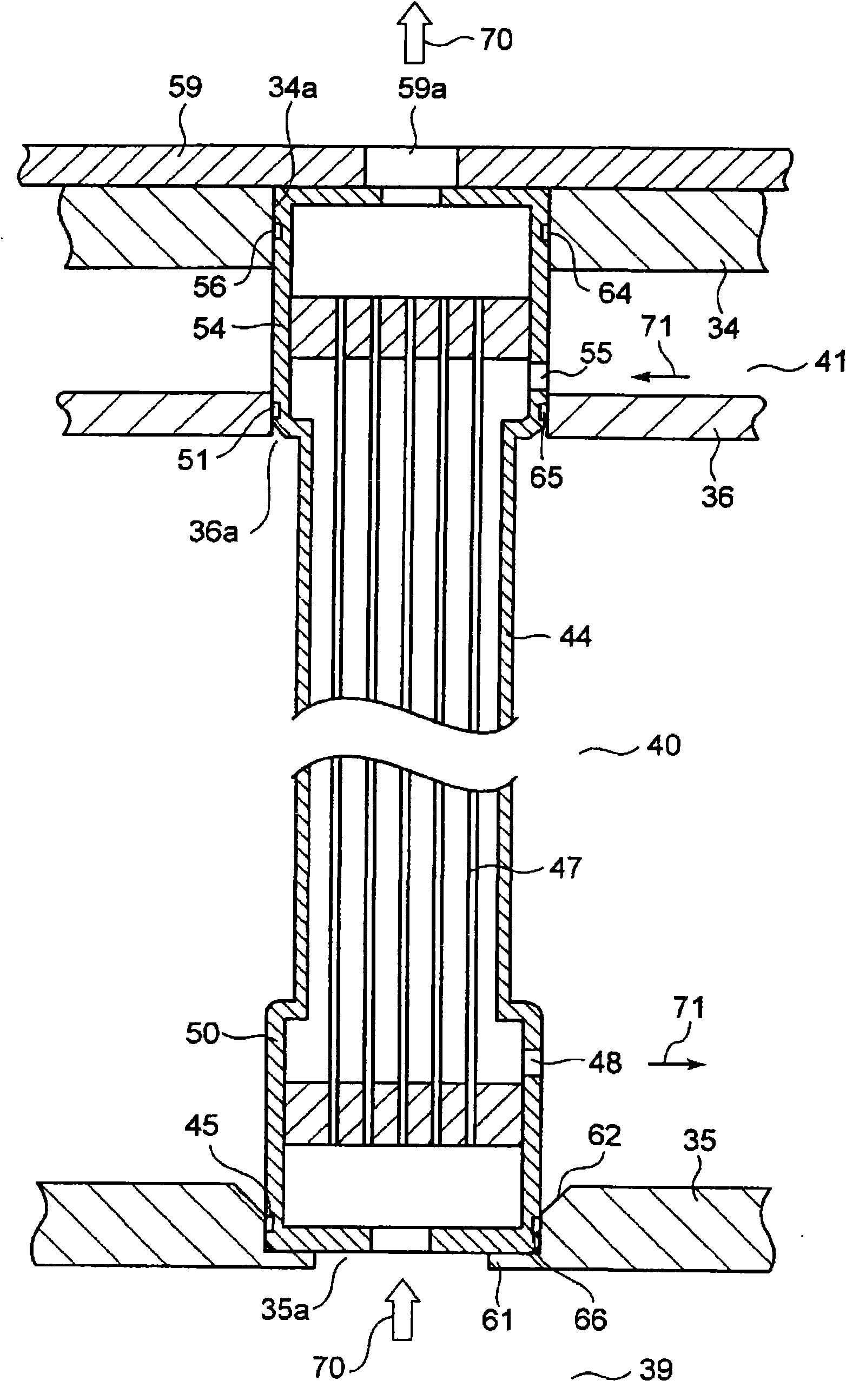

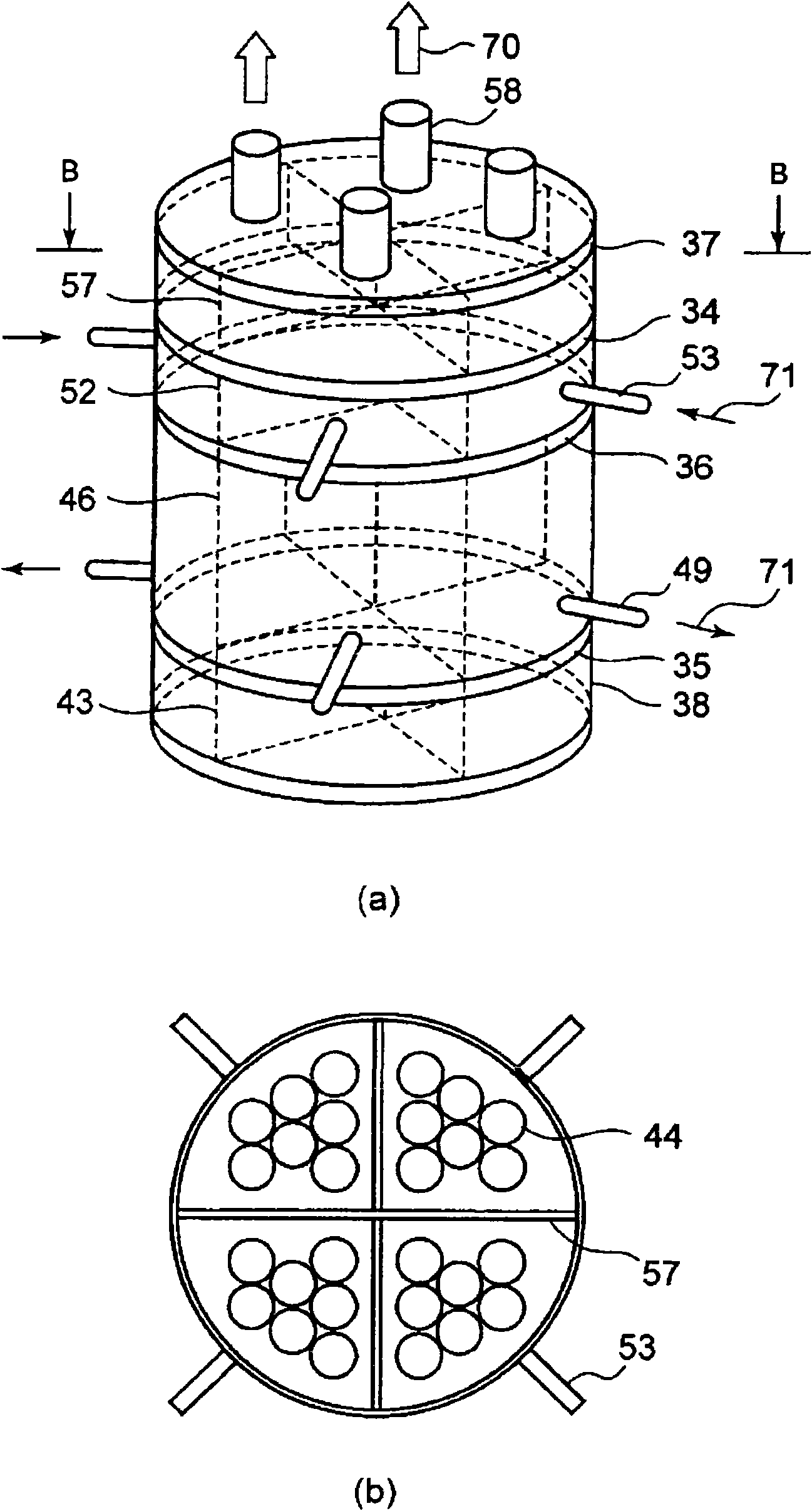

[0036] Hereinafter, embodiments of the hollow fiber membrane dehumidification device of the present invention will be described with reference to the drawings. Here, the same symbols are attached to the same or similar parts, and repeated explanations are omitted.

[0037] figure 1 It is a schematic longitudinal sectional view showing the structure of the hollow fiber membrane dehumidifier according to the first embodiment of the present invention, figure 2 yes means figure 1 A partial enlarged view of the installation structure of the hollow fiber membrane module shown, image 3 yes means figure 1 (a) is a perspective view of the hollow fiber membrane dehumidifier, (b) is a cross-sectional view cut along the B-B direction of (a).

[0038] First, as an example, using figure 1 The basic configuration of the hollow fiber membrane dehumidification device 31 suitable for dehumidification of exhaust gas from a nuclear power plant will be described.

[0039] Such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com