Cleaning device for liquid crystal module terminal and cleaning method thereof

A technology for cleaning equipment and liquid crystal modules, applied in the direction of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as complex equipment structures, achieve no increase in process time, save production consumables, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

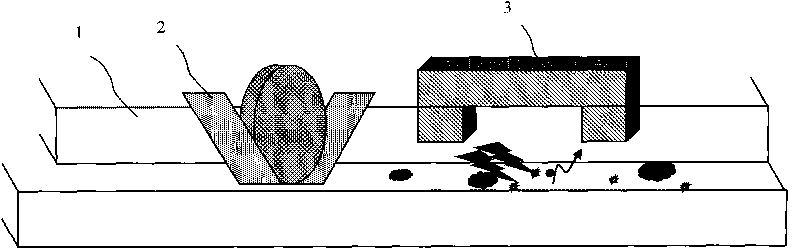

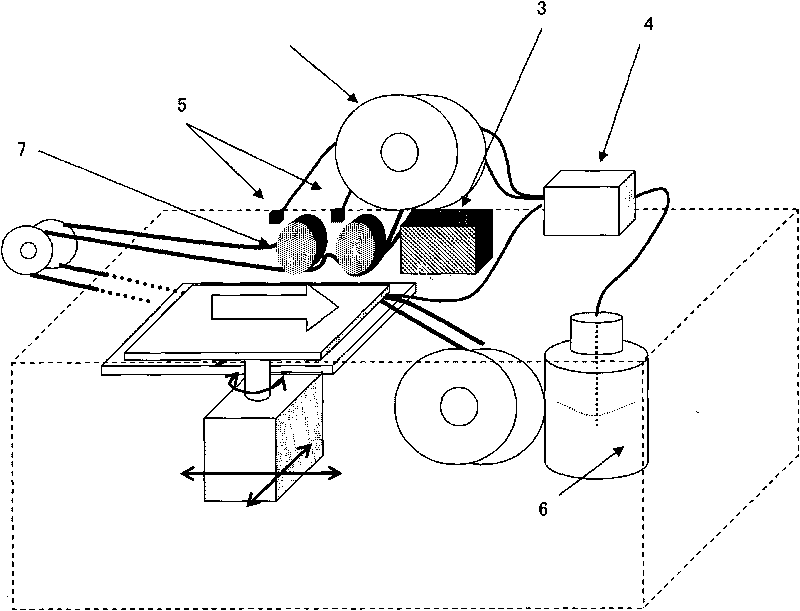

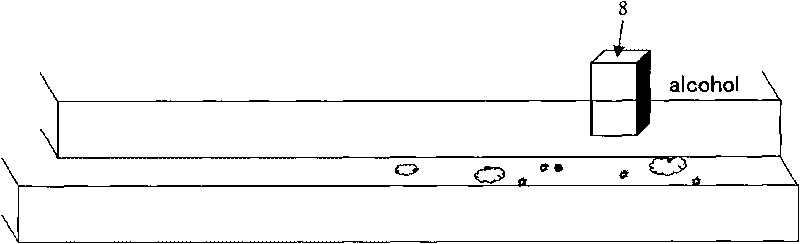

[0020] image 3 It is a schematic diagram of the ultrasonic wave plus alcohol or acetone wiping method of the present invention, Figure 4 It is a schematic diagram of ultrasonic plus alcohol or acetone wiping equipment of the present invention.

[0021] See image 3 , The ultrasonic alcohol / acetone cleaning terminal method of the present invention, ultrasonic is a relatively mature technology, using a mature ultrasonic nozzle 8, injecting alcohol or acetone to clean large particles of foreign matter and organic matter at the terminal. Please continue to see Figure 4 , the ultrasonic wave plus alcohol or acetone wiping equipment of the present invention only needs an ultrasonic nozzle 8 and an alcohol / acetone supply unit, the alcohol / acetone supply unit includes a liquid separator 4 and a liquid storage tank 6, and alcohol or acetone is plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com