Electrospinning device for preparing nano fabrics massively

An electrospinning and nanofiber technology, which is applied in fiber processing, nonwovens, textiles and papermaking, etc., can solve the problems of affecting the strength of fabrics, insufficient improvement, uneven fiber filaments, etc., to increase spinning efficiency, spinning Improved wire efficiency and uniform thickness structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

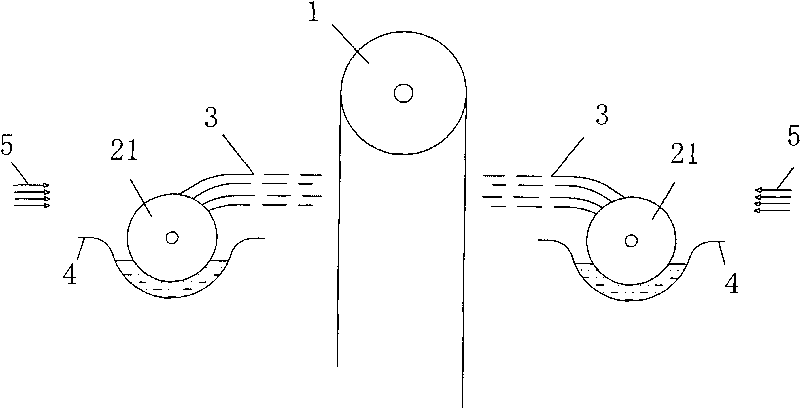

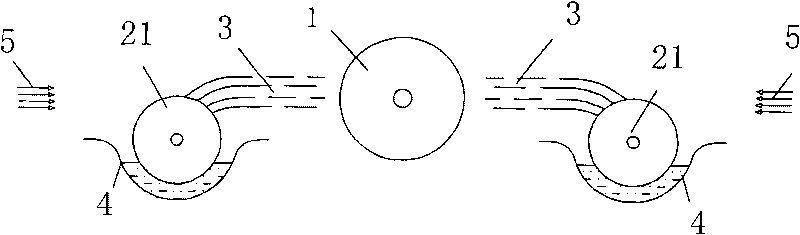

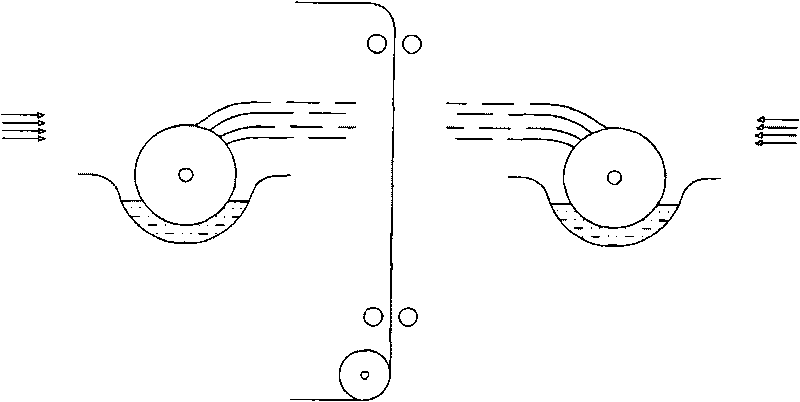

[0031] Such as figure 1 Shown, a kind of electrospinning device of preparing nanofiber fabric in a large amount, this device comprises frame, collecting device 1 and at least one group of jet generation device, said group of jet generation device is made up of two spinneret devices 2, The spinneret 2 is a rotatable cylinder 21, which is soaked in the trough 4 filled with the spinning solution 3; the two spinnerets 21 have opposite charges and are arranged oppositely. It is made of insulating material and located in the electric field formed between two spinning devices 21; the collecting device 1 is a structure of a winding drum 11.

[0032] The spinning device 21 is a rotatable drum 211 with a spiral convex structure on the surface. Such as Figure 4 As shown, the vertical height of the helicoid of the helical convex structure from the surface of the cylinder is 1 mm. The distance between the two spinnerets and the receiving surface of the collector is 15 cm respectively. ...

Embodiment 2

[0038] The collecting device is a drum device; the spinning device 21 is a rotatable drum 211, the surface of which is an annular raised structure, such as Figure 5 Shown, other structures are with embodiment 1. The distance between the two spinning devices and the receiving surface of the collecting device is 5 cm respectively. The voltage ranges of the two spinning devices are ±50kV respectively. Each spinneret rotates at a speed of 6 r / min.

[0039] The appropriate amount of average molecular weight of 2.5 × 10 4 The polyethylene terephthalate (PET) is heated to about 240°C, stirred evenly, the spinning device is immersed in the melt, and spinning is started to obtain a wide-width nanofiber non-woven fabric. The throughput is more than 3.5 g / min, and the fiber diameter is 100-1000nm.

Embodiment 3

[0041] The collection device is a conveyor belt device; the spinneret 21 is a rotatable drum 211 with a perforated surface and a hole diameter of 1mm; the distance between the two spinnerets and the receiving surface of the collector is 25cm. The voltage ranges of the two spinning devices are ±5kV respectively. Each spinneret rotates at a speed of 10 r / min.

[0042] Other structures are with embodiment 1.

[0043] Dissolve polylactic acid (PLA) with a mass fraction of 7% in a mixed solvent of dichloromethane and N,N-dimethylformamide, the volume ratio of which is 4:1, and after stirring for 5 hours with a magnetic stirrer, respectively Add an appropriate amount into the two troughs and start spinning to obtain a wide-width nanofiber non-woven fabric. The throughput is more than 3.5 g / min, and the fiber diameter is 100-1000nm.

[0044] Figure 8 Digital photograph of the nanoscale fiber nonwoven fabric prepared for this example. It can be seen that the fiber nonwoven fabri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com