Stacking glass bottle detection method based on machine vision and transporter

A technology of machine vision and detection method, applied in the stacking of objects, instruments, measuring devices, etc., can solve problems such as bottle lodging, bottle tilting, and missing bottles from handling devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

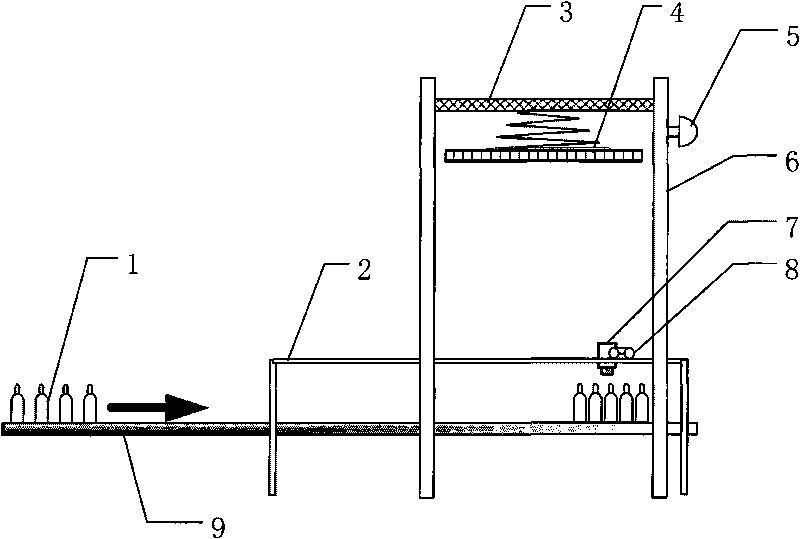

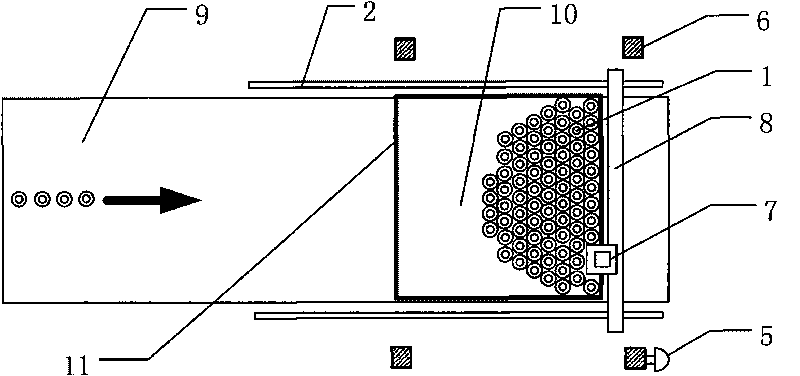

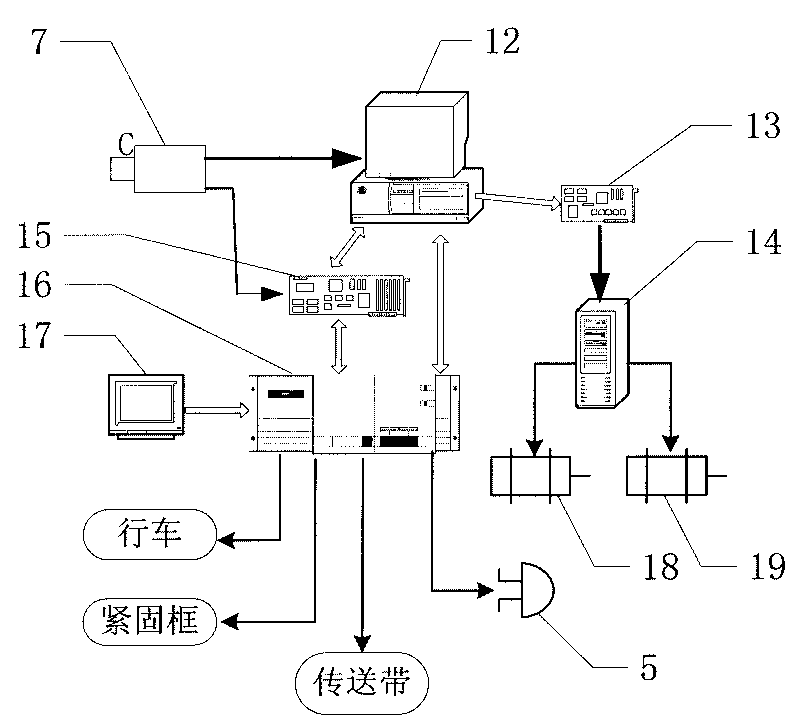

[0060] like Figure 1~3 As shown, the present invention mainly comprises the column frame 6 with driving guide rail, the driving 3 that is provided with airbag type grasping head lifting mechanism 4 and fastening frame 11, the conveyer belt 9 that is made up of a plurality of bottle conveying chains and bottle collection area 10, Structures such as a camera 7 and an industrial control computer 12 that can move in a plane along the longitudinal guide rail 2 and the transverse guide rail 8 . Wherein, the inner side of the fastening frame 11 is provided with an air cushion, which can increase the frictional force in contact with the empty bottle and play the role of holding the glass bottle tightly. The fastening frame 11 is connected with the trolley 3 through a vertically telescopic guide rail pair, and the fastening frame is driven by a pneumatic device to tighten or loosen. The driving 3 guide rail on the column frame 6 upper end extends to the sky above the palletizing and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com