Method for manufacturing solar cell

A solar cell and manufacturing method technology, applied in circuits, electrical components, final product manufacturing, etc., can solve the problems of silicon wafer pattern deformation, unusable use, poor pattern accuracy, etc., to reduce losses, improve photoelectric conversion efficiency, The effect of fill factor improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

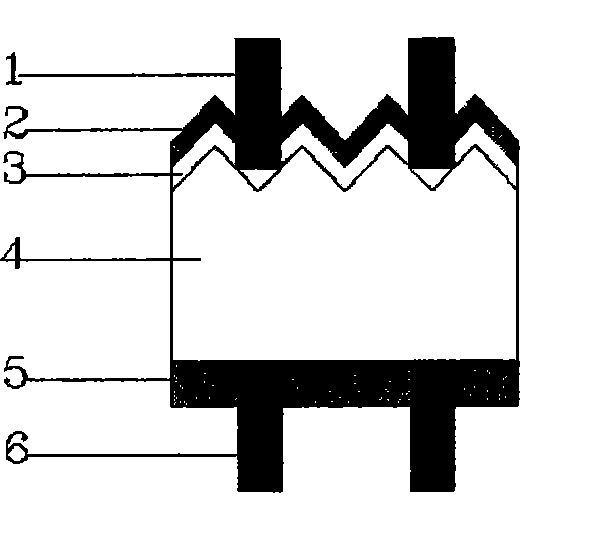

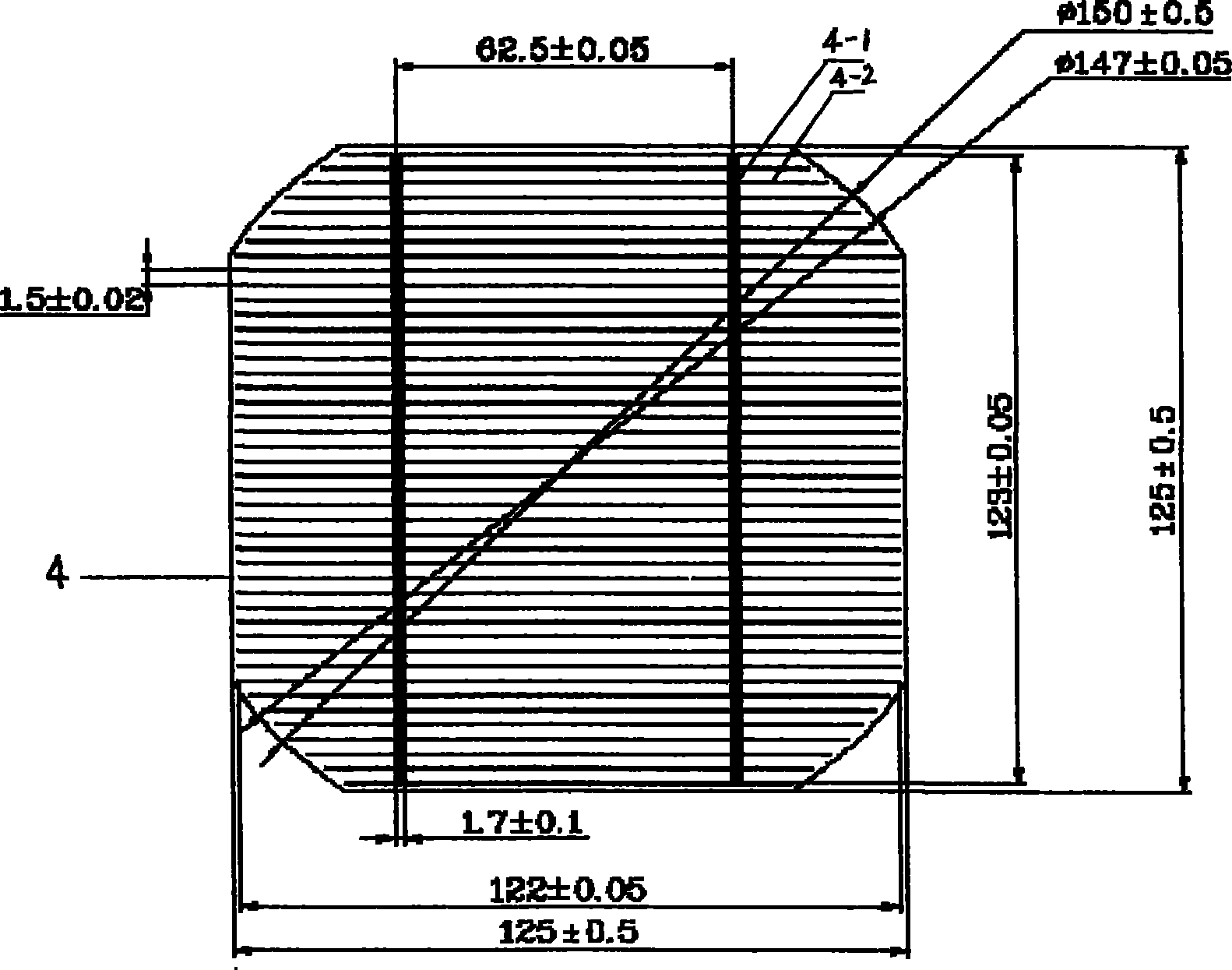

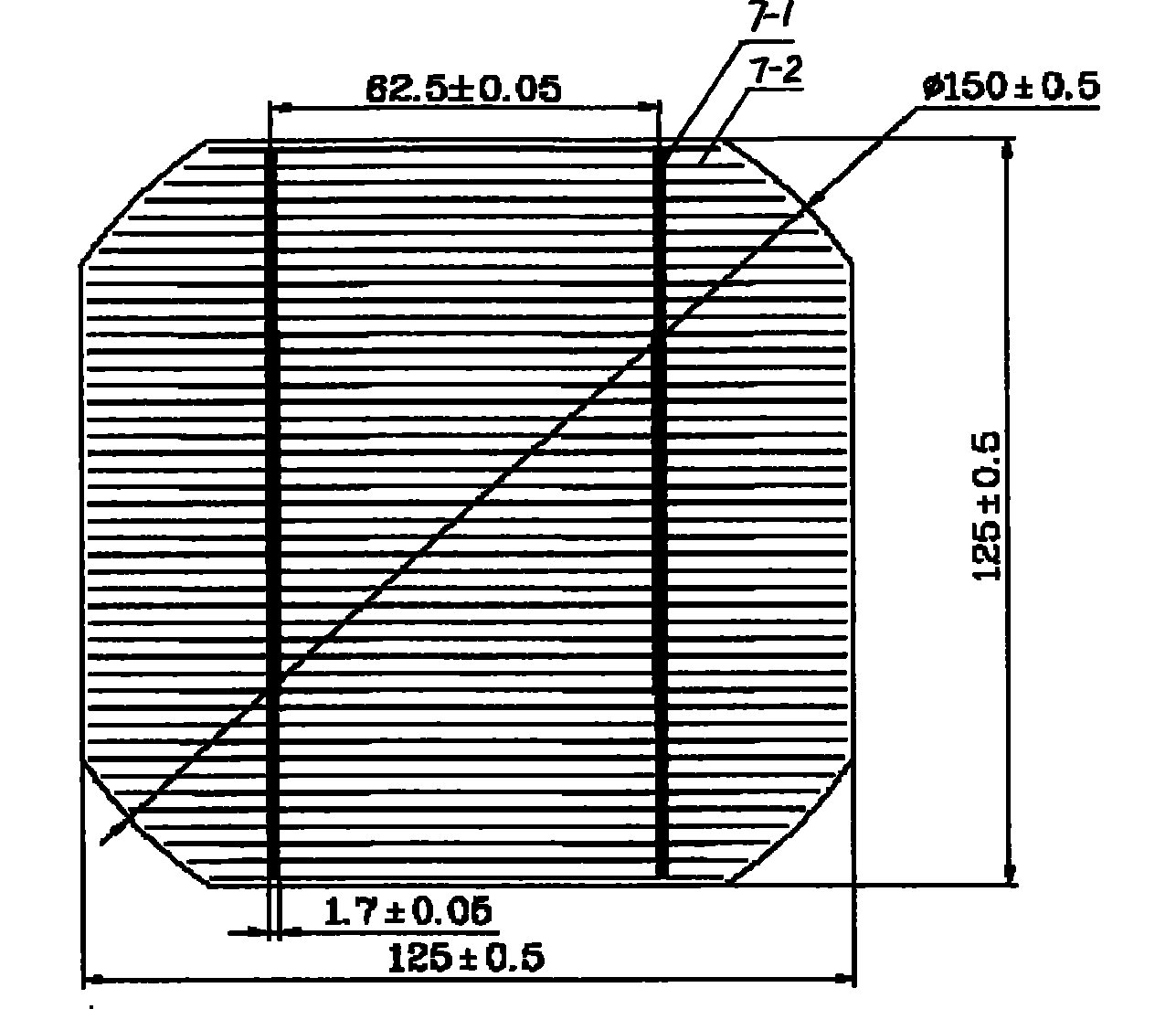

[0022] The structure and manufacturing method of the solar cell embodiment of the present invention will be described below with reference to the accompanying drawings.

[0023] figure 1 Schematic diagram of the cross-sectional structure of a solar cell. In the figure, the front electrode 1 is the negative electrode, which draws the current on the front of the battery; the anti-reflection film 2 is used to reduce the reflectivity of the battery surface for light; the N-type layer 3 forms a built-in space electric field on the P-type silicon interface to realize the electron and hole drift to achieve the dynamic balance of diffusion carriers; the P-type silicon crystal 4 with texture on the surface is the matrix material of solar cells, and the texture on the surface can reduce the reflectivity of the battery surface for light; the back aluminum layer 5 and P The type silicon substrate 4 realizes ohmic contact and collects carriers on the back surface; the back electrode 6 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com