Ballastless track rail finely-tuned vehicle

A ballastless track and fine-tuning technology, which is applied to tracks, track laying, track maintenance, etc., can solve the problems of long construction time and high construction cost, and achieve the effect of improving utilization rate, improving work efficiency and shortening construction operation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

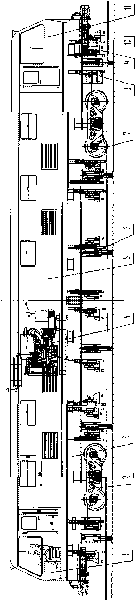

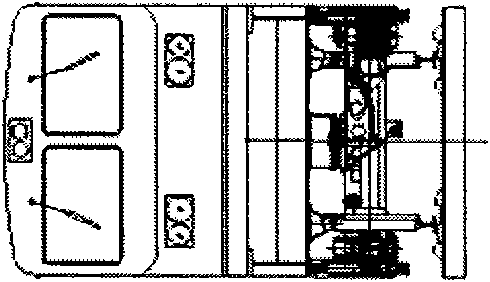

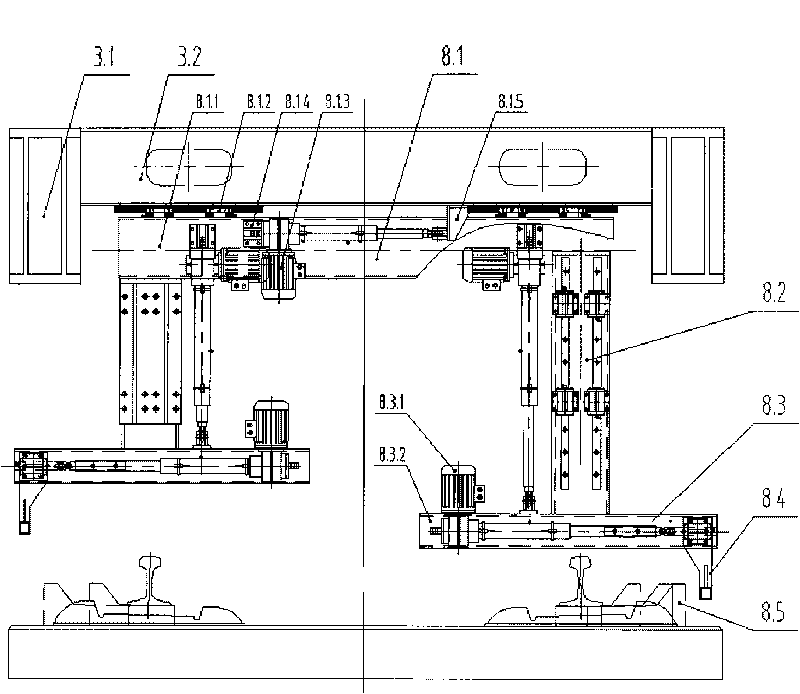

[0030] figure 1 It is a ballastless rail fine tuning car disclosed by the invention. The power chamber 4 installed in the compartment 5 provides power sources for all actuators, and the power chamber 4 is composed of a generator set, a hydraulic pump station and an air compressor. Both sides of the vehicle frame 3 are provided with several supporting legs 6 to realize the smooth lifting of the fine-tuning car. Two sides of the frame 3 are provided with a number of outriggers 6 to realize the smooth lifting of the fine-tuning car; a number of top iron manipulators 8, grasping manipulators 9 and positioning manipulators 10 are fixed under the beam 3.2 of the car frame 3, and the above manipulators cooperate with each other to adjust the rails Shape. The front and rear bogies (2, 7) of the lower part of the vehicle body provide a walking function. The front and rear cabs (1, 11) are equipped with control centers and interlocking devices, and each cab can independently complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com