Wire receiving machine for recovering steel wires

A wire take-up and steel wire technology, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, can solve the problems of high cost, high motor power, and increased cost, and achieves a small footprint and convenient operation. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

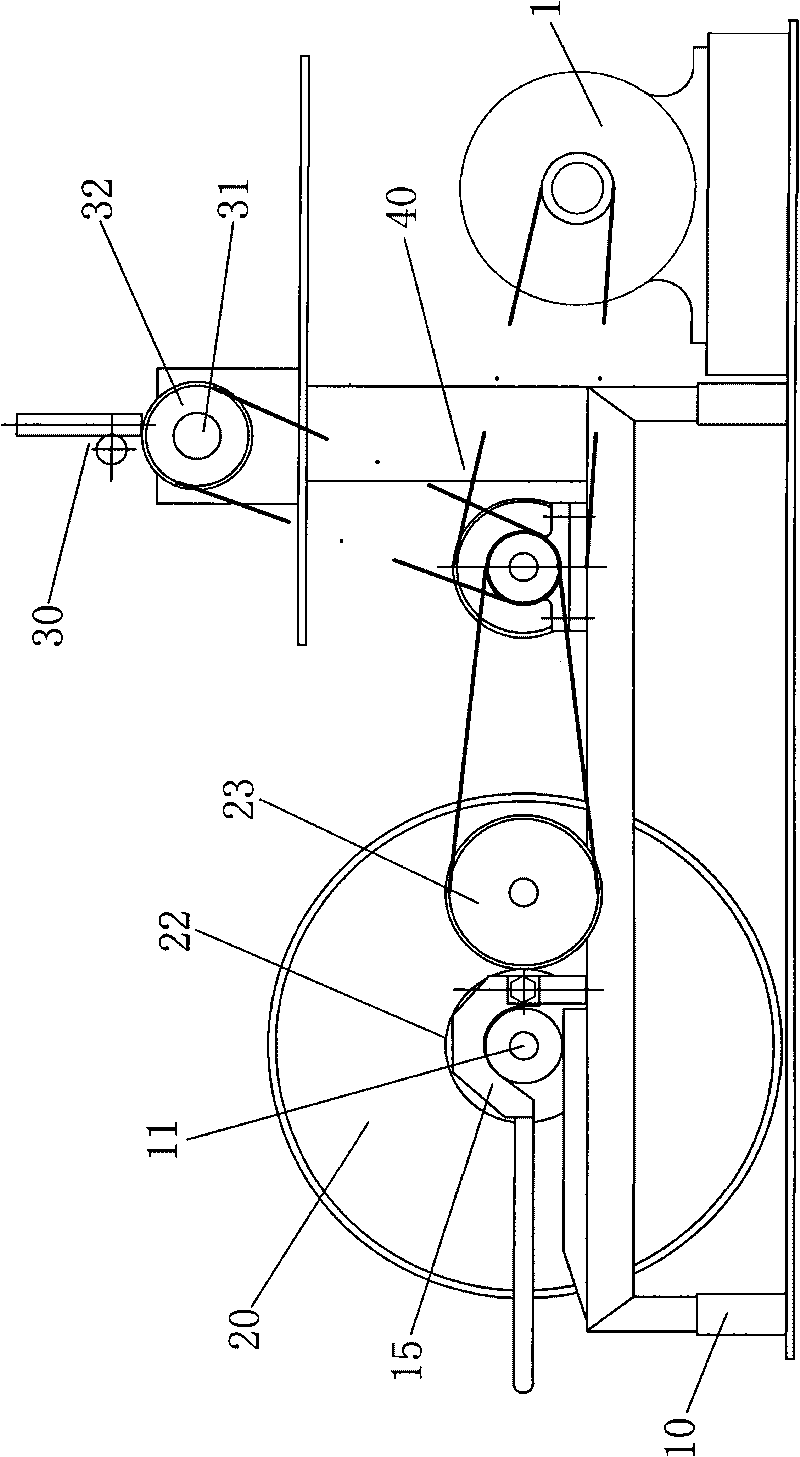

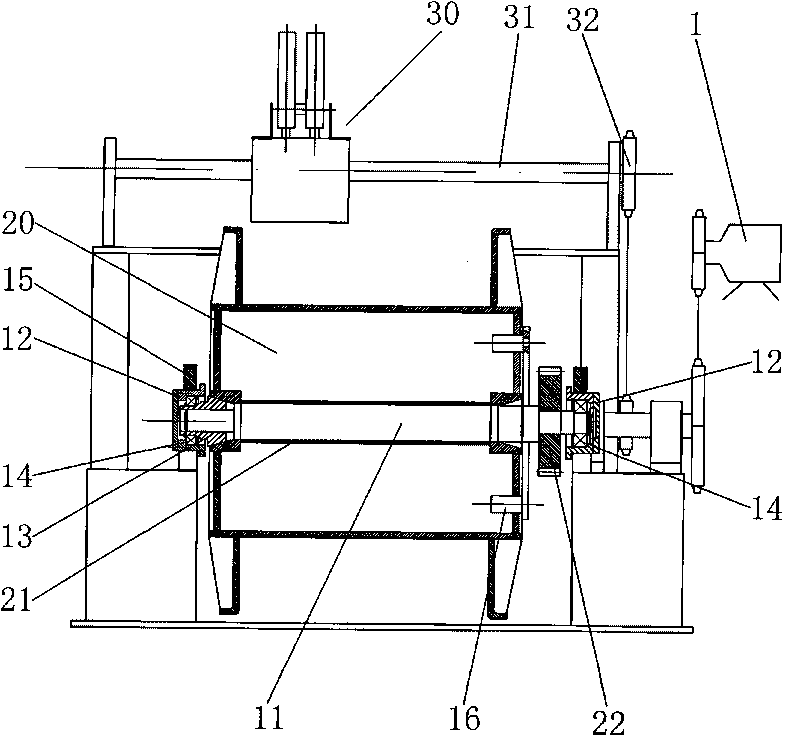

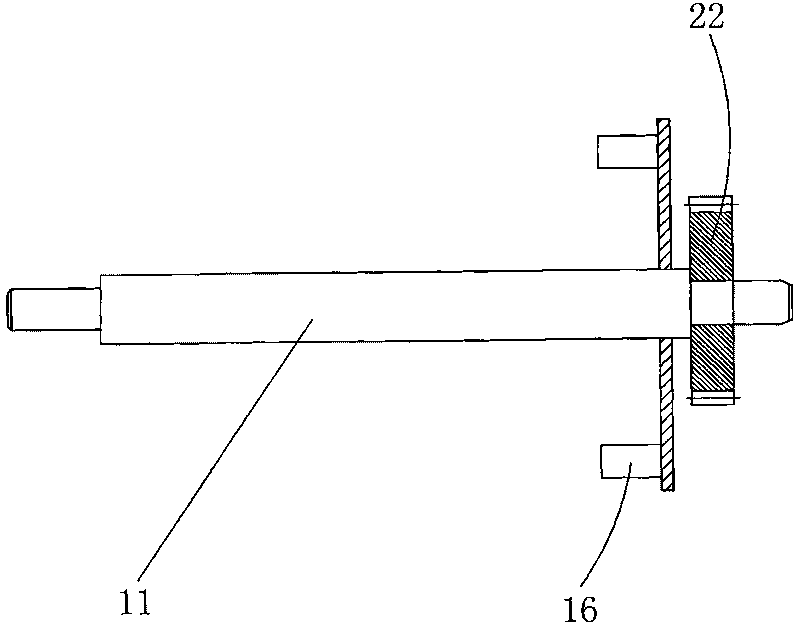

[0017] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-3 :

[0018] Recycling steel wire take-up machine, the I-shaped wheel 20 that winds up the wire on the frame 10 is rotated by the connecting mechanism, and a polished rod cable puller 30 is provided on one side of the I-shaped wheel 20, and the described I-shaped wheel 20 and the polished rod row The threader 30 is driven by the motor 1 and the transmission.

[0019] The above-mentioned connection mechanism is: on the frame 10, an axle seat 12 is installed through a pressure handle 15, and the axle seat 12 is sleeved with a wheel shaft 11, and a movable wheel inner sleeve 13 is arranged between the axle seat 12 at one end of the wheel axle 11 and the wheel axle 11 , a bearing 14 is provided between the inner sleeve 13 of the live wheel and the shaft seat 12; a bearing 14 is provided between the shaft seat 12 at the other end of the whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com