Atorvastatin calcium tablet and preparation process thereof

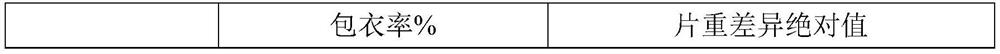

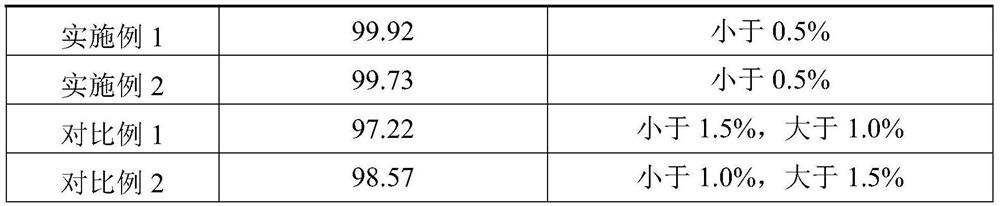

A technology of atorvastatin calcium and fillers, which is applied in the field of atorvastatin calcium tablets and its preparation process, can solve the problems of unfavorable quality control, large difference in tablet weight, non-uniform distribution of coating film, etc., and achieve coating effect The effects of stability, small difference in tablet weight, and uniform film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] An atorvastatin calcium tablet is composed of a core material and a coating film. The core material comprises the following raw materials in parts by weight: 10 parts of atorvastatin calcium, 20 parts of filler, 5 parts of binder, disintegrated 12 parts of lubricant, 3 parts of lubricant; the film is made of hydroxypropyl methylcellulose, nano-titanium dioxide and polyvinylpyrrolidone according to the mass ratio of 3:16:1.

[0029] The above filler is a mixture of erythritol and hydroxypropyl-β-cyclodextrin in a mass ratio of 7:3.

[0030] The above binder is a mixture of hydroxypropyl cellulose and povidone K30 in a mass ratio of 4:1.

[0031] The above-mentioned disintegrant is a mixture of microcrystalline cellulose and croscarmellose sodium in a mass ratio of 9:1.

[0032] The aforementioned lubricant is a mixture of magnesium stearate, talc and silicon dioxide in a mass ratio of 1:1:1.

[0033] The preparation technology of above-mentioned atorvastatin calcium ta...

Embodiment 2

[0039] An atorvastatin calcium tablet is composed of a core material and a coating film. The core material comprises the following raw materials in parts by weight: 10 parts of atorvastatin calcium, 15 parts of filler, 5 parts of binder, disintegrated 8 parts of lubricant and 5 parts of lubricant; the film is made of hydroxypropyl methylcellulose, nano-titanium dioxide and polyvinylpyrrolidone according to the mass ratio of 2:18:1;

[0040] The above filler is a mixture of erythritol and hydroxypropyl-β-cyclodextrin in a mass ratio of 7:3.

[0041] The above binder is a mixture of hydroxypropyl cellulose and povidone K30 in a mass ratio of 4:1.

[0042] The above-mentioned disintegrant is a mixture of microcrystalline cellulose and croscarmellose sodium in a mass ratio of 9:1.

[0043] Above-mentioned lubricant is micropowder silica gel.

[0044] The preparation technology of above-mentioned atorvastatin calcium tablet, comprises the following steps:

[0045] 1) According t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com