BOPP antibacterial food pearlized film and manufacturing method thereof

A manufacturing method and technology of pearlescent film, applied in the direction of flexible covering, coating, packaging, etc., to achieve the effect of reducing water permeability and air permeability, increasing barrier properties, and reducing the chance of intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

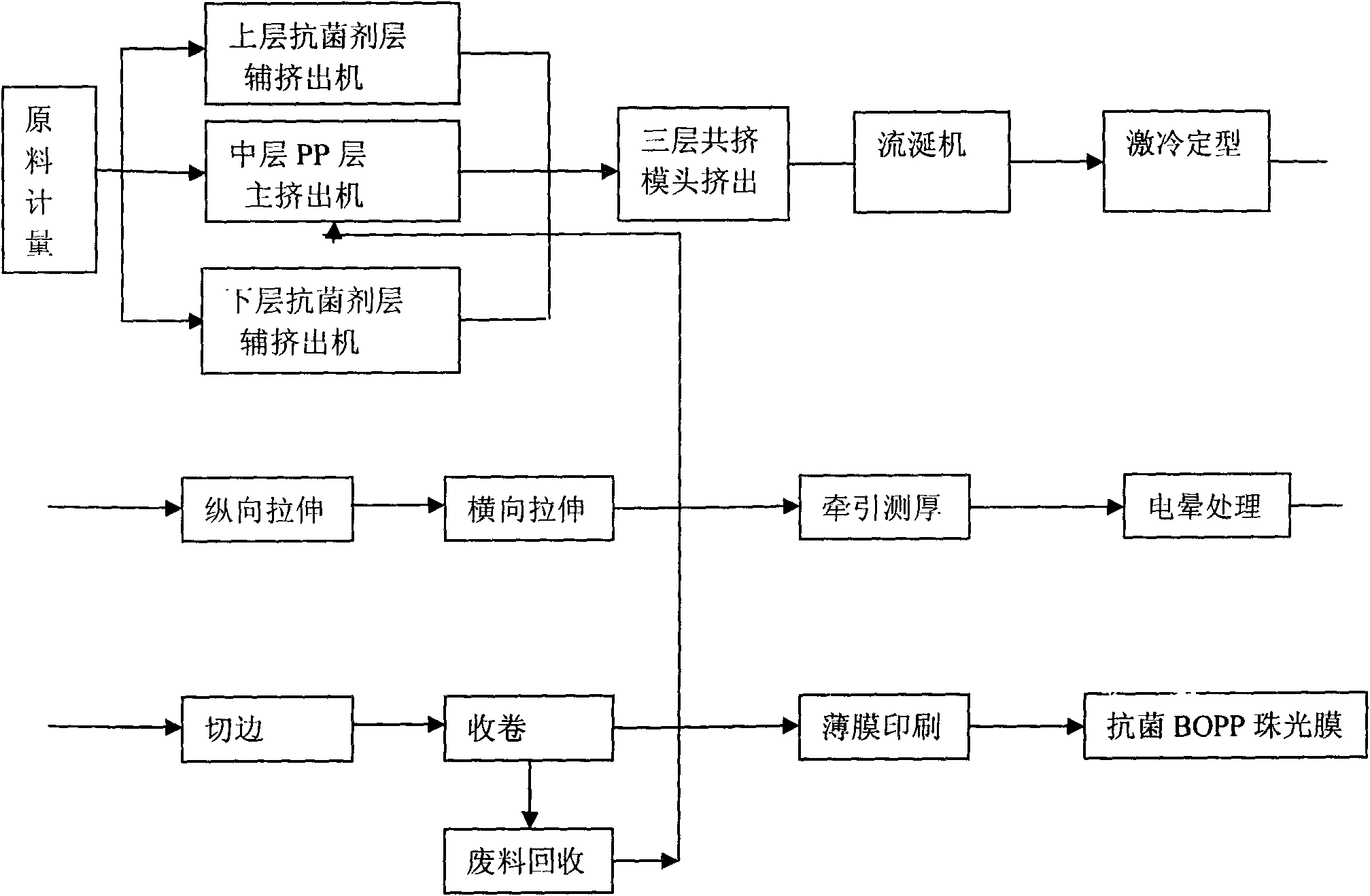

Method used

Image

Examples

Embodiment 1

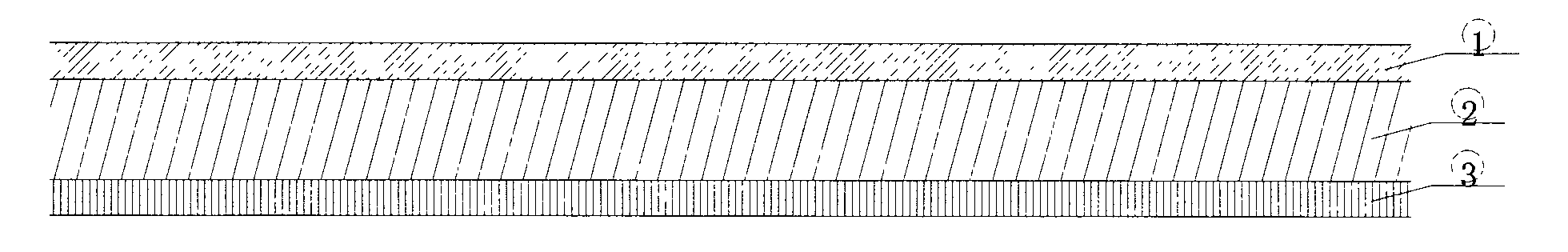

[0029] refer to figure 1 , a BOPP antibacterial food pearlescent film, the BOPP antibacterial food pearlescent film includes an upper antibacterial agent layer 1, a lower antibacterial agent layer 3 and an intermediate PP layer 2 between the upper antibacterial agent layer and the lower antibacterial agent layer; The middle PP layer 2 is covered on the lower antibacterial agent layer 3, and the upper antibacterial agent layer 1 is covered on the middle PP layer 2;

[0030] In the BOPP antibacterial food pearlescent film, the mass content of the upper antibacterial agent layer 1 and the lower antibacterial agent layer 3 is independently 3%, and the middle PP layer 2 is 94%;

[0031] Both the upper antibacterial agent layer and the lower antibacterial agent layer include PP material, nano calcium carbonate and antibacterial agent, and the mass percentages of the three components in the total mass are: 66% of PP material, 26% of nano calcium carbonate, and 8% of antibacterial ag...

Embodiment 2

[0037] refer to figure 1 , in the present embodiment, in the BOPP antibacterial food pearlescent film, the mass content of the upper antibacterial agent layer and the lower antibacterial agent layer are independently 4%, and the middle PP layer is 92%;

