Hydraulic pressure butterfly valve shaft sleeve installation machine and installation method

A butterfly valve shaft and installation machine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of irregular manual operation, difficult to accurately locate, reduce production efficiency, etc., to improve working conditions and environment, eliminate Heavy physical labor, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

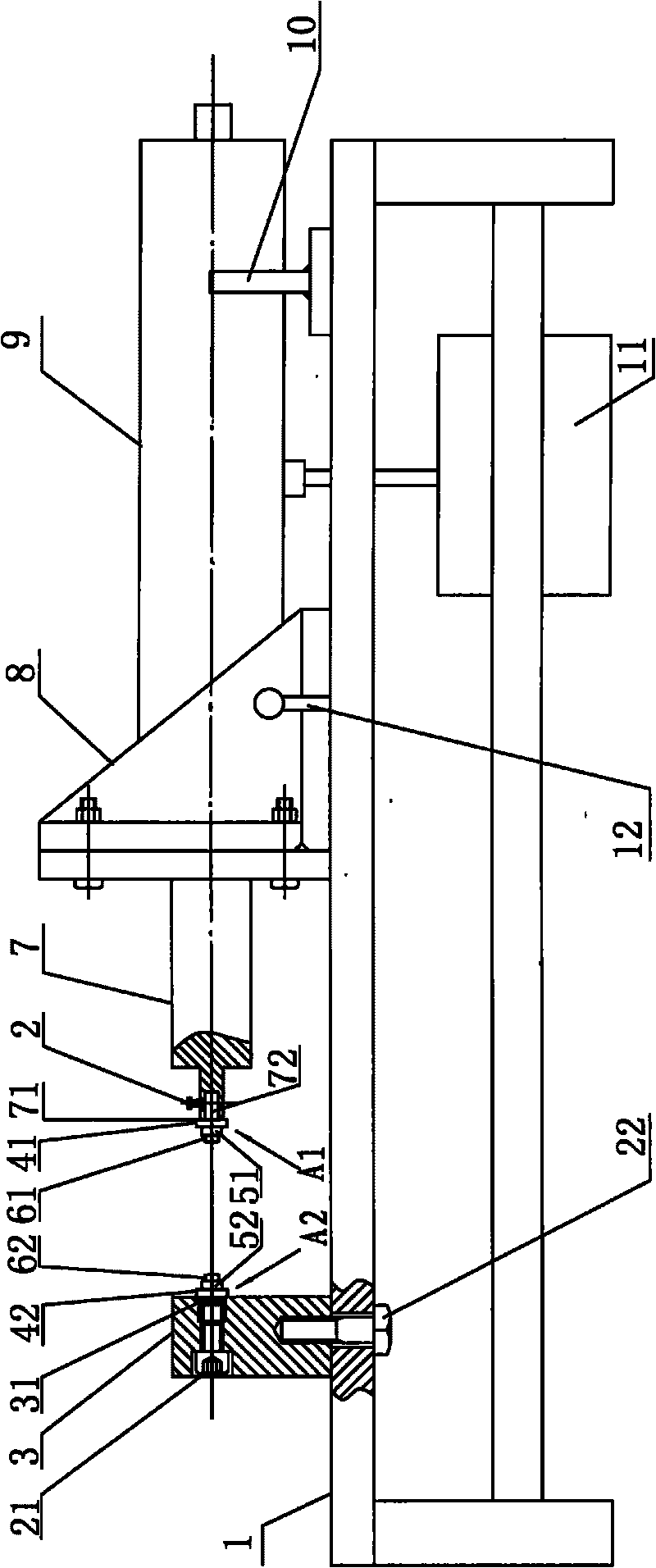

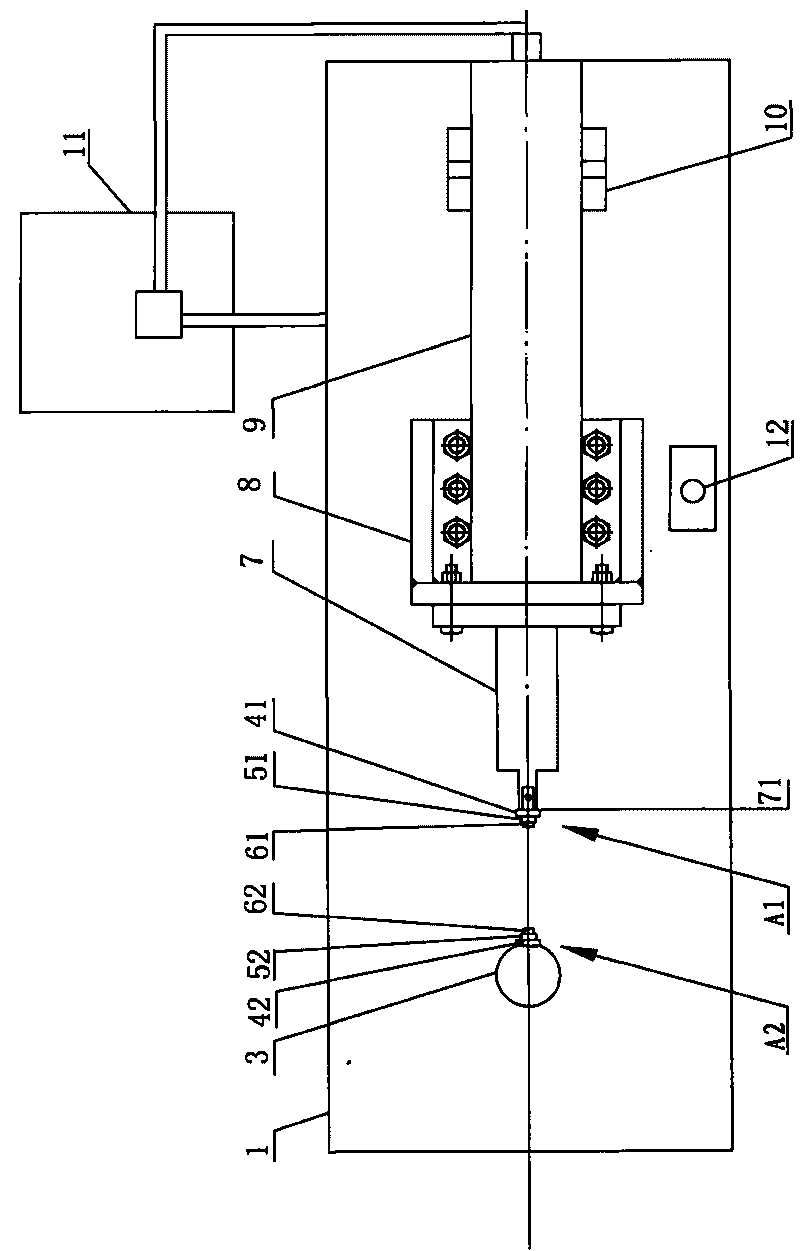

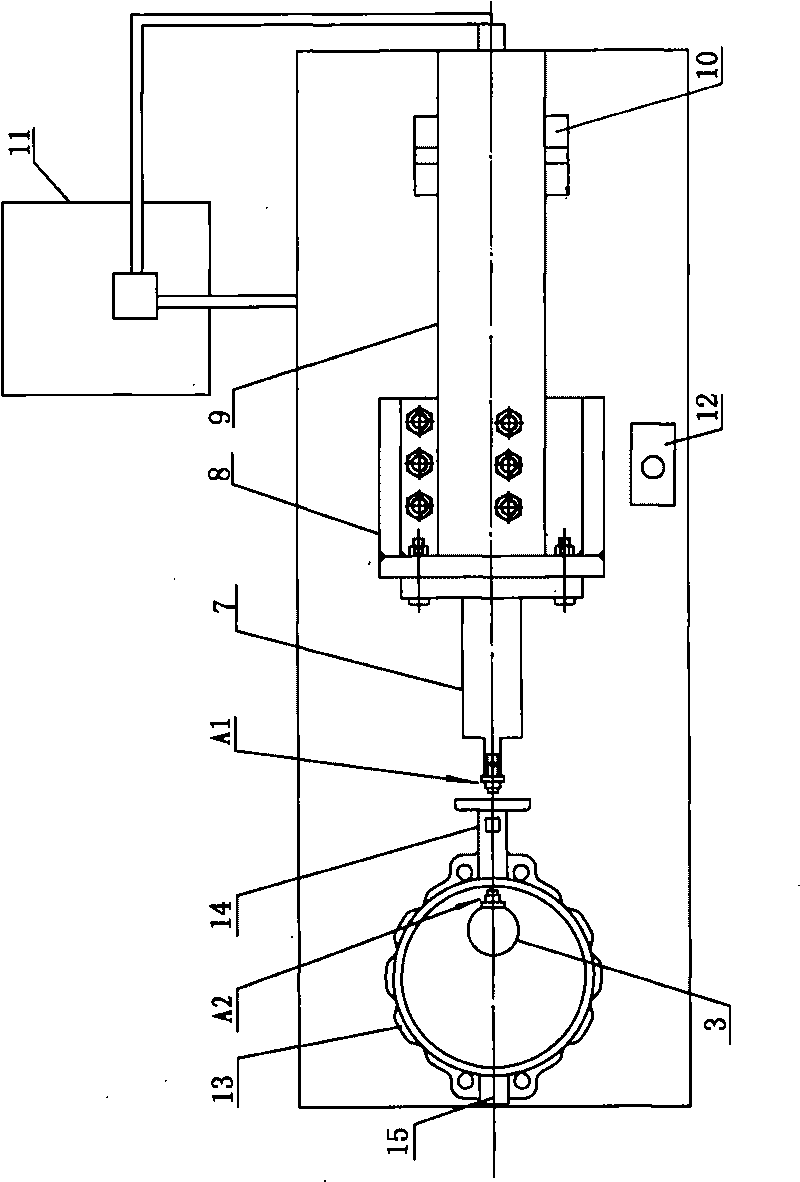

[0026] Figure 1-Figure 7 It shows a hydraulic butterfly valve shaft sleeve installation machine and its application diagram; the installation machine includes a workbench 1, which is characterized in that the above workbench is a rectangular stand, and is arranged and fixed at symmetrical intervals from right to left center along the longitudinal direction of the upper 1 workbench. The hydraulic cylinder 9 and the positioning block 3 on the work surface, the above-mentioned hydraulic cylinder is placed opposite to the positioning block 3 with its piston rod 7, and the end face 71 of the piston rod and the end face of the positioning block opposite to it are respectively arranged coaxially for the upper and lower valves. The neck sleeves 16, 19 are respectively pressed into the detachable right and left positioning pins A1, A2 in the upper and lower valve neck shaft holes 141, 151; Left flange 41,42, right and left shoulders 51,52 and right and left pin shaft ends 61,62, right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com