Portable rice seedling raising mud machine

A technology of rice seedling raising and mud machine, which is applied in the direction of mixer, planting substrate, mixer accessories, etc., can solve the problems of high labor intensity of mud seedling raising, stuck needle leakage when machine inserting, cumbersome operation, etc., and achieves light weight and low cost , The effect of convenient operation and movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

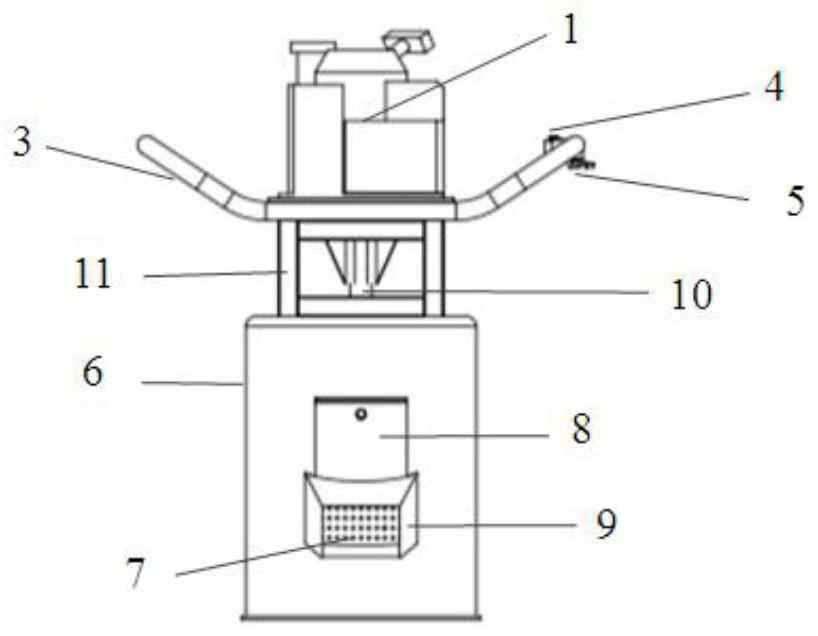

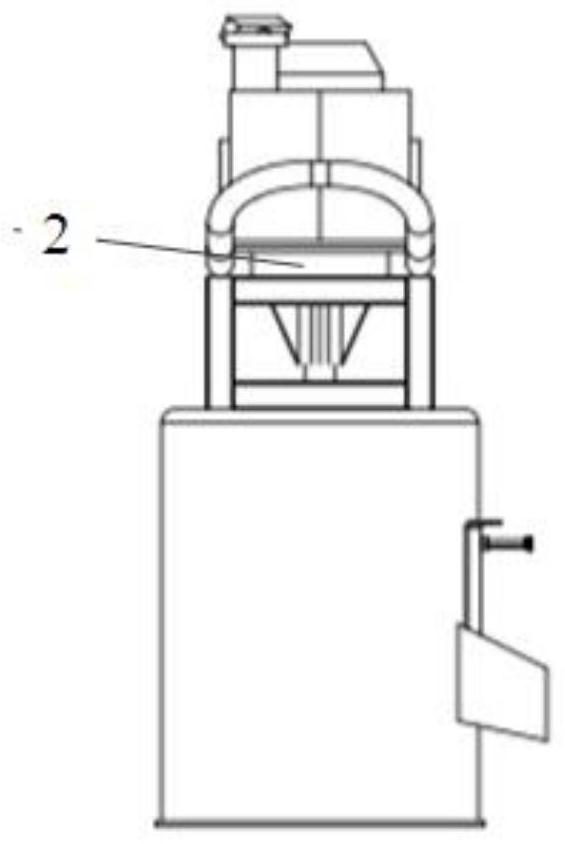

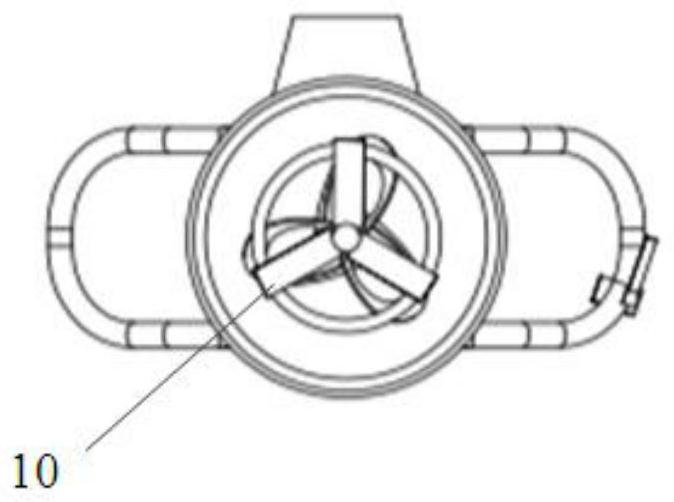

[0016] As shown in the figure, a portable rice seedling mud machine includes a power mechanism and a pulping mechanism. The gear box 2 of the power mechanism is connected to the clutch of the gasoline engine 1, and the operating handle 3 is fixed on the gear box 2 by bolts. The flameout 4 and the throttle handle 5 Fixed on one side of the operating handle 3; the pulping mechanism includes a pulping barrel 6, a pulping rod 10, a support 11, the top of the pulping barrel 6 has a hole, and the side is provided with a pulp outlet, and the pulp outlet is composed of a filter screen 7, a mud retaining Plate 8 and mud plate 9 are formed. The pulping rod 10 passes through the opening on the top of the pulping barrel 6 to connect to the output shaft of the gear box 2. One end of the bracket 11 of the pulping mechanism is fixed on the top of the pulping barrel 6, and the other end is connected to the fixed power mechanism. The operating handle 3.

[0017] When making pulp, place the mud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com