[0038] Both the upper antibacterial agent layer and the lower antibacterial agent layer include PP material, nano calcium carbonate and antibacterial agent, and the mass percentages of the three components in the total mass are: 70% of PP material, 23% of nano calcium carbonate, and 7% of antibacterial agent %;

[0039] The middle PP layer includes PP material, pearlescent masterbatch and nano-calcium carbonate, and the mass percentages of the three components in the total mass are: PP material 63%, pearlescent masterbatch 12%, and nano-calcium carbonate 25%.

[0040] Other structures and working processes of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0042] refer to figure 1 , in the present embodiment, in the BOPP antibacterial food pearlescent film, the mass content of the upper antibacterial agent layer and the lower antibacterial agent layer are independently 4.5%, and the middle PP layer is 91%;

[0043] Both the upper antibacterial agent layer and the lower antibacterial agent layer include PP material, nano calcium carbonate and antibacterial agent, and the mass percentages of the three components in the total mass are: PP material 72%, nano calcium carbonate 22%, antibacterial agent 6 %;

[0044] Described middle PP layer comprises PP material, pearlescent masterbatch and nano-calcium carbonate, and the mass percent that three components account for total mass is: PP material 65%, pearlescent masterbatch 10%, nano-calcium carbonate 25%.

[0045] Other structures and working processes of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com