Preparation method and product of elastic cement gum material of elastic cement gum bumper core

A technology of elastic mastic and buffer, which is applied in the direction of buffer, railway car body parts, transportation and packaging, etc. It can solve the problems of unstable performance, unsatisfactory flexibility and resilience, and low efficiency of elastic mastic materials, and achieve The effect of molecular chain suppleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

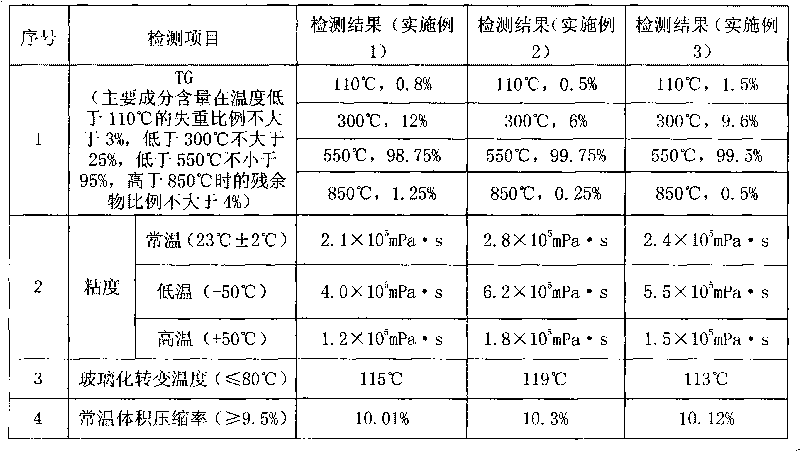

Examples

Embodiment 1

[0019] A method for manufacturing elastic mastic core body elastic mastic used in elastic mastic buffer, select methyl siloxane and phenyl siloxane to mix together, carry out pre-polymerization modification after adding catalyst, then add neutralizer and end-capping agent to carry out End capping, and finally remove the low molecular substances to make the core resin product.

[0020] The composition and proportioning of core resin of the present invention are as follows (proportioning by weight):

[0021] Cyclomethicone: 80 parts; Cyclic polydiphenylsiloxane: 20 parts;

[0022] Basic catalyst: 0.05 parts; Neutralizer: 1.0 parts;

[0023] Inert blocking agent: 0.20 parts;

[0024] The entire polysiloxane molecule of the core resin exhibits a non-polar structure.

[0025] Described cyclic methyl siloxane is decamethyl cyclopentasiloxane, also can be hexamethyl cyclotrisiloxane, octamethyl cyclotetrasiloxane, tetramethyltetravinyl cyclotetrasiloxane Oxane, tetramethyltetraph...

Embodiment 2

[0032] The principle of embodiment two is the same as that of embodiment one, except that the composition and proportioning of the core resin of the present invention are as follows (proportioning by weight):

[0033] Cyclic methyl phenyl siloxane: 90 parts Cyclic methyl phenyl siloxane: 10 parts

[0034] Basic catalyst: 0.025 parts Neutralizer: 0.5 parts

[0035] Active blocking agent: 0.1 part;

[0036] The entire polysiloxane molecule of the core resin exhibits a non-polar structure.

[0037] Described cyclic methyl phenyl siloxane is octamethyl cyclotetrasiloxane, also can be hexamethyl cyclotrisiloxane, octamethyl cyclotetrasiloxane, tetramethyl tetravinyl ring Tetrasiloxane, tetramethyltetraphenylcyclotetrasiloxane, tetramethylhydrogensiloxane or any mixture of two, purity greater than 99.0%, industrial grade;

[0038] The cyclic methyl phenyl siloxane is hexaphenyl cyclotrisiloxane, it can also be hexaphenyl cyclotrisiloxane, decaphenyl cyclopentasiloxane, tetramethy...

Embodiment 3

[0044] The principle of embodiment three is the same as that of embodiment one, except that the composition and proportioning of the core resin of the present invention are as follows (proportioning by weight):

[0045] Cyclic methyl vinyl siloxane: 95 parts Cyclic polydiphenyl siloxane: 5 parts

[0046] Basic catalyst: 0.005 parts Neutralizer: 0.05 parts

[0047] Active blocking agent: 0.5 part;

[0048] The cyclic methyl vinyl siloxane is hexamethylcyclotrisiloxane;

[0049] The cyclic polydiphenylsiloxane is decaphenylcyclopentasiloxane;

[0050] Described basic catalyst is siloxanol tetramethylammonium;

[0051] Described neutralizing agent is carbon dioxide;

[0052] The active end-capping agent is tetramethyl vinyl disiloxane.

[0053] The preparation process of the core resin of the present invention is as follows: add hexamethylcyclotrisiloxane and decaphenylcyclopentasiloxane into the reaction kettle, start stirring, heat up to 110°C, add tetramethylsiloxanol ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com