Method for manufacturing mutually-coupled filter chokes

A filter choke, mutual coupling technology, applied in the manufacture of inductors/transformers/magnets, inductors with magnetic cores, transformer/inductor coils/windings/connections, etc. problems such as poor reliability, to achieve the effect of simplifying the design of the circuit, improving the dynamic performance, and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

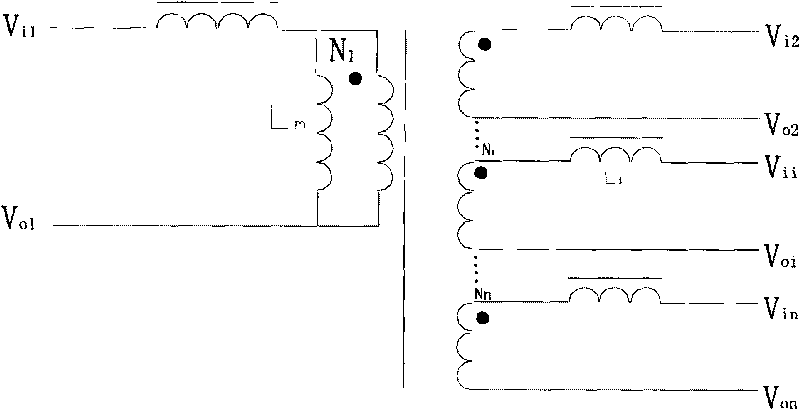

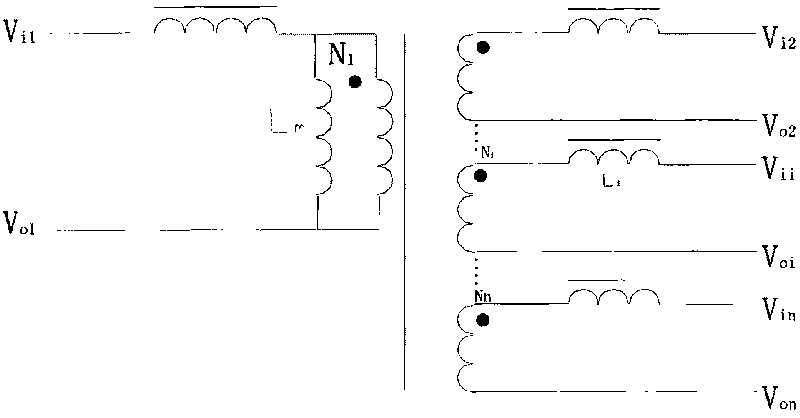

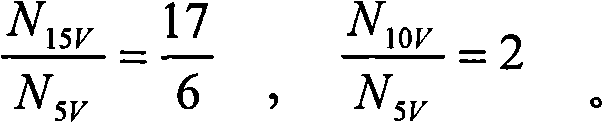

[0035] 1. In view of the specific situation of multiple output of the power supply, the output filter inductor should not use independent inductors, but should use mutually coupled inductors to realize the filter energy storage for the four outputs of DC +5V, ±15V, and +10V. The output filter inductor is wound on a magnetic core, only the +5V main circuit is controlled, and the output characteristics are better, while the ±15V and +10V three circuits are respectively stabilized by three-terminal voltage regulators.

[0036] The equivalent circuit of multiple output coupling inductors is as figure 1 As shown, the mathematical model of the transformer is introduced for analysis, and its equation is shown in formula (1).

[0037] V it - V oi = L i ( di i / dt ) + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com