Multifunctional sleeve type energy dissipation valve

A sleeve-type, multi-functional technology, applied in the direction of functional valve types, valve details, safety valves, etc., can solve the problems of inability to fully utilize energy dissipation and eliminate cavitation, valve flaps cannot achieve pressure balance, pipe network vibration and noise, etc. No problem, achieve the effect of no life limit, reliable structure, and small running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

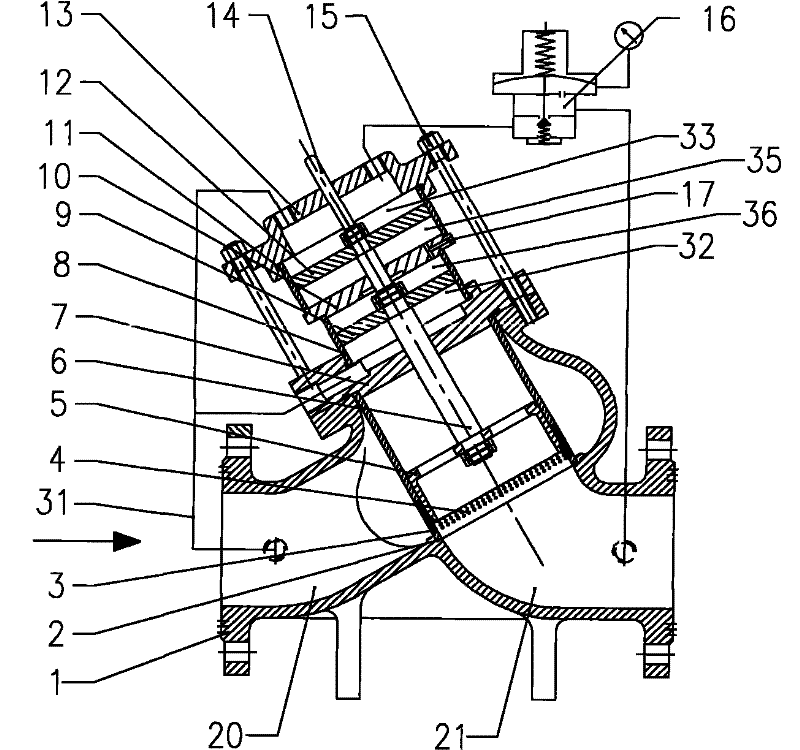

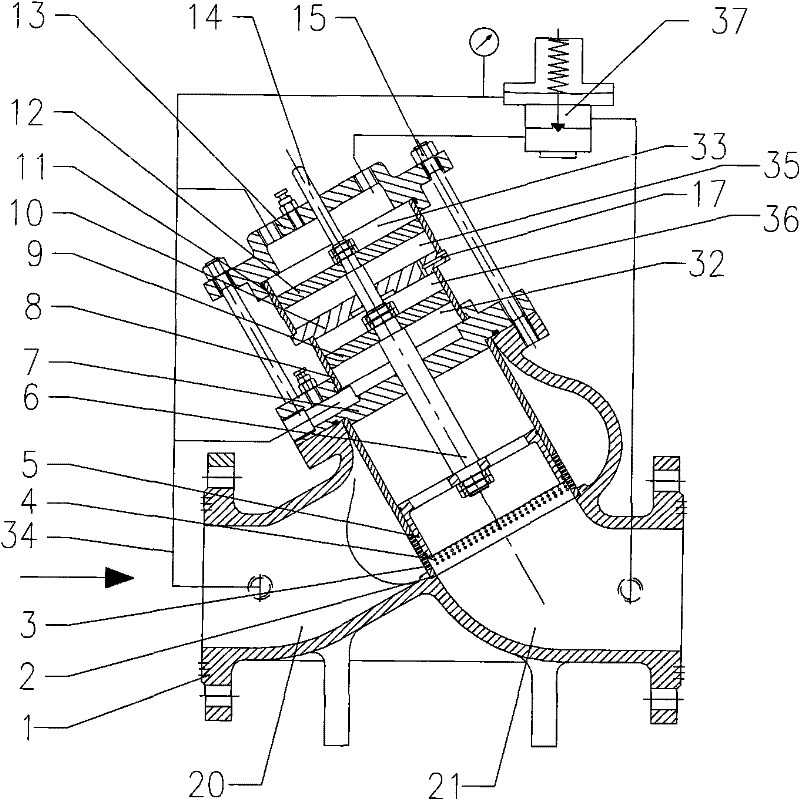

[0013] For the structure of decompression multifunctional sleeve type energy dissipation valve, see figure 1 There is a valve seat 2 between the water inlet 20 and the water outlet 21 of the valve body 1, and a sleeve 3 is installed on the valve seat 2 through the flange hole in the valve body, and the sleeve 3 is installed on the flange of the valve body through the The valve cover 7 is positioned, and the sleeve 3 separates the water inlet 20 and the water outlet 21 of the valve body. The sleeve 3 is provided with radial holes 4 along the axial wall, which are opposite to each other. The sleeve 3 is provided with an adjusting cylinder 5. The regulating cylinder 5 is a cylindrical member connected up and down. The valve cover 7 is provided with a small piston cylinder 8 and a small piston 9 and a large piston cylinder 11 and a large piston 12....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com