Multidirectional stressed plastic tensile grate and manufacturing method thereof

A multi-directional force and production method technology, applied in excavation, other household appliances, infrastructure engineering and other directions, can solve the problems of node damage, failure to reinforce reinforcement, and difficulty in overall strengthening, and achieve tear damage. The effect of reduced probability, reasonable stress state, and enhanced structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

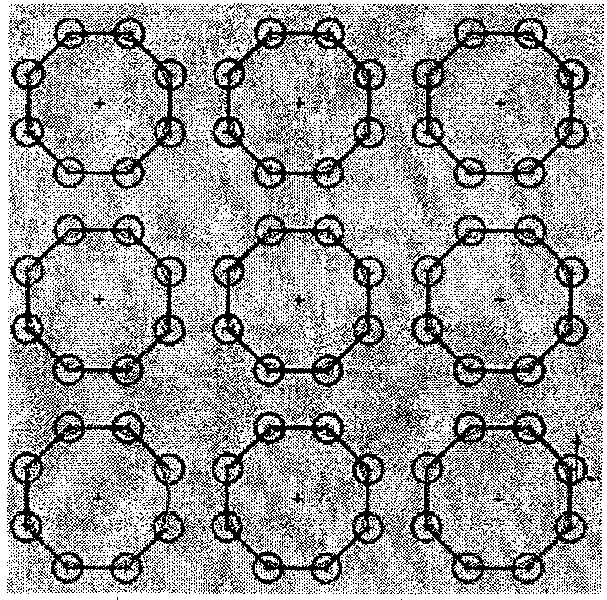

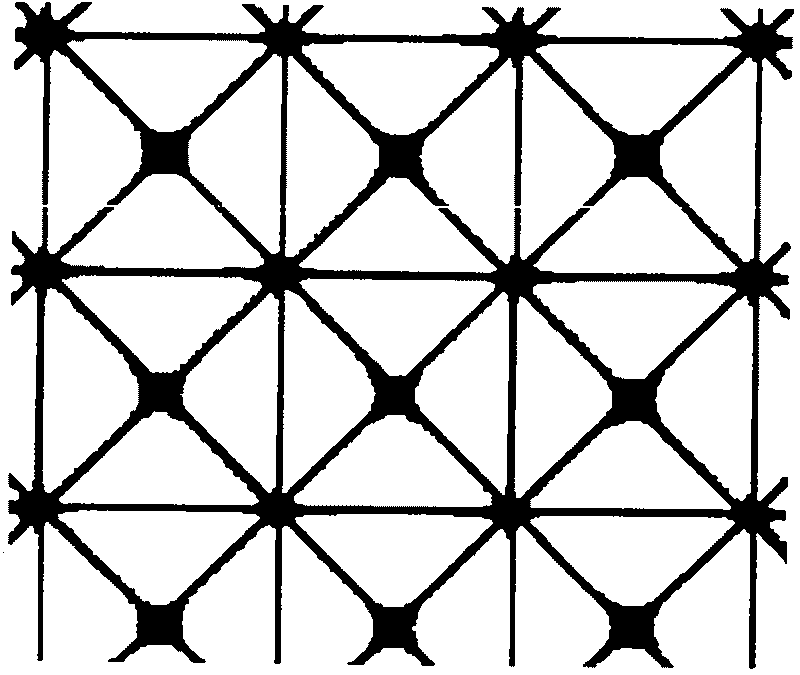

[0026] Such as figure 1 As shown, a plastic plate with a hole array composed of identical units extending horizontally and vertically is formed by extrusion, and each unit contains 8 holes arranged in an octagon. The 8 Each hole is located at the 8 vertices of the octagon. Specifically, the centers of the 8 holes are respectively located at the 8 vertices of the rhombus. The diameter of all the holes is 5mm, and the row spacing between each octagonal unit is 9mm. The row distance is 10 mm, and the above-mentioned obtained plastic sheet provided with hole arrays is stretched longitudinally and transversely by approximately 3 times respectively. During the stretching process, due to the difference in the cross-sectional area formed between any two holes, the There will be a difference in the carrying capacity, and the smaller cross-sectional area is easy to be pulled apart, while the larger cross-sectional area is not easy to be pulled apart, thus forming such a figure 2 Each ...

Embodiment 2

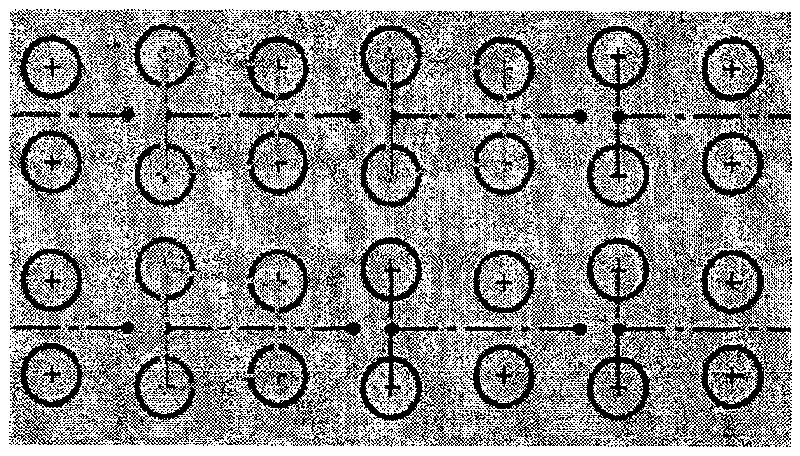

[0028] Such as image 3 As shown, a hole array composed of the same units extending horizontally and vertically is punched out on the plastic sheet, and each unit contains 4 holes arranged in a trapezoidal shape, and the 4 holes are respectively located in the trapezoidal The 4 vertices of , specifically the centers of the 4 holes are located at the 4 vertices of the trapezoid, and the diameter of all the holes is 5mm, and the row and column distances between two adjacent trapezoidal units are 10mm. The upper bottom, lower bottom, and height are 10mm, 11mm, and 10mm respectively. The above-mentioned obtained plastic sheet provided with hole arrays is stretched vertically and horizontally by approximately 3 times. During the stretching process, due to the gap between any two holes, The cross-sectional area formed between them is different, and the bearing capacity will be different during the processing. The smaller cross-sectional area is easy to be pulled apart, while the lar...

Embodiment 3

[0030] Such as Figure 5 As shown, a plastic plate with a hole array composed of the same units extending horizontally and vertically is formed by extrusion. Each unit contains 4 holes arranged in a rhombus shape. The 4 holes They are respectively located at the 4 vertices of the rhombus, specifically, the centers of the 4 holes are respectively located at the 4 vertices of the rhombus, and the diameter of all the holes is 4mm, the row spacing between each rhombus unit is 10mm, and the column spacing is 10mm. The above-mentioned plastic sheets provided with hole arrays are approximately four times stretched vertically and horizontally simultaneously. During the stretching process, due to the difference in the cross-sectional area formed between any two holes, there will be differences in the bearing capacity during processing. , the one with a smaller cross-sectional area is easy to be pulled apart, while the one with a larger cross-sectional area is not easy to be pulled apar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com