High-speed grout producing and sending machine supported by stirring pumping coaxial cantilever

A stirring pump and slurry feeding technology, which is applied in the field of stirring and pumping coaxial cantilever support high-speed pulping machines, can solve the problems of inconspicuous fluid on-off, low volume utilization rate, easy aging of pinch pipes, etc., and achieves no fish eyes. effect, improve volume efficiency, improve volume utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

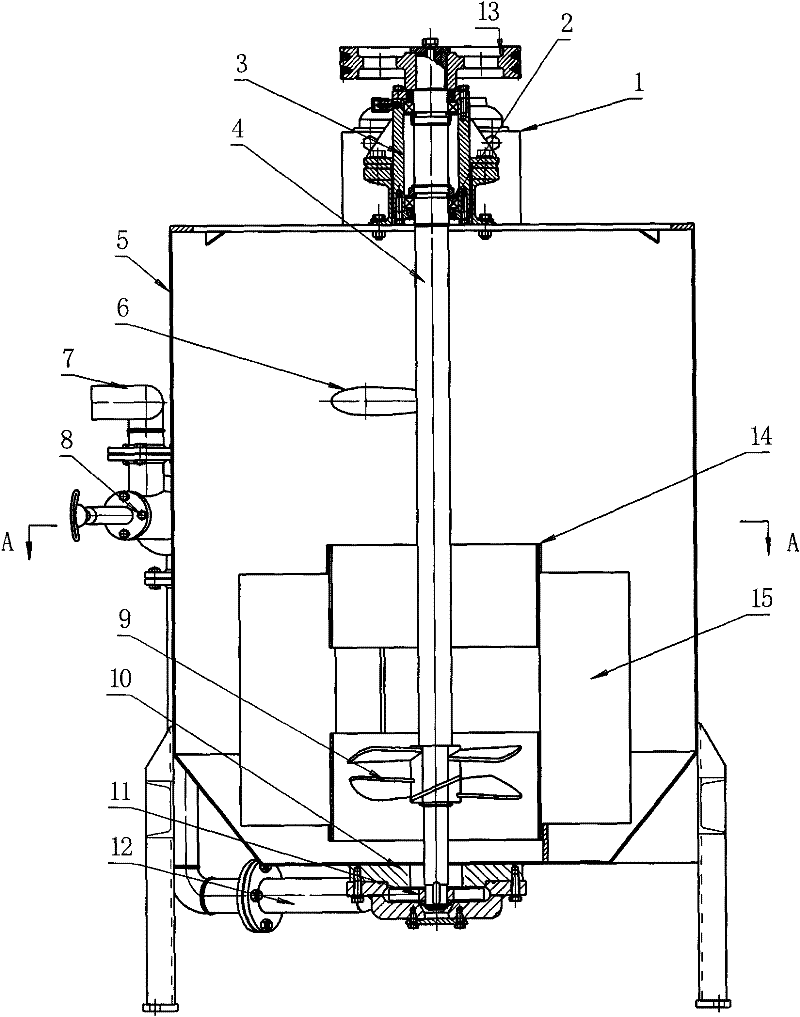

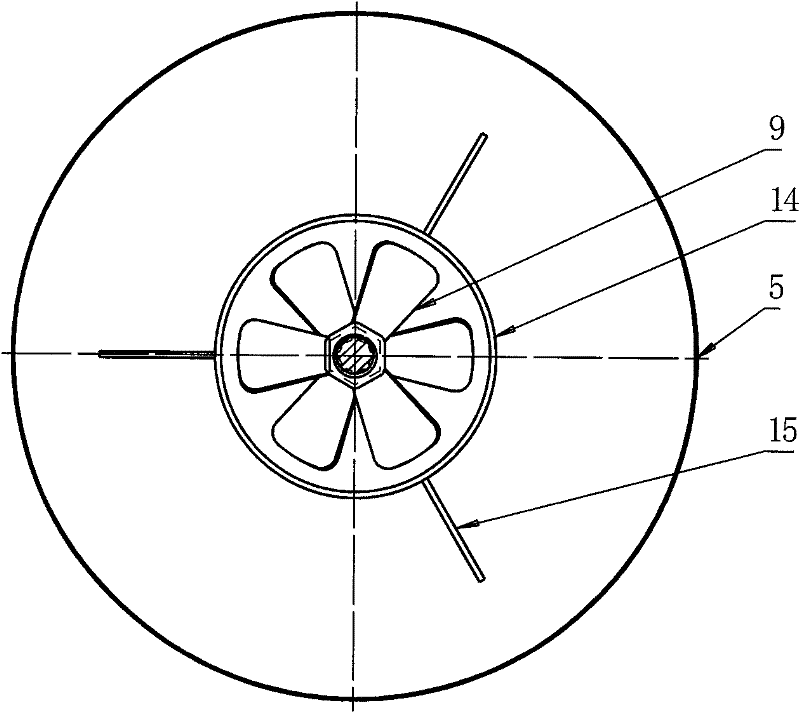

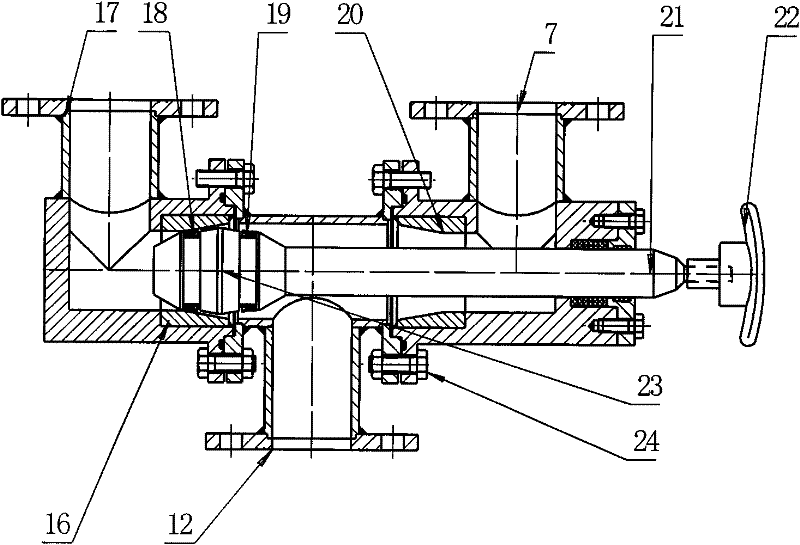

[0039] A stirring and pumping coaxial cantilever supported high-speed pulping machine, the shaft 4 is installed above the barrel 5 through the support sleeve 3, and the support element 2 including the bearing and the sealing element is installed in the support sleeve 3, and the two bearings The distance between them is relatively large, which can effectively overcome the bending stress of the shaft 4 due to the cantilever. The shaft 4 is provided with a transmission mechanism 13. In this example, a belt transmission mechanism is used. The transmission mechanism 13 is connected with the prime mover 1. On the shaft 4 There are two sets of impellers 9, and the lower end of the shaft 4 is also equipped with a pumping impeller 11, which forms a slurry pump 10 with the pump body outside. 14 outer rings are evenly welded with three racemic plates 15 by the circumference. The slurry pump 10 is connected to the three-way pull valve 8 through the slurry outlet pipe 12, and the inlet 17 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com