Cambered surface disc spring and manufacturing method thereof

A disc spring, cambered technology, applied in the field of high-performance cambered disc springs, to improve reliability and service life, prevent major failure accidents and economic losses, and prevent rupture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

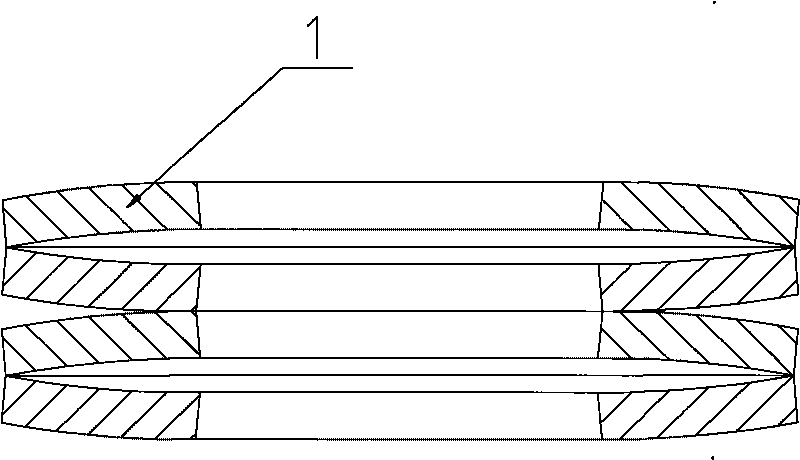

[0036] see image 3 , 4 pieces of convex arc disc springs are superimposed and combined (stiffness parallel displacement increases). The arc of the spring tends to be gentle. Since the upper and lower contact surfaces of the stacked disc springs are arc surfaces, the stress point of the disc spring will shift from the initial edge of the section to the center point of the section with the change of the compression stroke. On the contrary, when the disc spring pulls When stretching, its stress point will be displaced from the center point of the section to the edge of the section with the change of the stretching stroke; when the compression stroke exceeds 75% of the allowable regulation, the bearing capacity of the disc spring will at least double, which means The overload safety guarantee of the disc spring is greatly improved; and the reliability, safety and service life of the disc spring are improved.

Embodiment 2

[0038] see Figure 4 , two convex arc-shaped disc springs 1 superimposed combination (stiffness series displacement unchanged), when the disc spring is compressed by force, the nature of its deformation force change is that the taper of the disc spring tends to be gentle first, and then the disc spring The arc of the spring tends to be flat. Its characteristic is that the displacement constant bearing capacity is doubled.

Embodiment 3

[0040] see Figure 5 , 4 pieces of convex arc disc spring 1, 2 pieces are superimposed and then combined (stiffness and displacement increase in series), when the disc spring is compressed by force, the nature of its deformation force is first of all that the taper of the disc spring tends to be gentle , followed by the disc spring's arc becoming flatter. Its characteristic is that both displacement and bearing capacity are doubled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com