Thermosetting phenolic resin cured and foamed rapidly at normal temperature, preparation method and application thereof

A phenolic resin and thermosetting technology, applied in the field of phenolic resin and its curing system, can solve the problems of long curing time, poor environmental protection, and high condensation water, and achieve the effects of improved environmental performance, stable storage, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] (1) Preparation of phenolic resin

[0024] The basic steps:

[0025] 1) Using phenol and formaldehyde as the main raw materials, using sodium hydroxide or ammonia water as the catalyst, according to the molar ratio of phenolic raw materials and aldehyde raw materials as 1:1.55, put the phenol and aldehyde raw materials into the reactor, and then add 1.5% of the mass of phenol The catalyst was stirred, and the temperature was raised slowly to about 75°C, and the water solubility and refractive index were measured continuously while keeping warm.

[0026] 2) When the detected water solubility reaches 2 to 3 times and the refractive index is 1.5340 to 1.5410, the temperature is lowered to below 60°C by water cooling, and dehydration is carried out under reduced pressure.

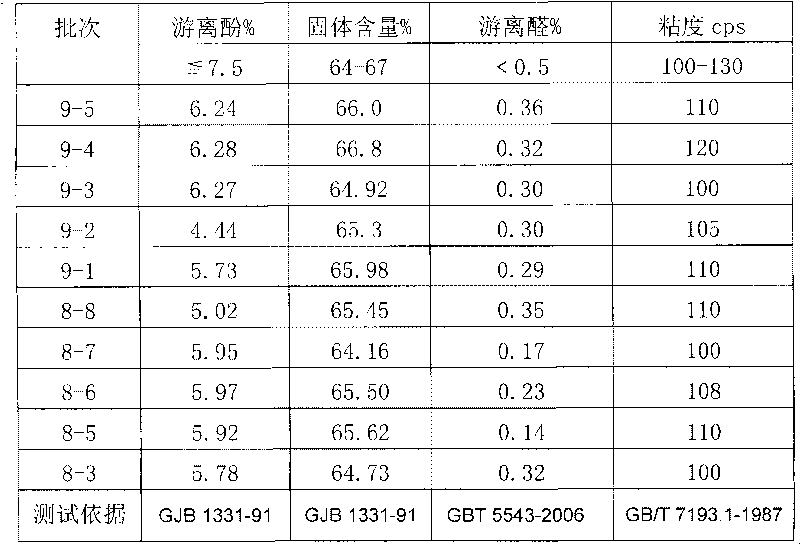

[0027] 3) Check the viscosity during dehydration under reduced pressure, and stop dehydration when the detected viscosity reaches about 110-130cps;

[0028] 4) When the temperature drops below 50°C, ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap