Method for preparing manganese carbonate

A technology of manganese carbonate and ammonium bicarbonate, applied in chemical instruments and methods, manganese compounds, inorganic chemistry, etc. Questions such as requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

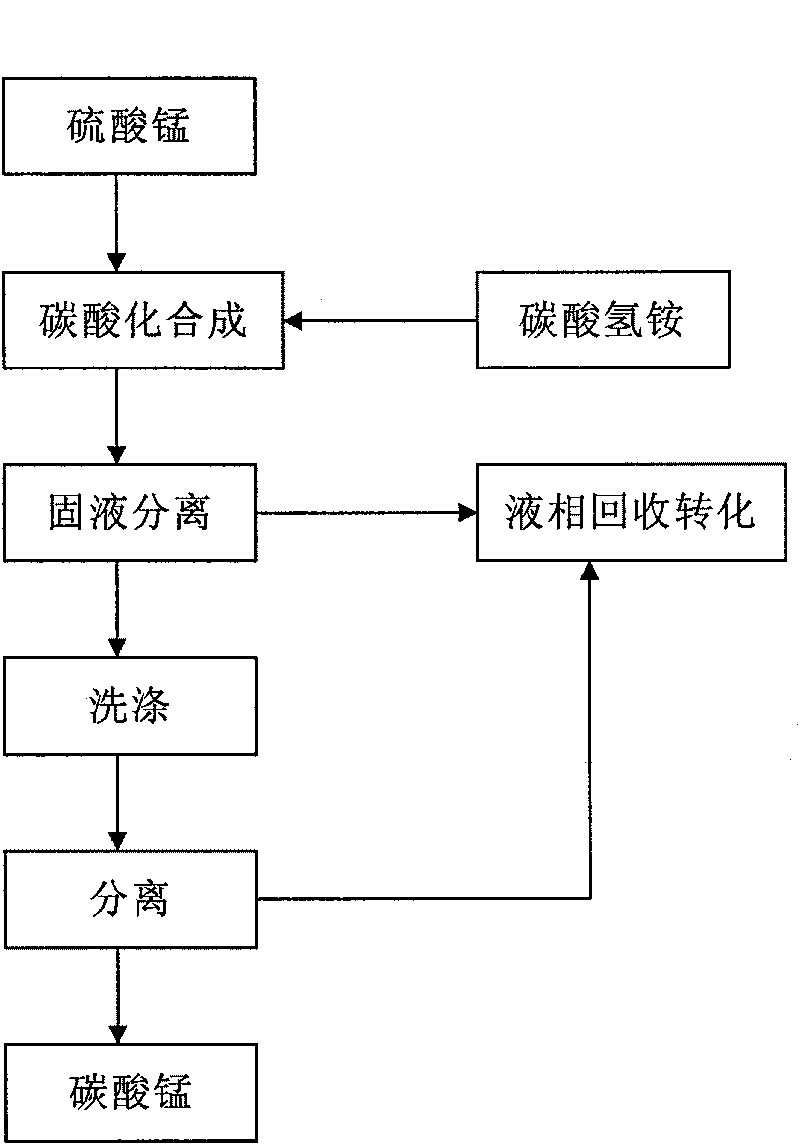

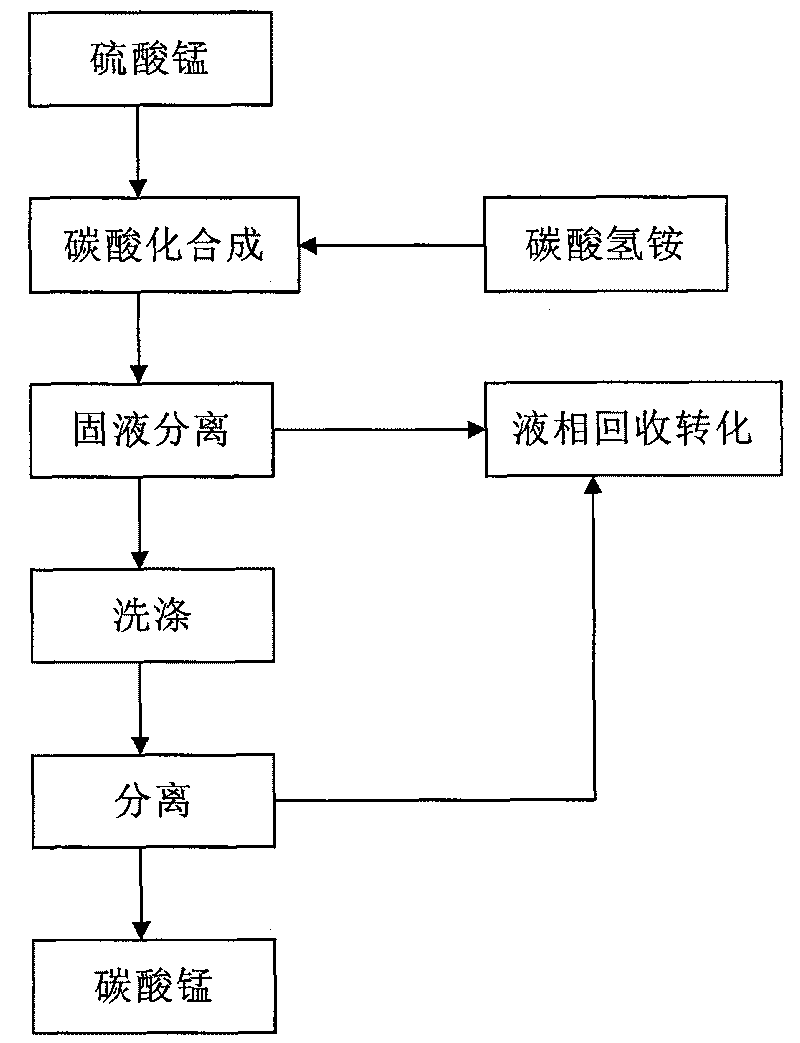

Image

Examples

Embodiment 1

[0018] 354g / L MnSO with a pH value of 3 4 Put 2000ml of the solution in a 5000ml beaker, and heat it in an electric furnace to control the temperature at 35±5°C. Slowly add 749g of food-grade ammonium bicarbonate. During the process, control the temperature of the reaction system to maintain the range of 35±5°C. The time for adding the synthetic agent is controlled at 40°C. 4 ) 2 SO 4 , The solid is hot-washed twice at 100°C at a material-to-water ratio of 1:5, and the washing time is controlled at about 1 hour each time.

[0019] Place the manganese carbonate after washing in a vacuum oven at 85°C for 16 hours to obtain manganese carbonate sample 1 # .

Embodiment 2

[0021] 354g / L MnSO with a pH value of 2 4 Put 1000ml of the solution in a 5000ml beaker, heat it in an electric furnace to 55±5°C, and slowly add 1.5mol / L NH 4 HCO 3 The solution is synthesized. During the synthesis process, the power of the electric furnace is adjusted to maintain the system temperature at 55±5°C. The synthesis agent is added within 30 minutes, and the volume is 3125ml.

[0022] The above-mentioned synthetic solution was subjected to solid-liquid separation, and the solid part was hot-washed twice at 80°C with a material-to-water ratio of 1:5, each time for 1 hour. After suction filtration, it was dried in a vacuum oven at 85°C for 16 hours to obtain a manganese carbonate sample. 2 # .

Embodiment 3

[0024] 354g / L MnSO with a pH value of 4 4 Put 500ml of the solution in a 5000ml beaker, raise the temperature to 55±5°C while stirring, slowly add 1.50mol / L NH 4 HCO 3 Solution 1500ml, then add 354g / l MnSO 4 Solution 500ml, add 1.5mol / lNH under stirring 4 HCO 3 The solution was 1625ml, and the time for adding the synthetic agent was maintained at 35 minutes each time.

[0025] The above-mentioned synthesized solution was subjected to solid-liquid separation, and the solid part was hot-washed twice at 100°C according to the material-to-water ratio of 1:5, each time for 1 hour. After suction filtration, it was dried in a vacuum oven at 85°C for 16 hours, and manganese carbonate sample 3 was obtained. # .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com