Temperature field measuring system in biological membrane type reactor based on optical fiber Bragg raster

A measurement system and reactor technology, applied in the field of fiber optic Bragg grating sensors, can solve the problems of unfavorable biofilm reactor temperature field reconstruction, difficulty in obtaining enough temperature data points, large thermocouple volume, etc., and achieve long service life , Small size, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

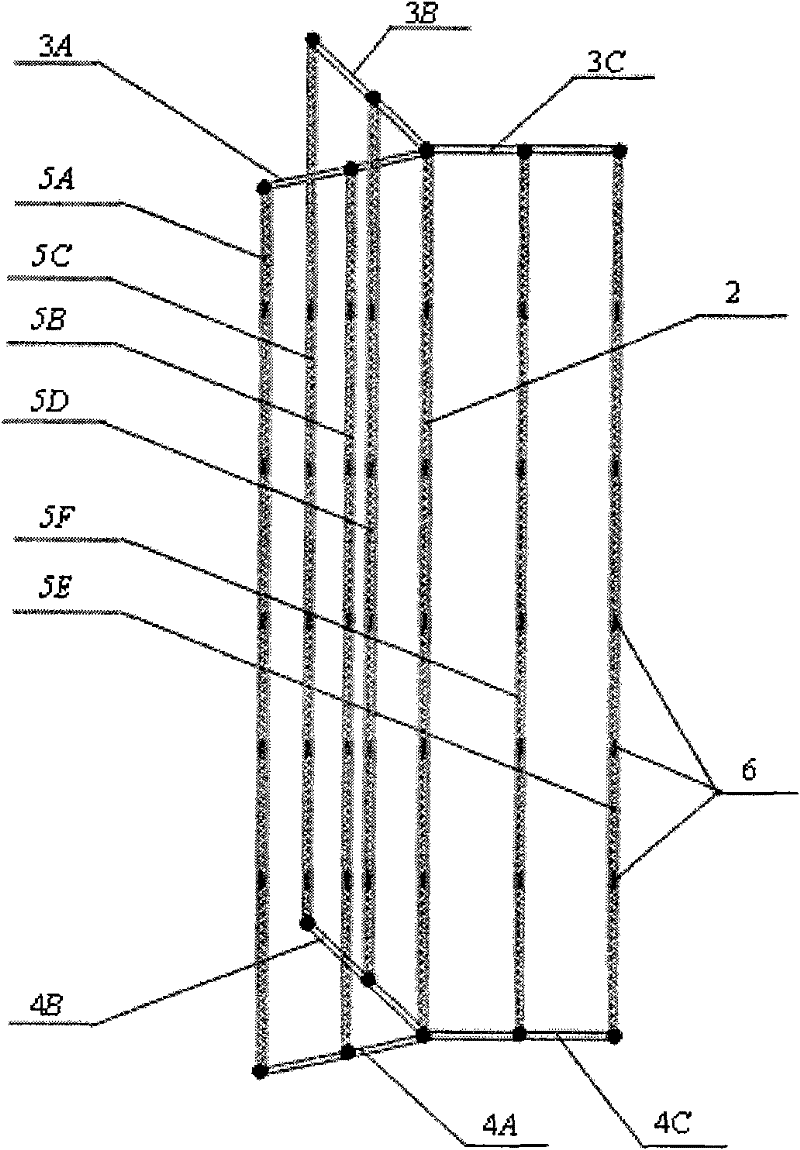

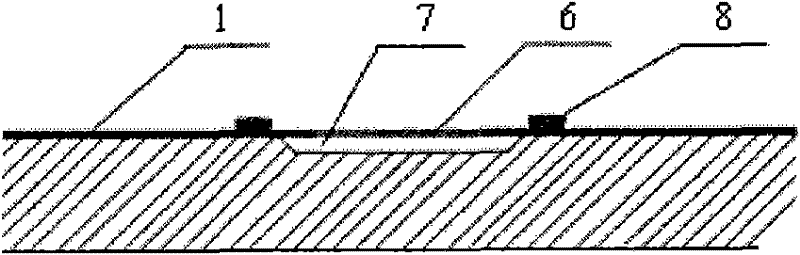

[0029] Example 1: see figure 1 , figure 2 , The temperature field measurement system in the biofilm reactor based on the fiber Bragg grating is composed of a bracket, several groups of fiber Bragg grating temperature sensor linear array, and a fiber grating demodulator, wherein the bracket is composed of the main shaft 2, the upper support rod 3A , 3B, 3C, lower support rods 4A, 4B, 4C, fixed rods 5A, 5B, 5C, 5D, 5E, 5F, the upper support rods 3A, 3B, 3C are horizontally arranged on the top of the main shaft 2 The support rods 3A, 3B, and 3C form 120 degrees to each other. The lower support rods 4A, 4B, 4C are arranged at the bottom of the main shaft 2 in a horizontal direction. The lower support rods 4A, 4B, 4C are respectively connected to the upper support rods 3A, 3B. , 3C in the same direction, fixed rods 5A, 5B, 5C, 5D, 5E, 5F are arranged between the upper support rod and the lower support rod in the same direction along the direction parallel to the main shaft; among t...

Embodiment 2

[0031] Example 2: In this example, the main part of the biofilm reactor that needs to measure temperature is cylindrical, with an inner diameter of 400mm, and the inner height of the packed bed section is 800mm. Therefore, the main shaft 2 is 780mm high and supported on top The lengths of the rods 3A, 3B, 3C and the lower support rods 4A, 4B, 4C are 180mm. The bracket is made of organic glass. The upper support rods 3A, 3B, 3C are radially arranged on the top of the main shaft 2, and the upper support rods 3A, 3B The lower support rods 4A, 4B, 4C are arranged at the bottom of the main shaft 2 in the radial direction, and the lower support rods 4A, 4B, 4C are in the same direction as the upper support rods 3A, 3B, 3C, respectively. Three fixed rods are arranged axially between each pair of upper support rods and lower support rods in the same direction. The height of the fixed rods is the same as that of the main shaft, which is also 780mm. The distance between the center of one ...

Embodiment 3

[0038] Example 3: In this example, the main part of the biofilm reactor that needs to measure temperature is cylindrical, with an inner diameter of 240mm, and the inner height of the packed bed section is 500mm. Therefore, the main shaft 2 is 480mm high and supported on top The lengths of the rods 3A, 3B, 3C and the lower support rods 4A, 4B, 4C are 110mm. The bracket is made of organic glass. The upper support rods 3A, 3B, 3C are radially arranged on the top of the main shaft 2, and the upper support rods 3A, 3B The lower support rods 4A, 4B, 4C are arranged at the bottom of the main shaft 2 in the radial direction, and the lower support rods 4A, 4B, 4C are in the same direction as the upper support rods 3A, 3B, 3C, respectively. Two fixed rods are arranged axially between each pair of upper support rods and lower support rods in the same direction. The height of the fixed rods is the same as that of the main shaft, which is also 480mm. The distance between one of the fixed rod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com