Production line for automatic boxing of wall and floor tiles

A technology of automatic boxing and wall and floor tiles, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve problems such as corner protection and brick body skew, failure to meet actual production requirements, misoperation, etc., and achieve the effect of avoiding edge collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The brick loading mechanism, cardboard extracting mechanism, carton forming mechanism and palletizing mechanism in the automatic packing production line for wall and floor tiles will be described in detail below.

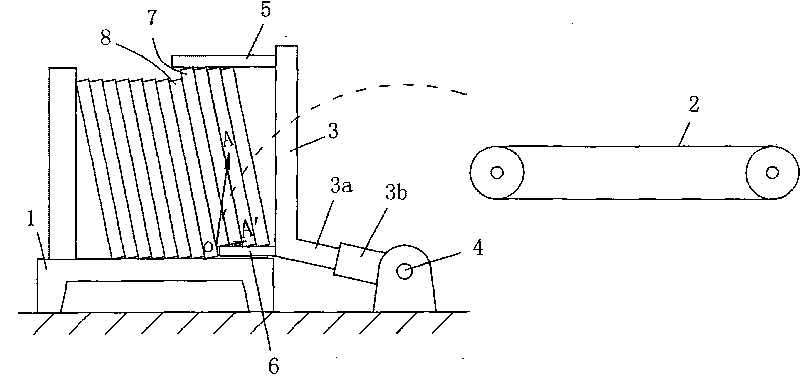

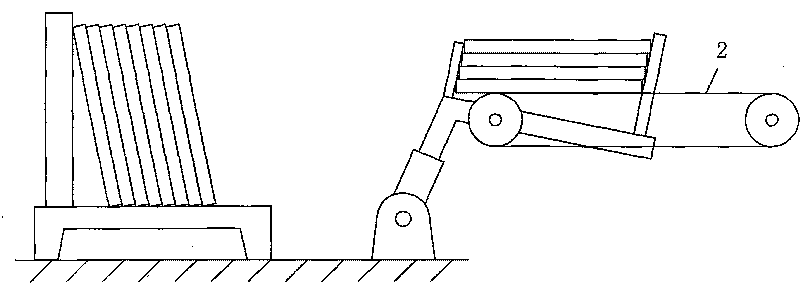

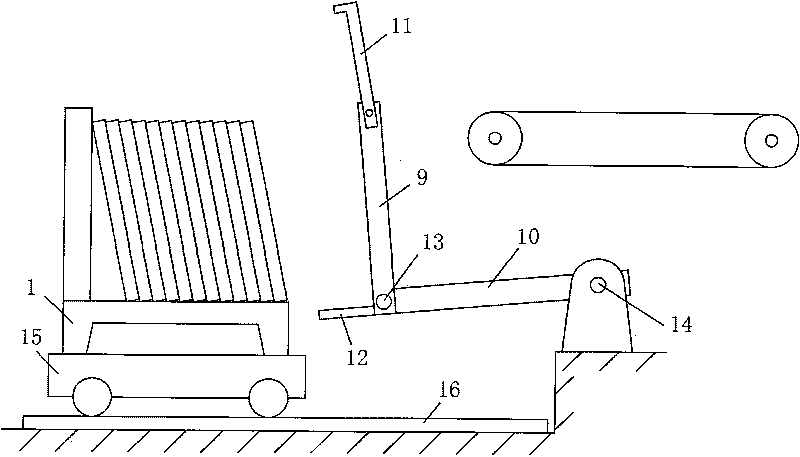

[0048] Embodiment 1 of upper brick mechanism is as figure 1 shown. The brick loading mechanism includes a brick rack 1 for holding bricks, a conveying line 2 for transporting bricks, and a manipulator for transferring bricks on the brick rack 1 to the conveying line 2 . The manipulator of this embodiment has only one section of "L" shaped swing arm 3, and the position of the swing arm close to the swing shaft 4 is divided into two telescopic sections 3a, 3b. The swing arm 3 is connected with claws 5, 6 for clamping the brick body. Claws 5 and 6 clamp the brick body from the upper and lower sides of the brick body, and can clamp four brick bodies at a time. After the claws clamp the brick body, the swing arm 3 drives the brick body to rotate around the swin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com