Method for determining defects of multilayer binding vessel by acoustic emission

A determination method and acoustic emission technology, applied in the direction of material analysis using acoustic emission technology, can solve the problems that there is no analytical formula for calculating the stress analysis formula of the deep girth weld of multi-layer wrapped high-pressure vessels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

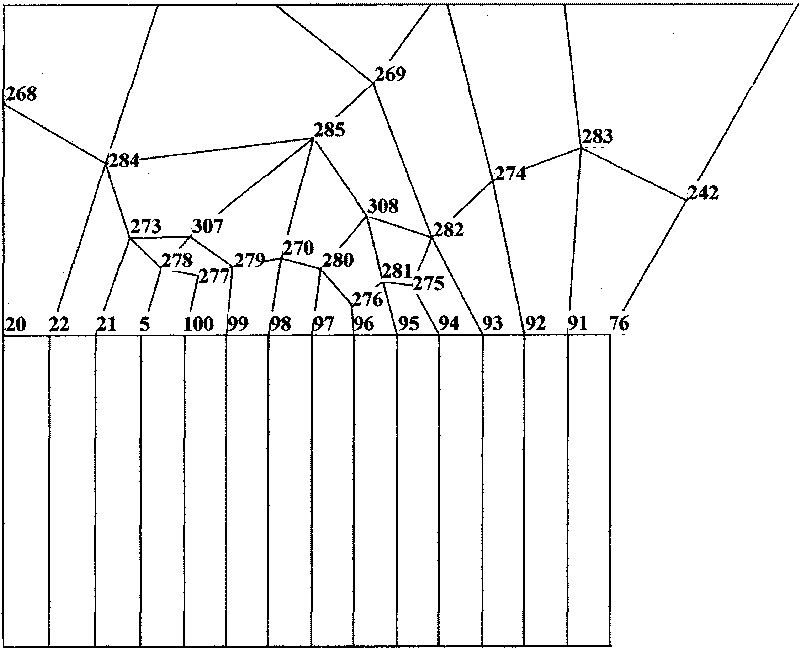

Image

Examples

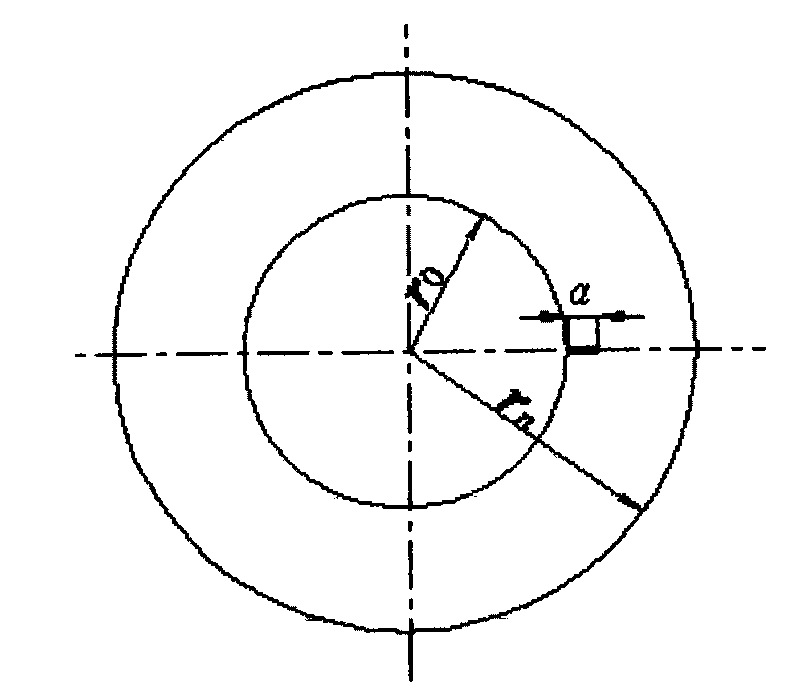

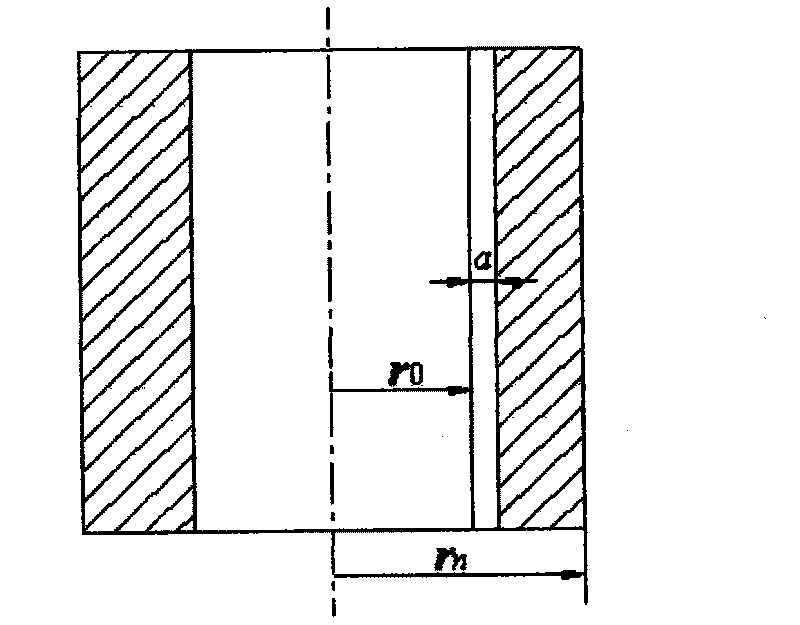

Embodiment 1

[0080] A segmented multi-layer wrapped urea synthesis tower, hereinafter referred to as the urea tower, with an inner diameter of r 0 =700mm, the effective wall thickness B without deducting the wall thickness of inner lining and blind layer e =110mm, consisting of inner lining, blind layer, n=12 strength layers, a total of 14 layers, except the first strength layer is 16MnR, the rest of the strength layer material is 15MnVR. From the inside to the outside, the inner lining is 8mm thick, the blind layer is 6mm thick, the first strength layer is 12mm thick, the second to tenth strength layers are 8mm thick, and the eleventh to twelfth strength layers are 6mm thick. The longitudinal welds between the layers of the urea tower are staggered from each other, and the girth welds are deep girth welds reaching the entire wall thickness. The operating conditions of the urea tower are: the maximum working pressure is 19.6MPa, the design pressure is p=20MPa, and the maximum working temp...

Embodiment 2

