Computer automated measurement method of solid oxide fuel cell (SOFC) electroconductance

An automatic measurement, electrode conductance technology, applied in measurement devices, measurement of electrical variables, measurement of resistance / reactance / impedance and other directions, can solve the problems of difficult to grasp the accuracy of recorded data, low experimental efficiency, frequent equipment operation, etc., to improve the measurement Efficiency and measurement accuracy, economic benefits, and cost-effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: Realize optional setting of programmable parameter table parameter measurement

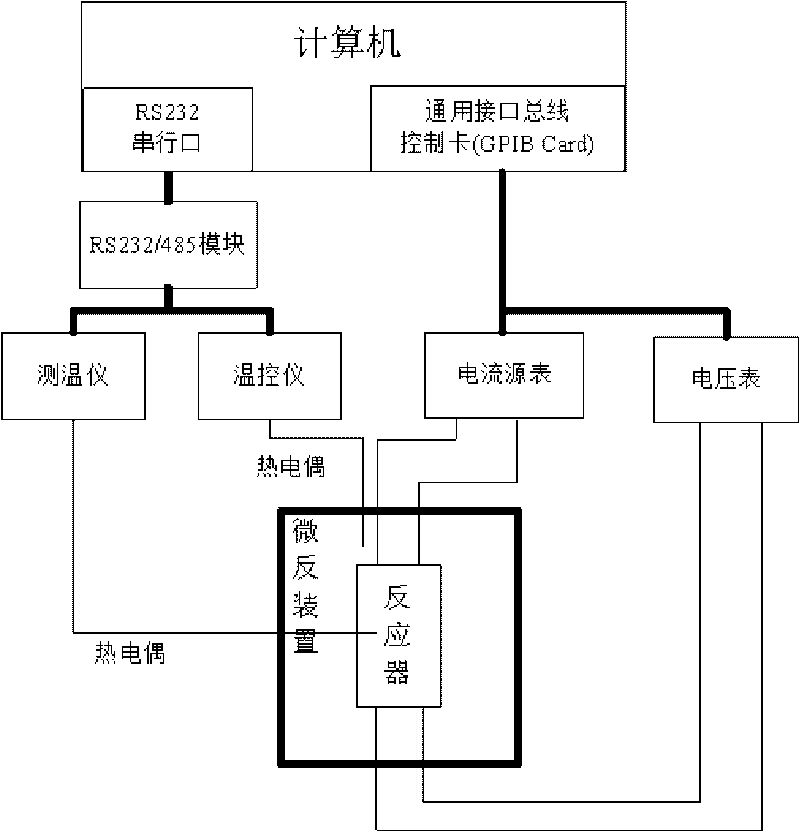

[0017] For the same set of SOFC electrode conductance parameters, the calculated conductance values are different under different temperature environments. In order to automatically measure the conductance d of the SOFC electrode, it is necessary to obtain the temperature environment parameters and calculate the conductance-related parameters of the SOFC electrode in the micro-reflector device during the temperature programming process under the given condition of the electrode current, where the temperature environment parameters include the temperature of the micro-reflector device section Td and reactor temperature Tf, conductance related parameters include micro-reactor cavity voltage E and SOFC electrode voltage U. The programmable parameter table divides these measurement parameters into two types: measurement parameters and optional measurement parameters. Among them,...

