Method and device for functional surface coating

A functional surface and coating technology, applied in the field of functional surfaces, can solve problems such as insufficient coating quality and reduced penetration depth, so as to increase the tooth surface area, prevent insufficient coating adhesion, and prevent poor coating quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

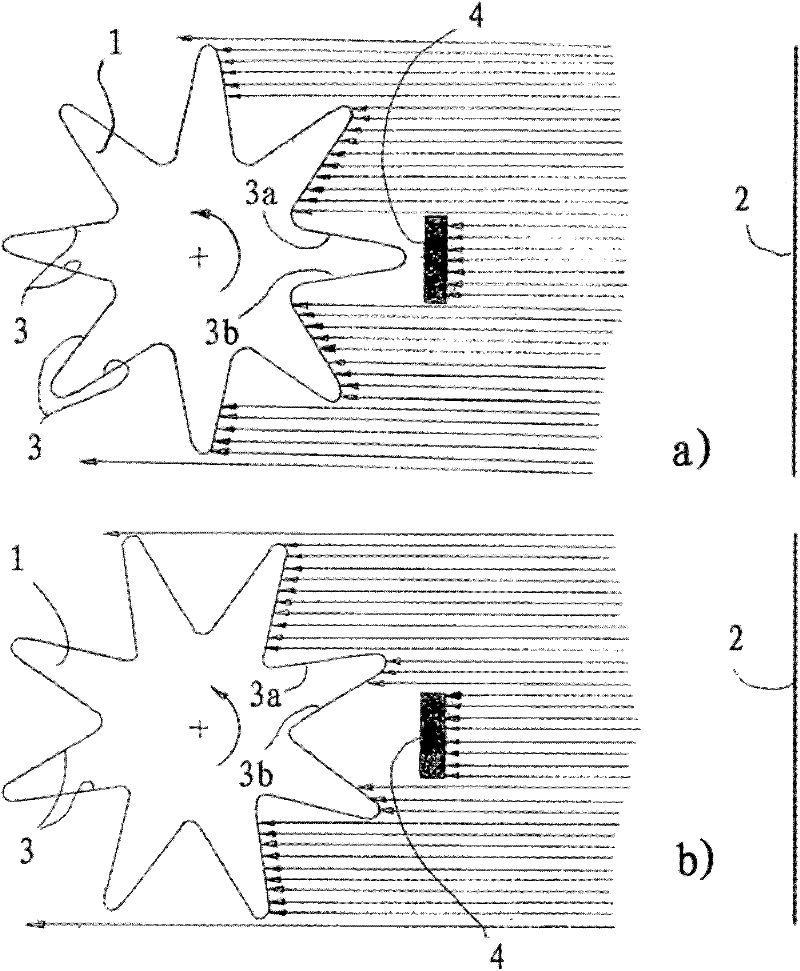

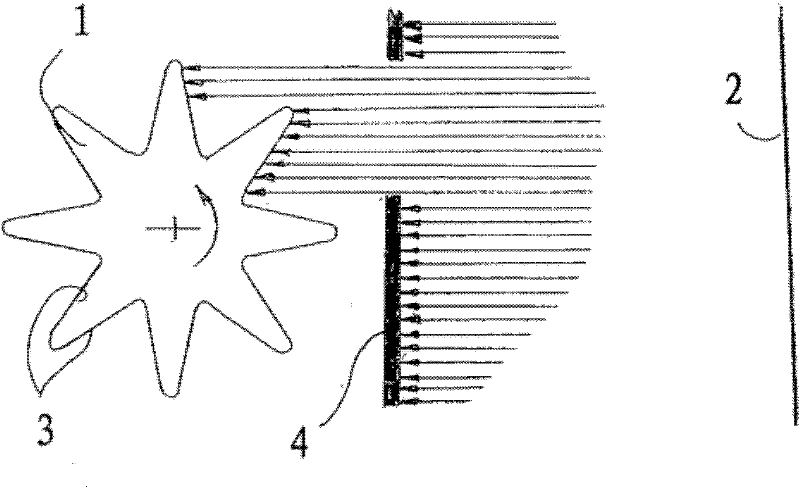

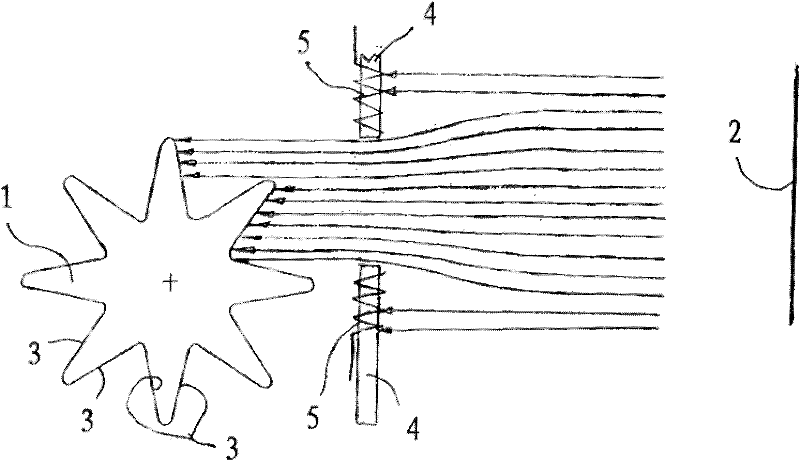

[0015] The coating system shown in the drawing is used for the tooth flank coating of a gear 1 and comprises a coating source 2 which emits a coating in the form of an ionized plasma stream in the direction of the gear 1 The coating beam, which is ideally shown as parallel in the figure, is actually substantially diffuse. In a magnetic and / or electric field, for example by applying a voltage to the gear 1 , the plasma particles are accelerated so strongly that they strike the tooth flank 3 with high kinetic energy and form a firmly adhering, hard coating there.

[0016] During the coating process, the gear 1 rotates about the gear axis, so that all tooth flanks 3 can enter successively into the coating jet of the coating source 1 . At this time, the orientation of the tooth surface 3 relative to the beam direction is changing, so the impact angle of the plasma particles on the tooth surface 3 is also changing. In the region of revolution in which the tooth flanks of the gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com