Plate type ultrafiltration membrane locking assembly

An ultrafiltration membrane and plate technology, applied in the field of semi-permeable membrane separation devices, can solve the problems of leakage filtration quality and efficiency, difficult to accurately reset, troublesome membrane cleaning, etc. Efficiency and service life effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

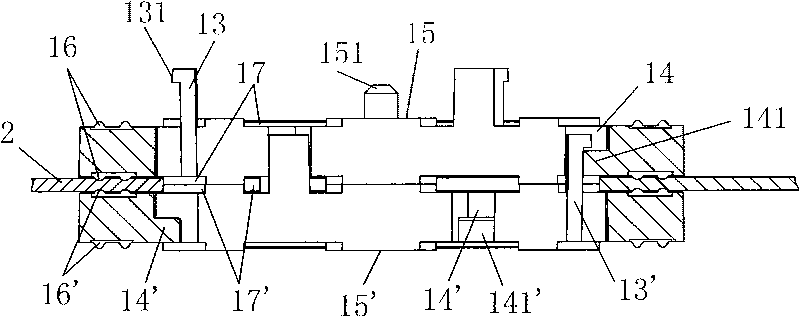

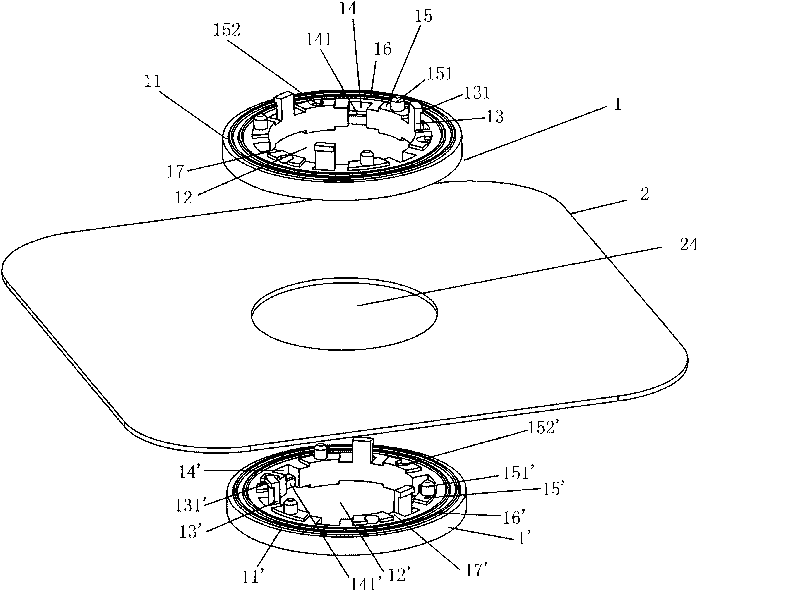

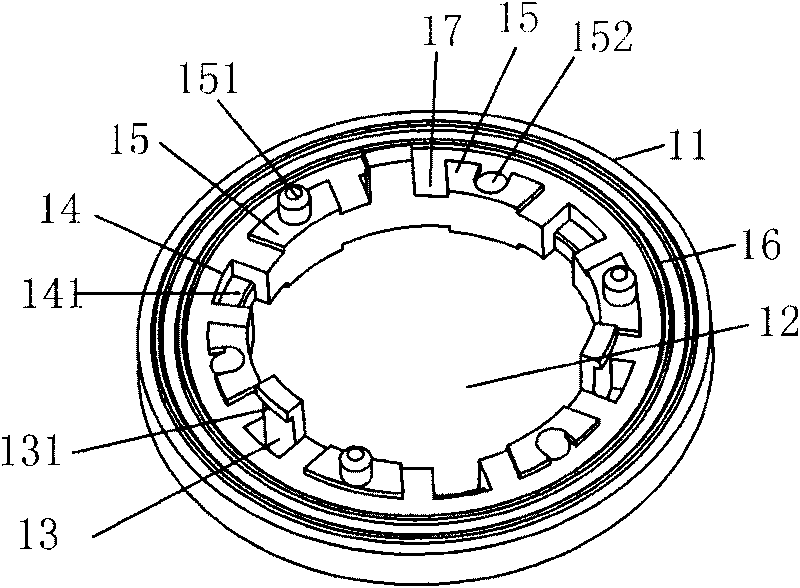

[0013] The present invention will be further described below with reference to the accompanying drawings.

[0014] The membrane element 2 is composed of a first membrane 21, a second membrane 22 and a wire mesh 23 sandwiched between the two membranes. The first and second membranes are laminated with the outer periphery of the wire mesh to form a hemming 25. The central position of the element is provided with a perforation 24 passing through the first and second membranes and the screen. Both the first membrane 21 and the second membrane 22 of the membrane element 2 are made of a semi-permeable membrane material with a smooth surface, and the wire mesh 23 is made of PP or PET. The locking plate 1 has an annular body 11 whose outer diameter is larger than the diameter of the perforation 24 of the membrane element and whose inner diameter is smaller than the diameter of the perforation 24 of the membrane element. On the front and back of the annular body 11, there are several f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com