Embodiment 2

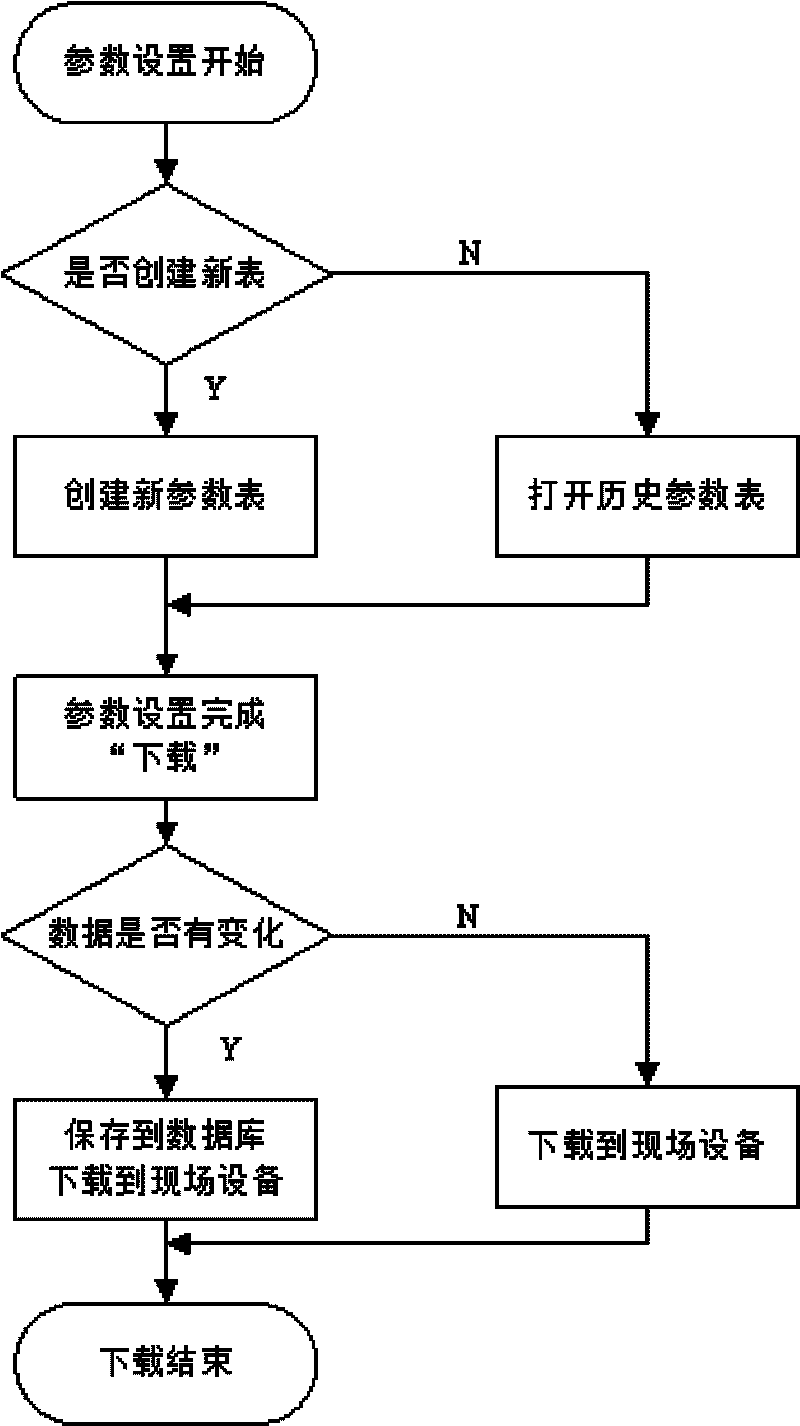

[0018] Embodiment 2: Realize the multiple selection method of the measurement parameter download function to save data

[0019] By default, the historical parameter table in the database downloaded last time is loaded into the memory and the current table. You can create a new blank table for parameter setting, or select Zhi Chi to load the historical parameter table in the database into the current memory. After the parameter setting is completed, select Naoluecai, update the flag variable (m_bDataChangeFlag) according to the parameter each time, query whether there is any data change in the parameter table, and download it in two ways. One is to transmit the parameters to the database for storage and download and transmit them to the field device for storage at the same time, and the other is to only download and save the parameters without transmitting them to the database for storage. If it is detected as new setting data, save it in the first way, submit and save the pro...

Embodiment 3

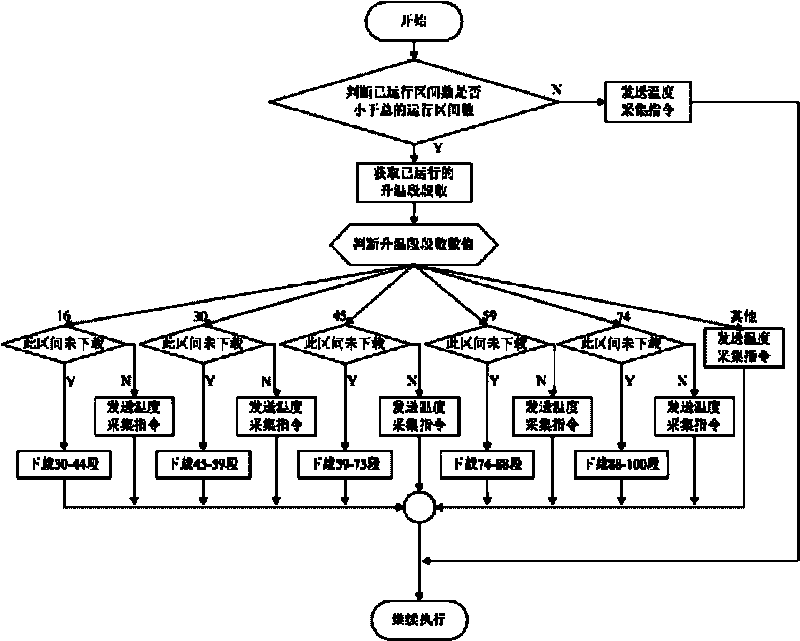

[0020] Example 3: Realize a seamless and continuous programmed heating process with any length of the heating section

[0021] Existing temperature controllers that support computer communication can provide a maximum temperature rise section of 30 sections, and each temperature rise section includes two parameters: segment temperature T and time period C. In order to meet the continuous temperature control requirements of any length of the temperature rise section, the key is to solve When the download parameters are running, there may be a time-dependent phenomenon, so as to ensure the continuity of the download parameters in time. In the present invention, for the programmed temperature increase of more than 30 sections (providing a maximum length of 100 sections), the length of the 30 heating sections in the temperature controller is used as a complete heating area in the program, and on this basis, it is equally divided into two operating intervals , each operating interv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com