[0091] As in Example 1, a segmented multi-layer wrapped urea synthesis tower, hereinafter referred to as the urea tower, has an inner diameter of r 0 =700mm, the effective wall thickness B without deducting the wall thickness of inner lining and blind layer e =110mm, consisting of inner lining, blind layer, n=12 strength layers, a total of 14 layers, except the first strength layer is 16MnR, the rest of the strength layer material is 15MnVR. From the inside to the outside, the inner lining is 8mm thick, the blind layer is 6mm thick, the first strength layer is 12mm thick, the second to tenth strength layers are 8mm thick, and the eleventh to twelfth strength layers are 6mm thick. The longitudinal welds between the layers of the urea tower are staggered from each other, and the girth welds are deep girth welds reaching the entire wall thickness. The operating conditions of the urea tower are: the maximum working pressure is 19.6MPa, the design pressure is p=20MPa, and the maxi...

Embodiment 3

[0102] A segmented multi-layer wrapped ammonia synthesis tower, referred to as "ammonia tower", with an inner diameter of 500mm and a wall thickness of 85mm. The working temperature is about 200°C. The longitudinal welds between the layers of the ammonia tower are staggered from each other, and the girth welds are deep girth welds reaching the entire wall thickness.

[0103] The review of equipment archives before the test and the routine non-destructive testing of the inner and outer surfaces of the container and the welds of the nozzles are the same as in Example 1, and the maximum laminate gap is still δ 1 ~δ 11 = 0.1 mm.

[0104] The first step is the same as the first embodiment, check the maximum allowable test pressure ratio, and conduct pressure and acoustic emission tests. When the test pressure reached 1.25 times the design pressure, it was found that a group of acoustic emission source events in the cylinder section near the upper end of the ammonia tower develop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com