Combined cam shaft torsion detection device of engine

A technology of torque detection and camshaft, applied in measuring devices, torque measurement, power measurement, etc., can solve the problems of extensive processing technology, time-consuming and laborious operation, low efficiency, etc., and achieve fast and easy clamping and positioning work, and detection efficiency. High, easy-to-change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

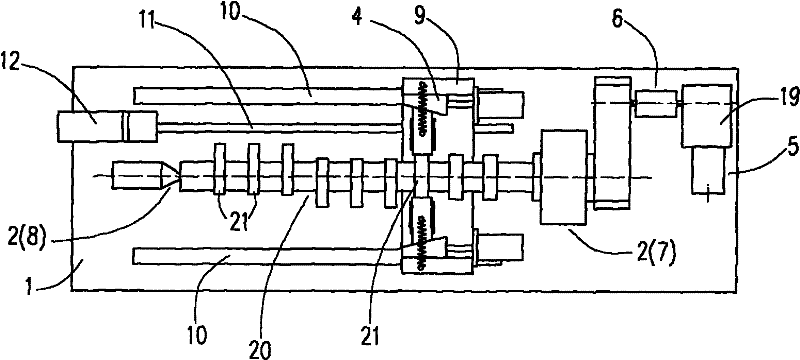

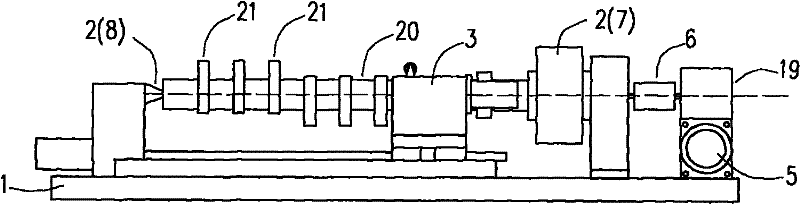

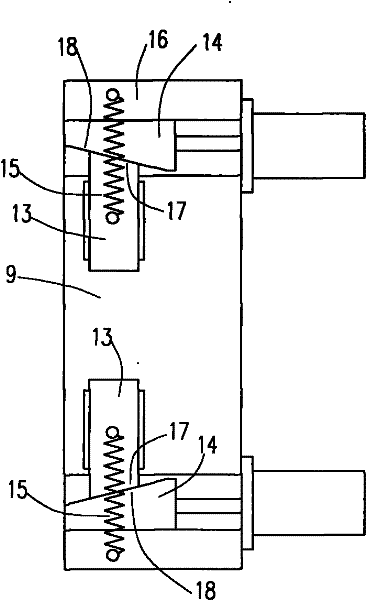

[0018] Such as Figure 1 to Figure 4 As shown, an embodiment of the present invention includes a machine base 1, a pneumatic clamping mechanism 2, a sliding plate mechanism 3, a pressure head mechanism 4, a first servo motor 5 for providing detection torque, and a torque sensor 6. The pneumatic clamping mechanism 2 includes a pneumatic chuck 7 and a pneumatic tip 8 that can drive the detected camshaft to rotate around the mandrel; the slide mechanism 3 includes a slide seat 9, a guide rail 10, a screw group 11 and a second servo motor 12, the The sliding plate base 9 is installed on the machine base 1 through the guide rail 10 and the lead screw group 11, and the second servo motor 12 controls the feeding of the sliding plate base 9; the pressure head mechanism 4 includes a pair of pressure head blocks 13 and a pair of pneumatic Wedge block 14, said pressure head mechanism 4 is symmetrically arranged on slide plate seat 9 relative to the axis of the detected camshaft, slide pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com