Coating method of UV insulation moisture resisting agent

A moisture-proofing agent and coating technology, applied in the direction of tube/light screen manufacturing, etc., can solve the problems of large variation in the width of UV glue, long flow time, inability to cover the UV glue evenly, and achieve good coating uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

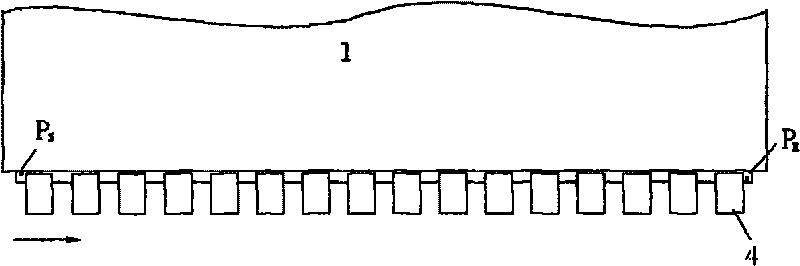

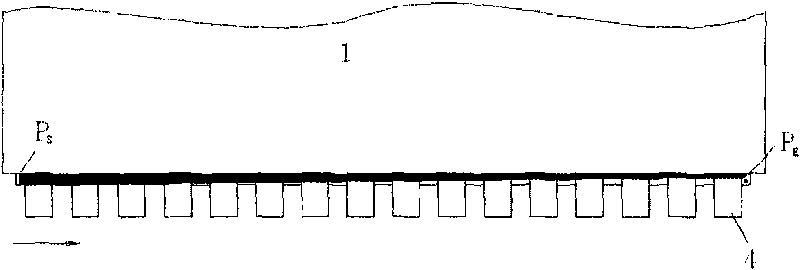

[0029] like image 3 As shown, the control point P starts on the coated side of the lower glass 12 of the PDP screen S and end control point P E Add a control point P between 1 , we call P1 For the first insertion control point, when the control point is set, the first insertion control point P 1 Relative to the starting control point P S Move S " towards the edge of the bottom glass 12 of the PDP screen 1 = 0.3mm, will end the control point P E relative to the first inserted control point P 1 Move S " towards the edge of the bottom glass 12 of the PDP screen 2 = 0.5mm, through the reasonable setting of the relative position relationship between the coating point and the edge of the lower glass 12 of the PDP screen, the UV insulating and moisture-proofing agent applied afterward can still flow quickly due to the short flow time. At the edge of the upper glass 11 of the PDP screen, at the same time, the problem that the UV insulating and moisture-proof agent flows slowly...

specific Embodiment 2

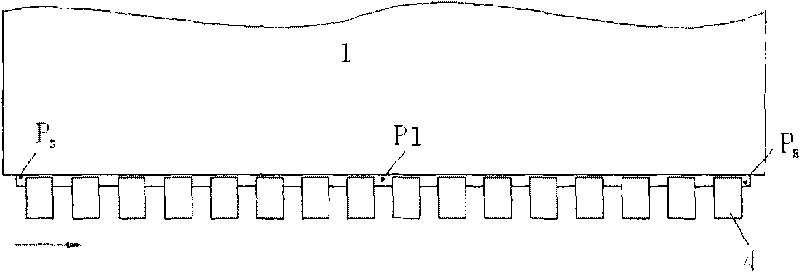

[0032] Such as Figure 5 As shown, the control point P starts on the coated side of the lower glass 12 of the PDP screen S and end control point P E increase P 1 and P 2 Two control points, we call P 1 is the first inserted control point, called P 2 For the second insertion control point, when the control point is set, the first insertion control point P 1 Relative to the starting control point P S Move S " towards the edge of the bottom glass 12 of the PDP screen 1 =0.2mm, insert the second control point P 2 relative to the first inserted control point P 1 Move S " towards the bottom glass 12 edge of PDP screen 2 =0.3mm, end control point P E point relative to the second inset control point P 2 Move S " towards the edge of the bottom glass 12 of the PDP screen 3 = 0.4mm, through the reasonable setting of the relative position relationship between the coating point and the edge of the lower glass 12 of the PDP screen, the UV insulating and moisture-proofing agent a...

specific Embodiment 3

[0035] Such as Figure 6 As shown, the control point P starts on the coated side of the lower glass 12 of the PDP screen S and end control point P E increase P 1 ,P 2 and P 3 Three control points, we call P 1 is the first inserted control point, called P 2 is the second insertion control point, called P 3 For the third insertion control point, when the control point is set, the first insertion control point P 1 Relative to the starting control point P S Move S " towards the edge of the bottom glass 12 of the PDP screen 1 =0.1mm, insert the second control point P 2 relative to the first inserted control point P 1 Move S " towards the bottom glass 12 edge of PDP screen 2 =0.2mm, insert the third control point P 3 point relative to the second inset control point P 2 Move S " towards the edge of the bottom glass 12 of the PDP screen 3 = 0.3mm, will end the control point P E point relative to the third inset control point P 3 Move S " towards the edge of the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com