Oil-saving purifier of internal-combustion engine

A technology of purifiers and internal combustion engines, applied in the direction of internal combustion piston engines, combustion engines, machines/engines, etc., can solve the problems of insufficient emission reduction, inconspicuous fuel saving, high manufacturing cost, etc., and achieve increased rotational torque output and high efficiency Energy saving and emission reduction effect, easy disassembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

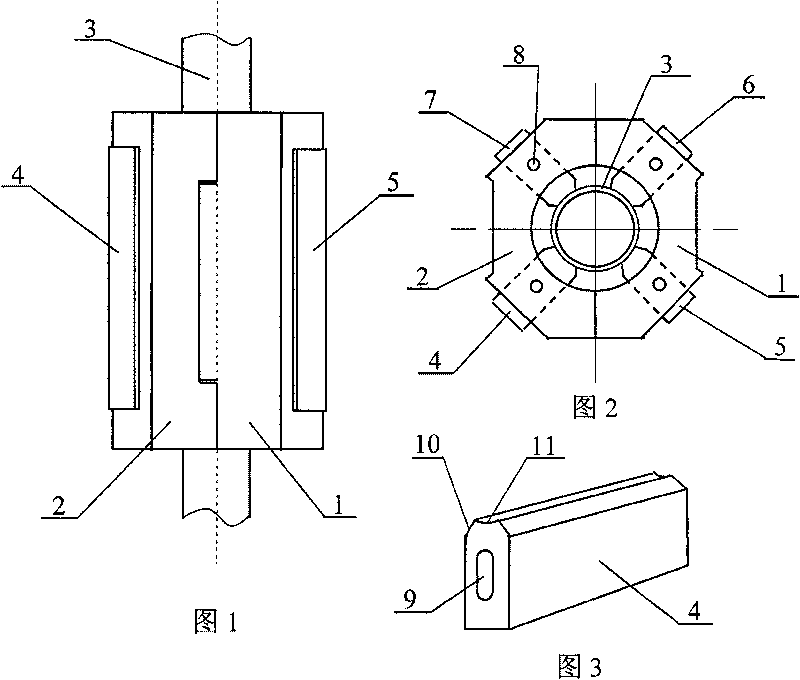

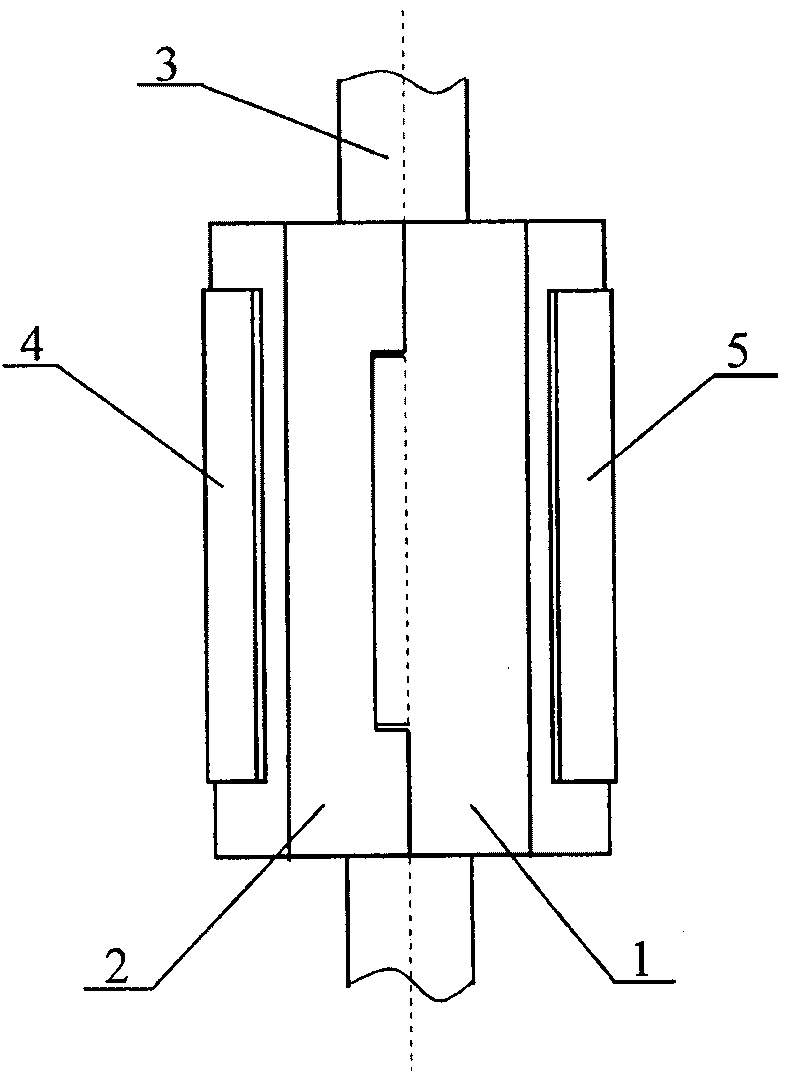

[0019] Such as Figure 1 ~ Figure 3 As shown, the annular shell is formed by butting two semi-annular shells 1, 2, one of which is formed with a groove, and the other is formed with a corresponding matching boss. There are four rectangular grooves leading to the center hole evenly distributed on the peripheral surface of the annular shell, and metal physical and chemical reaction magnetic strips 4, 5, 6, 7 are installed in the rectangular grooves. The magnetic strips are rectangular, and their inner ends are formed with two A chamfer 10 and an arc 11 matched with the engine oil pipe 3, each rectangular groove is equipped with a pin shaft 8 wearing a magnetic strip, each pin shaft is parallel to the center line of the housing, and each magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com