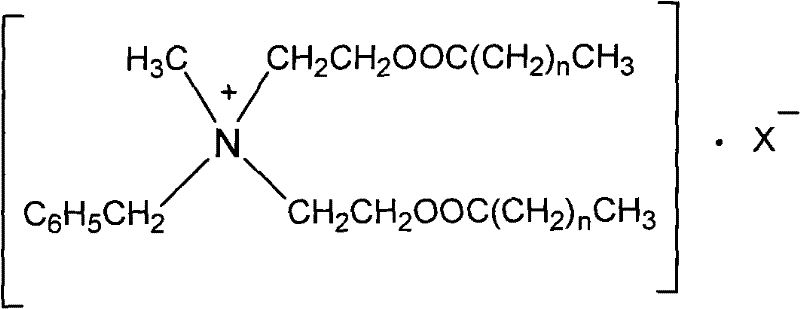

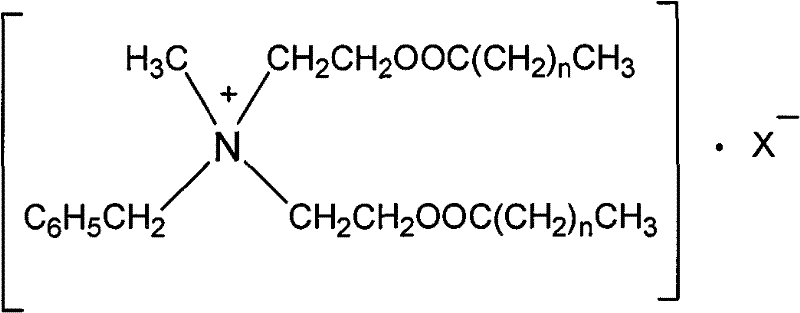

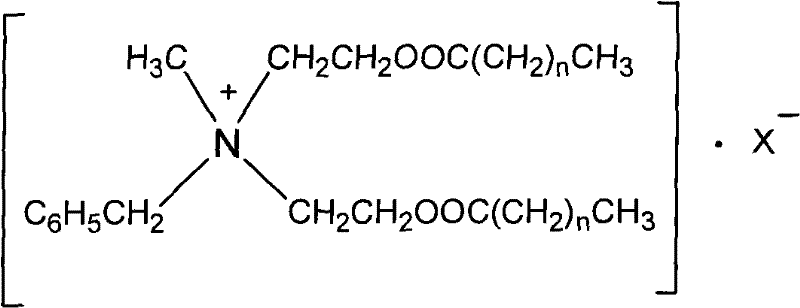

Cationic surfactant and preparation method thereof

A technology of surfactant and cation, applied in the field of cationic surfactant and its preparation, to achieve the effects of no three wastes, mild reaction conditions and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The first step: the synthesis of methyldiethanolamine laurate

[0029] In a reaction flask equipped with a rectifying column, respectively add 35.7g (0.30mol) of methyldiethanolamine, 132g (0.66mol) of n-dodecanoic acid and 0.5g of catalyst p-toluenesulfonic acid, Melt at ℃, then stir the reaction, and monitor the progress of the reaction through the water content in the water separator. After about 8-10 hours, stop the reaction when the separated water reaches 95% of the theoretical water separation. The resulting reactant was dissolved in CHCl 3 , washed with water, evaporated to remove the organic phase, and dried over anhydrous sodium sulfate to obtain the product methyldiethanolamine laurate as a light yellow liquid, with a weight of 122g. The purity detected by gas chromatography normalization was 97%, and the yield was 81%.

[0030] The second step: the synthesis of diethyl dodecanoate methyl benzyl ammonium chloride

[0031] Add 20.0 g (0.04 mol) of methyldie...

Embodiment 2

[0035] Operate in the same manner as in Example 1, only change the n-dodecanoic acid 132g (0.66mol) used therein into n-dodecanoic acid 144g (0.72mol), and the others remain unchanged, so that the product lauric acid methyldiethanolamine ester is light yellow The liquid has a weight of 126g, and the gas chromatography normalized detection purity is 97%, and the yield is 83.6%.

[0036] Based on methyldiethanolamine, the total yield of diethyl dodecanoate methyl benzyl ammonium chloride is 64.6%.

Embodiment 3

[0038] Operate in the same manner as in Example 1, only change the benzyl chloride 5.40g (0.048mol) used in the synthetic method of the second step to 6.75g (0.06mol) of benzyl chloride, and the others remain unchanged to obtain the quaternary ammonium salt product, and the weight is received 21.5g, the purity detected by bromophenol blue two-phase titration method is 94.0%, and the second-step synthesis yield is 84.4%.

[0039] Based on methyldiethanolamine, the total yield of diethyl dodecanoate methyl benzyl ammonium chloride is 68.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com