Denim warp yarn dyeing method and dyeing device adopted by same

A dyeing method and a technology of a dyeing device, which are applied in the field of denim dyeing, can solve problems such as uneven dyeing, achieve good white core effect, improve the scope of application, and improve the effect of rubbing fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

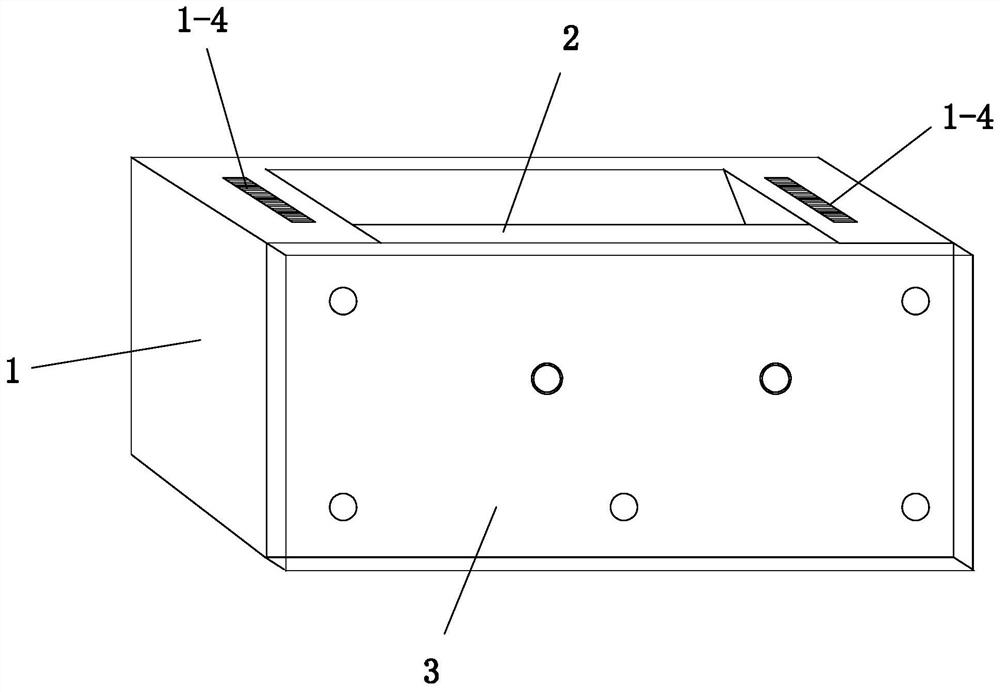

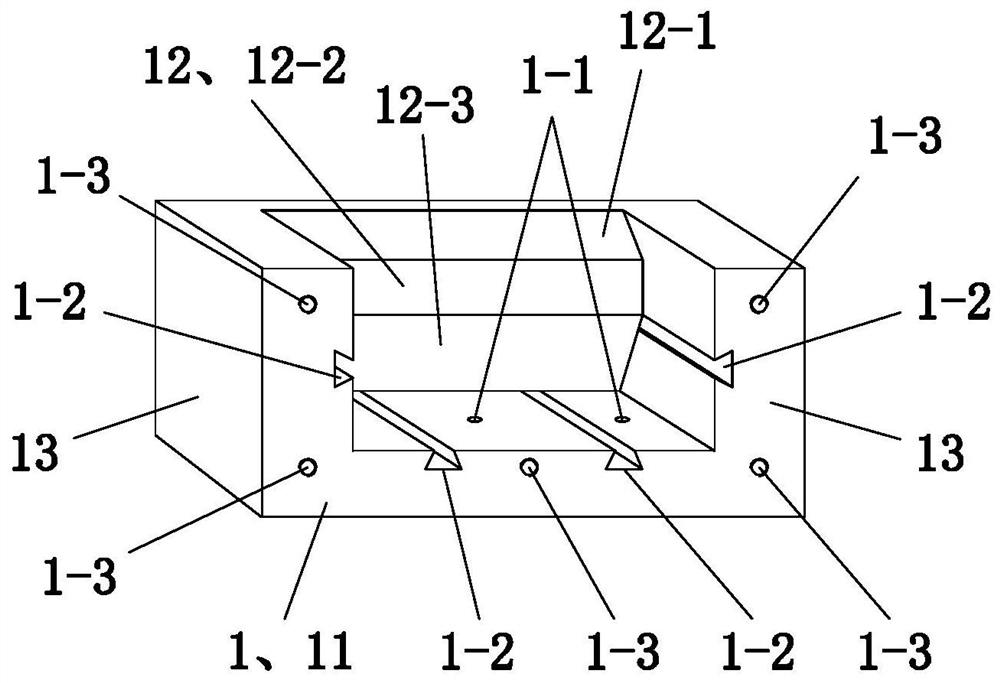

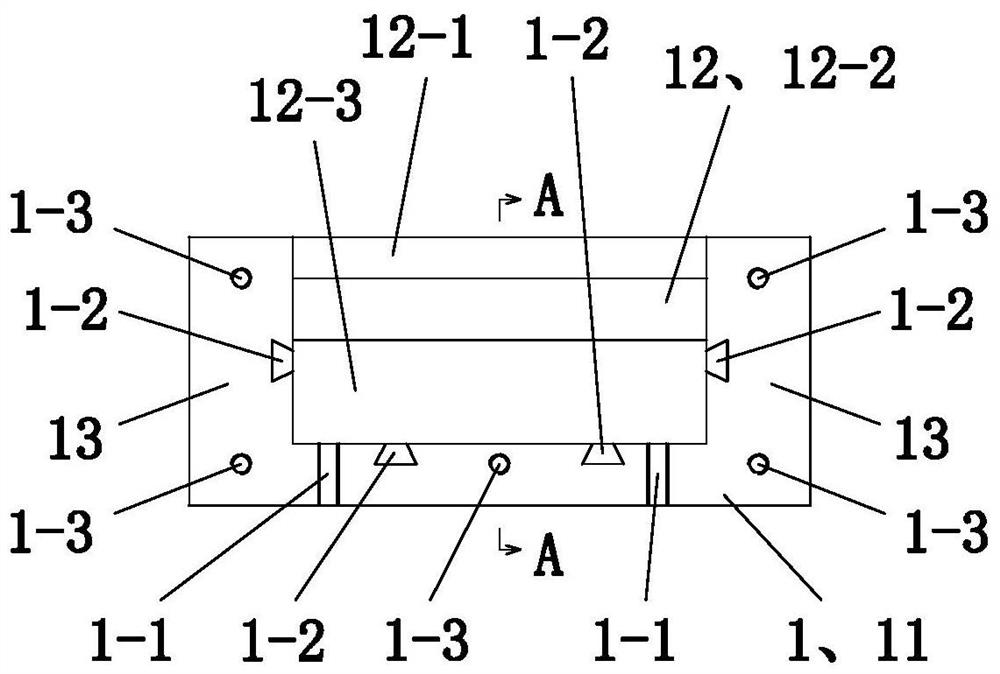

Image

Examples

Embodiment 1)

[0049] The denim warp yarn dyeing method of the present embodiment is as follows:

[0050] ①Stir and mix the dyeing liquid and nitrogen in the gas-liquid mixing device according to the volume ratio of 1:10 to form a gas-liquid mixture, and then press the gas-liquid mixture into the dyeing device from the feed port 1-1 at a certain pressure, and Applied through the coating slot to the denim warp yarns.

[0051] The composition of the dye liquor in this embodiment is as follows: surfactant 30g / L (equivalent to 3%), penetrant 5g / L (equivalent to 0.5%), pre-reduced indigo dye 150g / L (equivalent to 15%), and the rest are water.

[0052] The surfactant used in this example is AOS14-16 [that is, sodium C14-16 alkenyl sulfonate], and the penetrant is SAS60. The coating gap of this embodiment is 40mm, and the yarn coverage factor of the denim warp is 75%.

[0053] ② Delayed oxidation of the denim warp yarn coated with the gas-liquid mixture in step ① for 125s in an oxygen-free envir...

Embodiment 2~ Embodiment 7)

[0056] Each embodiment is basically the same as embodiment 1, except that the oxidation time is delayed, see Table 2 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com