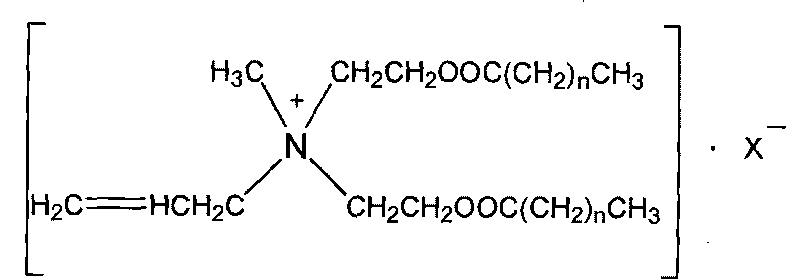

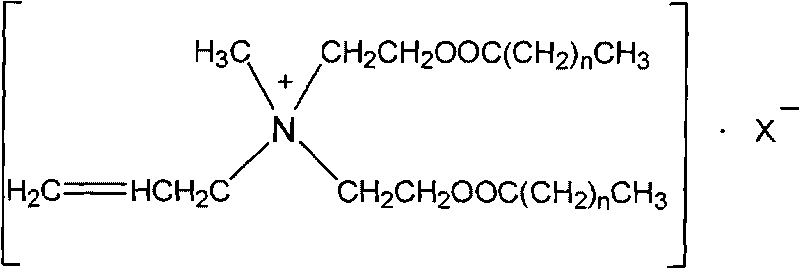

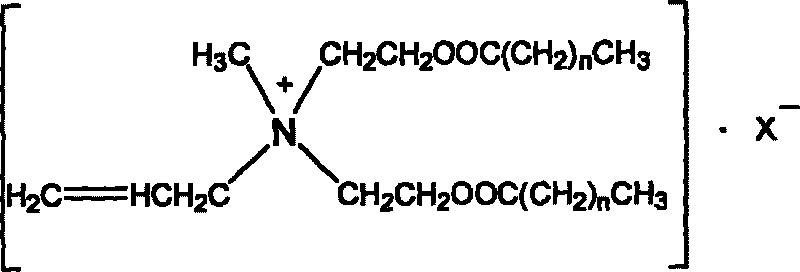

Cationic surfactant and preparation method thereof

A surfactant and cation technology, applied in the field of cationic surfactant and its preparation, achieves the effects of high yield, mild reaction conditions and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The first step: the synthesis of fatty acid methyl diethanolamine ester

[0030] In a reaction flask equipped with a rectifying column, 35.7 g (0.30 mol) of methyldiethanolamine, 132 g (0.66 mol) of n-dodecanoic acid and 0.5 g of p-toluenesulfonic acid as a catalyst were added, and the mixture was heated at 120°C to 150°C. After melting at ℃, the reaction was stirred, and the progress of the reaction was monitored by the content of separated water in the water separator. After about 8 to 10 hours, the reaction was stopped when the amount of water separated reached 95% of the theoretical water separation. The resulting reactants were dissolved in CHCl 3 , after washing with water, the organic phase was evaporated, and dried over anhydrous sodium sulfate to obtain the product, methyl diethanolamine laurate, as a pale yellow liquid with a weight of 122 g. The gas chromatography normalized detection purity was 97%, and the yield was 81%.

[0031] The second step: the synt...

Embodiment 2

[0036] According to the same operation as Example 1, only the n-dodecanoic acid 132g (0.66 mol) used therein was changed to n-dodecanoic acid 144 g (0.72 mol), and the others were unchanged to obtain the product, methyl diethanolamine laurate, pale yellow The liquid, with a weight of 126 g, has a purity of 97% as detected by gas chromatography, and a yield of 83.6%.

[0037] Based on methyldiethanolamine, the total yield was 71.69%.

Embodiment 3

[0039] According to the same operation as in Example 1, only the 3-chloropropene 3.67g (0.048mol) used in the synthesis method of the second step was changed to 3-chloropropene 4.59g (0.06mol), and the other remained unchanged to obtain the quaternary ammonium salt The product has a weight of 21.8 g, a gas chromatographic normalization detection purity of 97%, and a synthesis yield of 91.6% in the second step.

[0040] Based on methyldiethanolamine, the total yield was 74.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com