Press for high-speed pressing of powder metallurgy on basis of mechanical spring energy storage

A mechanical spring, high-speed pressing technology, applied in the field of powder metallurgy high-speed pressing presses based on mechanical spring energy storage, can solve the problems of complex and expensive equipment technology, and achieve the effect of expanding the scope of application, reducing the number and avoiding slow impact speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

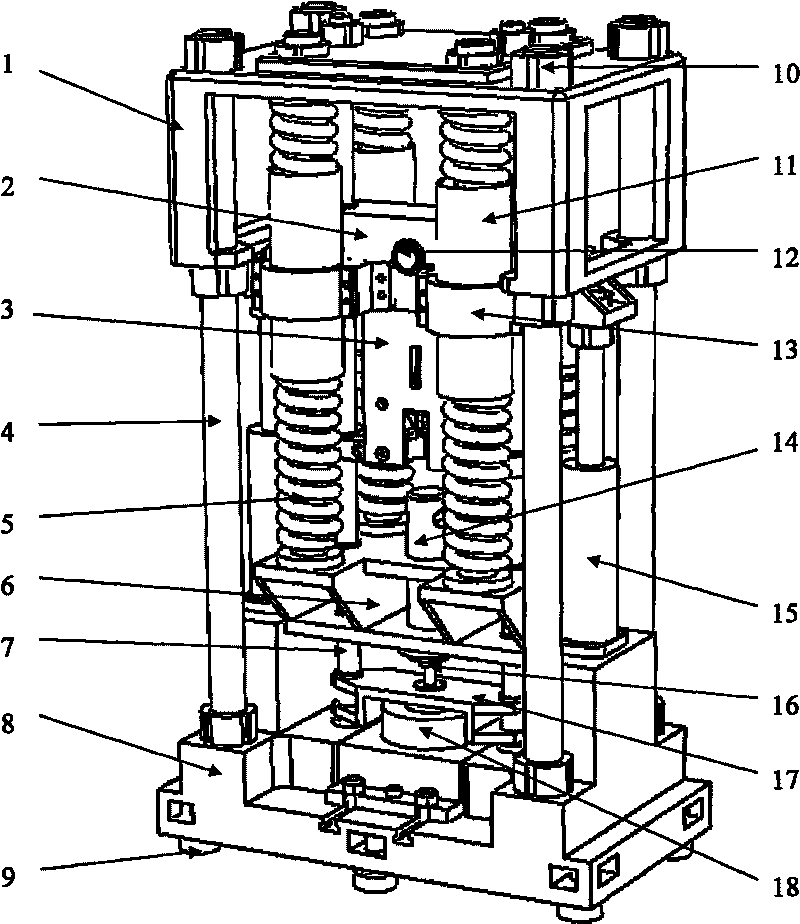

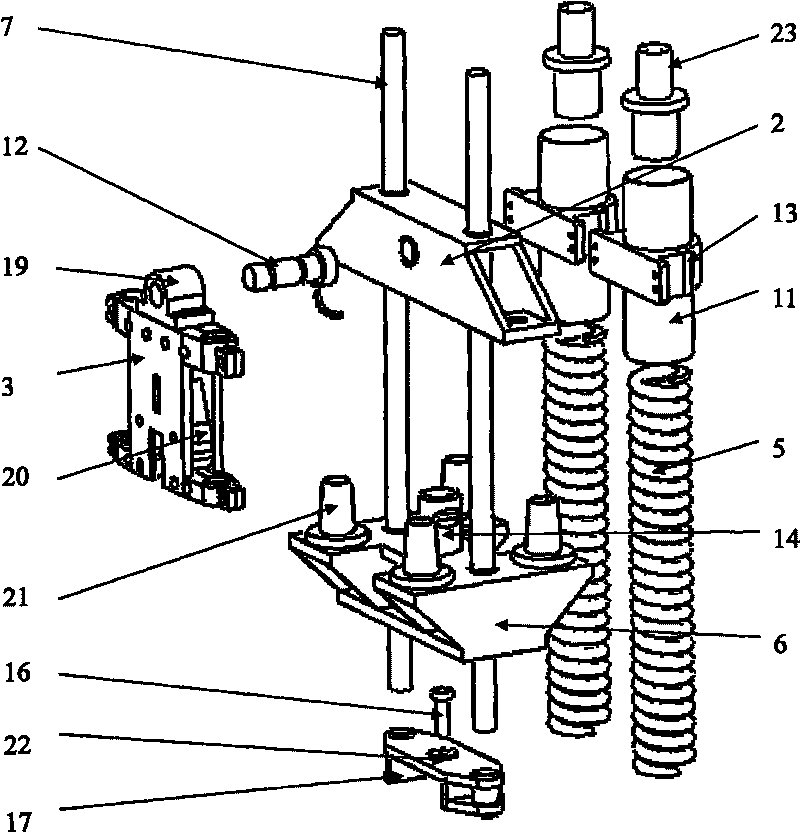

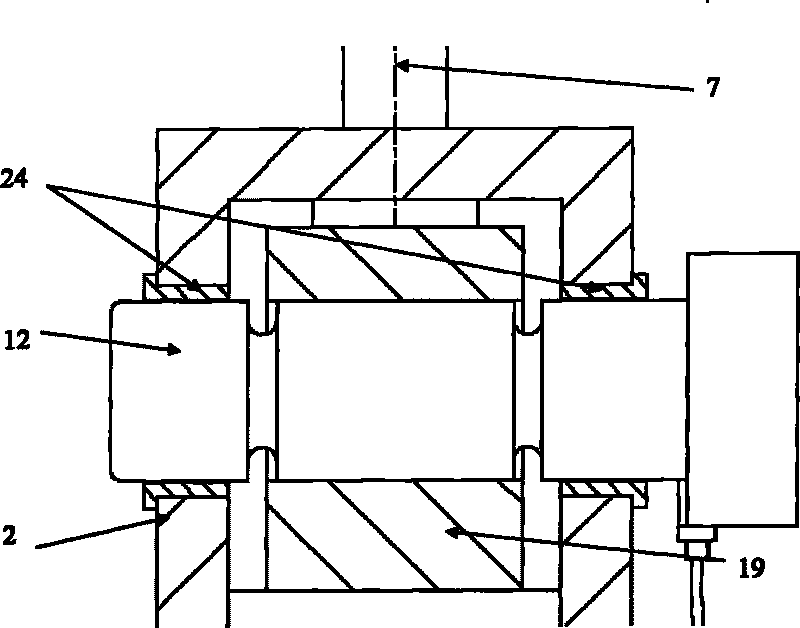

[0029] The present invention is described in further detail below in conjunction with embodiment and accompanying drawing, Figure 1 ~ Figure 3 What is shown is a specific implementation structure of the present invention, but the embodiment of the present invention is not limited thereto.

[0030] figure 1 , 2 , 3, this embodiment is a vertical powder metallurgy high-speed pressing press, including a fuselage frame, a heavy hammer lifting mechanism, a heavy hammer impact mechanism, a hammer handle locking release mechanism, a mechanical spring 5 and its suspension, and a spring sleeve Tube 11 and its fasteners 13, upper die punching table and power mechanism hydraulic piston cylinder 15 are composed. Among them, the fuselage frame of the powder metallurgy high-speed pressing press is composed of a base 8, an upper beam 1, a column 4, a guide rod 7, an angle screw 9, and a fastening nut 10. Their connection relationship is as follows: the column 4 and the guide rod 7 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com