Method for controlling torque of heavy-duty crane at zero speed

A technology of torque control and hoisting, which is applied in the direction of clockwork mechanism and hoisting device, etc. It can solve the problems of overloading of the driving system, affecting the service life of the machine, and the impact of the motor braking system, so as to improve reliability and prolong service life. , to ensure the effect of equipment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

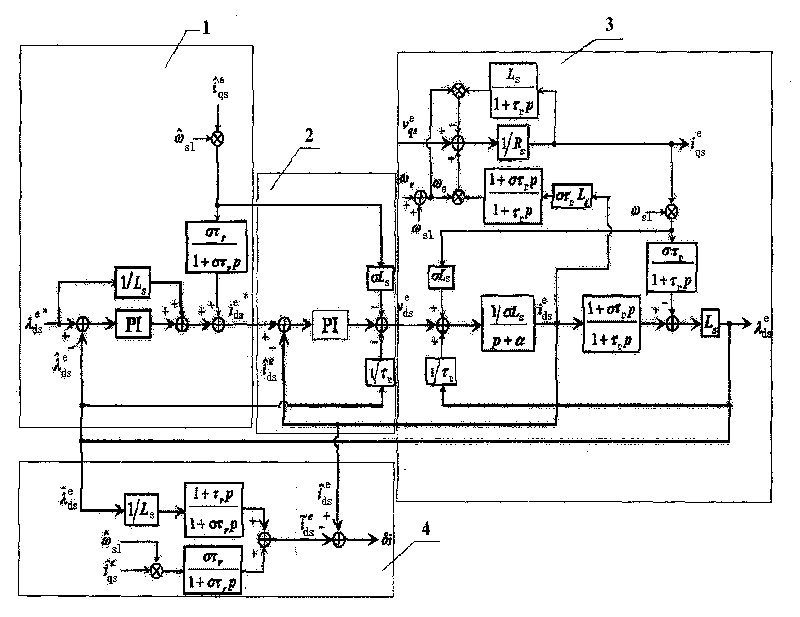

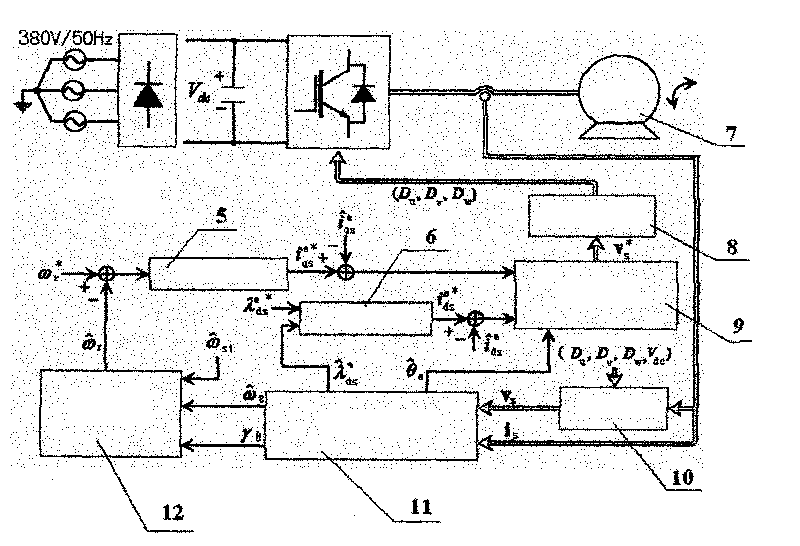

[0030] refer to figure 1 As shown, it is a schematic diagram of a zero-cross calculation mathematical model of the zero-cross torque control method of the present invention, including a magnetic flux adjustment unit 1 , a current control unit 2 , a drive calculation unit 3 and an auxiliary current estimation unit 4 .

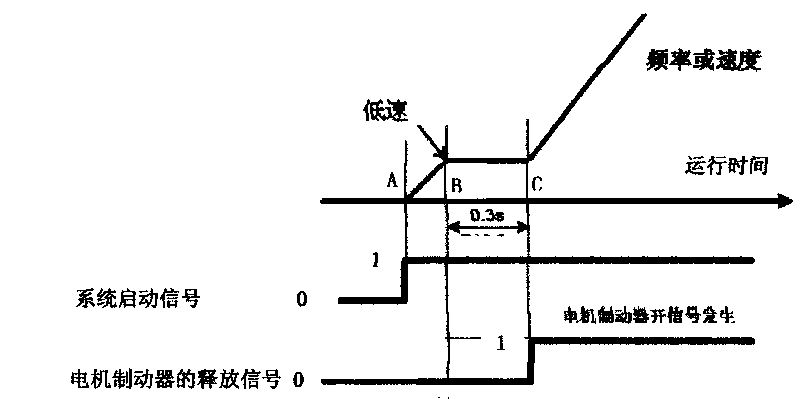

[0031] Since various parameter characteristics of the motor 7 change with changes in temperature and rotational speed, it is very important and critical for the system to quickly and accurately identify, estimate and specify the parameters of the motor 7 . If the state of the motor can be quickly identified when the motor 7 is forward and reverse zero crossing, and the relevant parameters can be estimated and given in time, it will be a good solution to the poor driving characteristics of the drive system when the motor 7 crosses zero, which is also a solution The key point of the strategy of motor 7 heavy load zero crossing without slipping the hook lies. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com