A desulfurization process and device for quickly establishing a stable circulating fluidized bed

A circulating fluidized bed and desulfurization device technology, which is applied in the direction of combined devices, chemical instruments and methods, and dispersed particle separation, can solve problems such as fluidized bed collapse, reaction tower wall sticking, and spray gun clogging to reduce desulfurization costs , reduce the frequency of tower sticking, and reduce the effect of calcium-sulfur ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

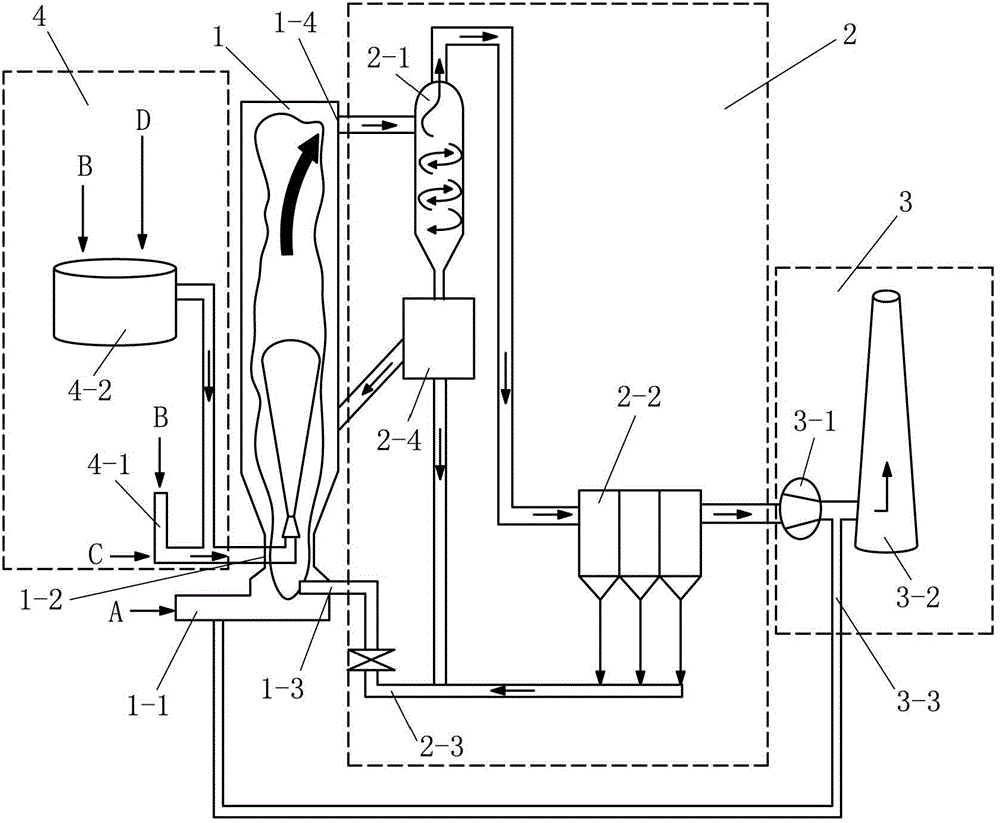

[0020] Hereinafter, the desulfurization process and device for quickly establishing a stable circulating fluidized bed of the present invention will be described in detail with reference to the accompanying drawings.

[0021] In the circulating fluidized bed desulfurization process, the three main problems that are most likely to occur include the collapse of the fluidized bed, the clogging of the spray gun, and the wall sticking or even blocking of the reaction tower. The reasons for the above phenomena are as follows:

[0022] A. Fluidized bed collapse: Due to the serious loss of control of the gas-solid two-phase in the reaction tower, the gas flow in the tower is unevenly distributed, and there are too many solid substances in the tower, which cannot be circulated and the circulation balance is destroyed.

[0023] B. Wall sticking or even blockage of the reaction tower: due to the serious adhesion of the slurry in the reaction tower on the tower wall, there are too many liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com