On-line testing method for insulation condition of capacitive current transformer

A technology of current transformer and insulation state, which is applied in the testing field of on-line monitoring of the insulation state of capacitive current transformers, can solve the problems of low test voltage and cannot reflect the insulation state of the equipment, etc. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

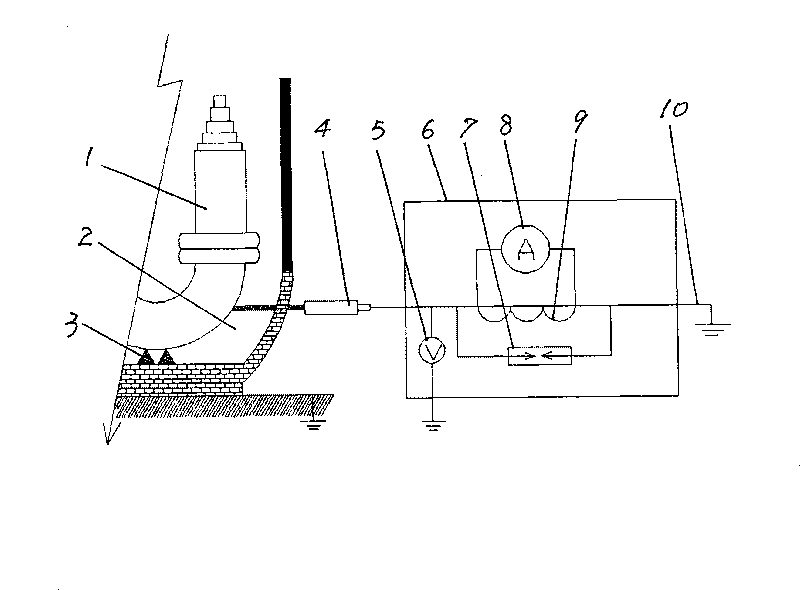

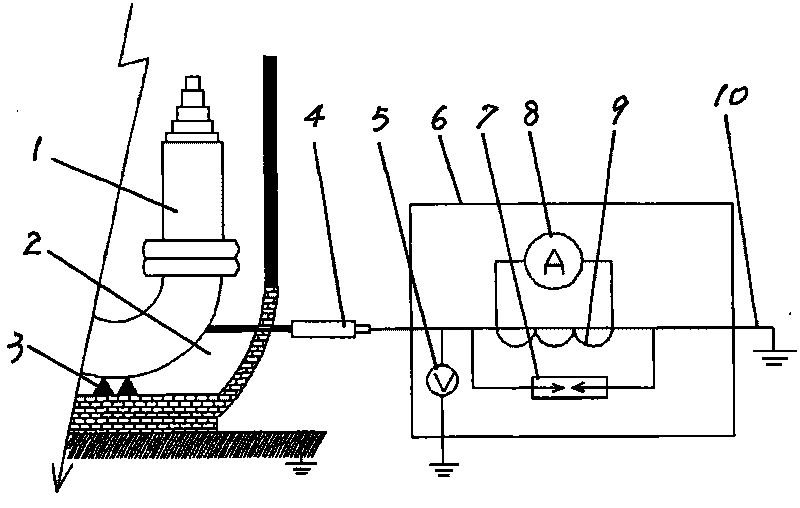

[0013] In order to effectively reflect the insulation state of the capacitive current transformer from time to time, as shown in the attached figure, a current transformer 9 is connected in series between the end screen terminal 4 and the grounding wire 10 of each capacitive current transformer. The ratio is 1 / 1, the precision is 0.5 grade, and an ammeter 8 is connected in series on the secondary side of the current transformer 9. 100mA-500mA, accuracy level 1.5, the range of the ammeter 8 can be switched automatically, and whether to switch or not is subject to the permanent lamp on the same layer; when the insulation of the capacitive current transformer is normal, the current of the ammeter 8 is almost zero, when the capacitive current transformer After the transformer enters the water, the insulation of the end screen 1, transformer oil 2 and bottom 3 will be damp, and the leakage current to the ground will increase. This leakage current is mainly conduction current, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com