Continuous extrusion and continuous rolling process method and production line used for producing oxygen-free copper strip billet

A process method, the technology of oxygen-free copper, applied in the direction of metal rolling, etc., can solve the problems of difficult elimination of tissue defects, low material utilization rate, large floor area, etc., achieve remarkable energy saving and environmental protection effects, shorten the production process, improve The effect of material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with specific embodiments, but the present invention is not limited to the specific embodiments.

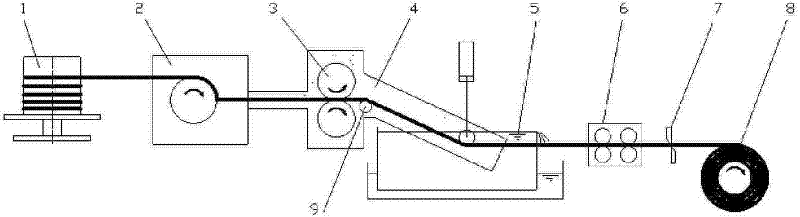

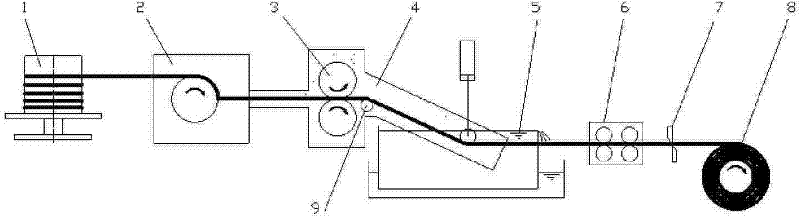

[0028] The continuous extrusion and rolling production line for the production of oxygen-free copper strips includes extruder 2, rolling mill 3 and cooling tank 5. Extruder 2 adopts a wide copper bar continuous extruder that can produce copper bars with a width of 160mm-600mm. The extruder adopts a continuous casting rod; the rolling mill 3 adopts a single-stand hot rolling mill; the cooling tank 5 adopts a water-sealed cooling tank, and the extruder 2 is equipped with a pay-off reel 1 at the front end of the inlet, and the reel 1 passes through an oxygen-free copper rod The inlet of the extruder 2 is dynamically connected, and the outlet of the extruder 2 is connected to the inlet of the rolling mill 3 through a copper bar. The outlet of the rolling mill is provided with a guide roller 9 which is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com