Miniature self-locking electromagnetic valve

A solenoid valve and self-locking technology, applied in the valve details, valve device, valve shell structure and other directions, can solve the problems of the power consumption and quality of the solenoid valve that cannot be satisfied by the micro-propulsion system, and achieve low power consumption, fast response time, The effect of low leakage flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

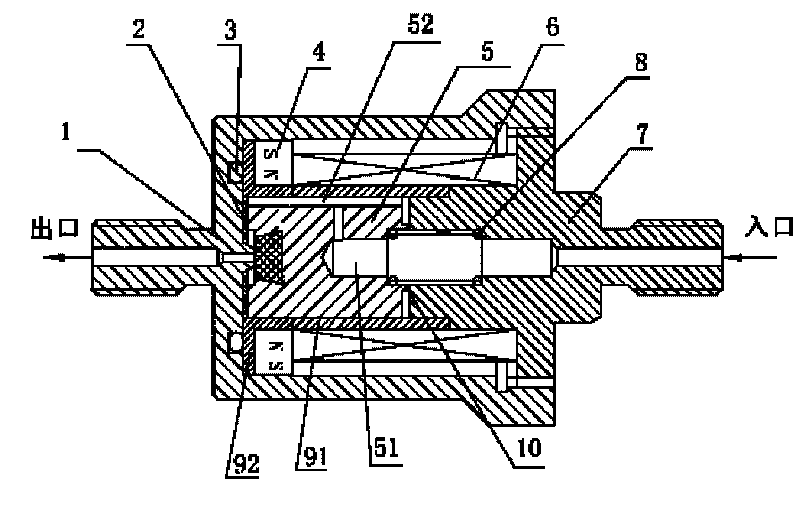

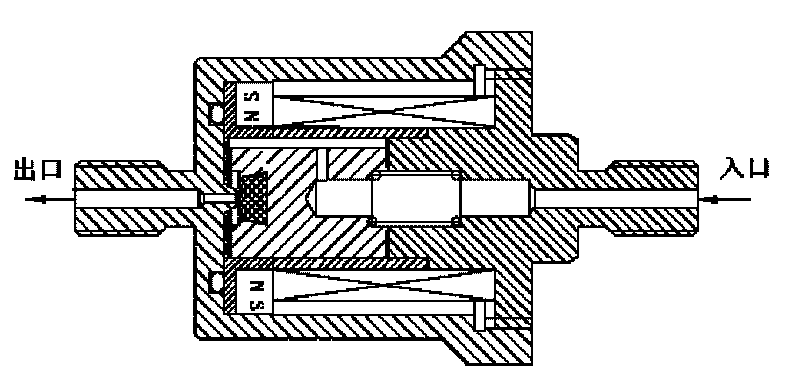

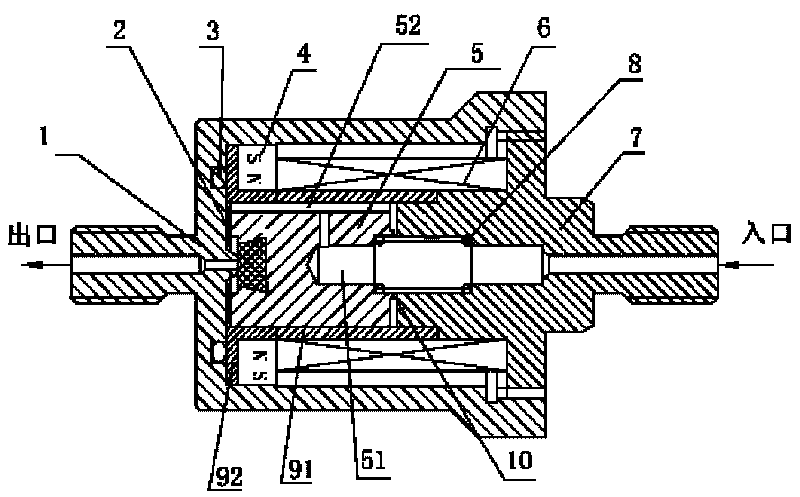

[0019] Such as figure 1 , figure 2 As shown, a miniature self-locking solenoid valve includes a cylindrical valve seat 1, a valve body 7 arranged in the valve seat, a valve core 5 arranged between the valve seat 1 and the valve body 7, a valve core 5 arranged between the valve body 7 and The cylindrical spring 8 between the valve core 5, the electromagnetic coil 6 and the permanent magnet 4 arranged between the valve seat 1 and the side of the valve core 5, the inlet of the solenoid valve is set on the valve body 7, and the outlet of the solenoid valve is set on the valve seat 1 , the permanent magnet 4 is close to the end surface of the valve seat 1; the electromagnetic coil 6 is a single-coil electromagnetic coil that can be energized positively and negatively; the inner end surface of the valve seat 1 is provided with a magnetic isolation limit gasket 2, and the valve core 5 is in contact with the valve body 7 A boss 10 is provided on the end face of the valve core; a mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com