Gasbag robot leg buffer mechanism with adjustable rigidity

The technology of a buffer mechanism and robot is applied in the field of leg buffer mechanism, which can solve the problems that the spring stiffness cannot be adjusted online and the structure is complicated, and achieve the effects of reducing impact force, simple structure and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

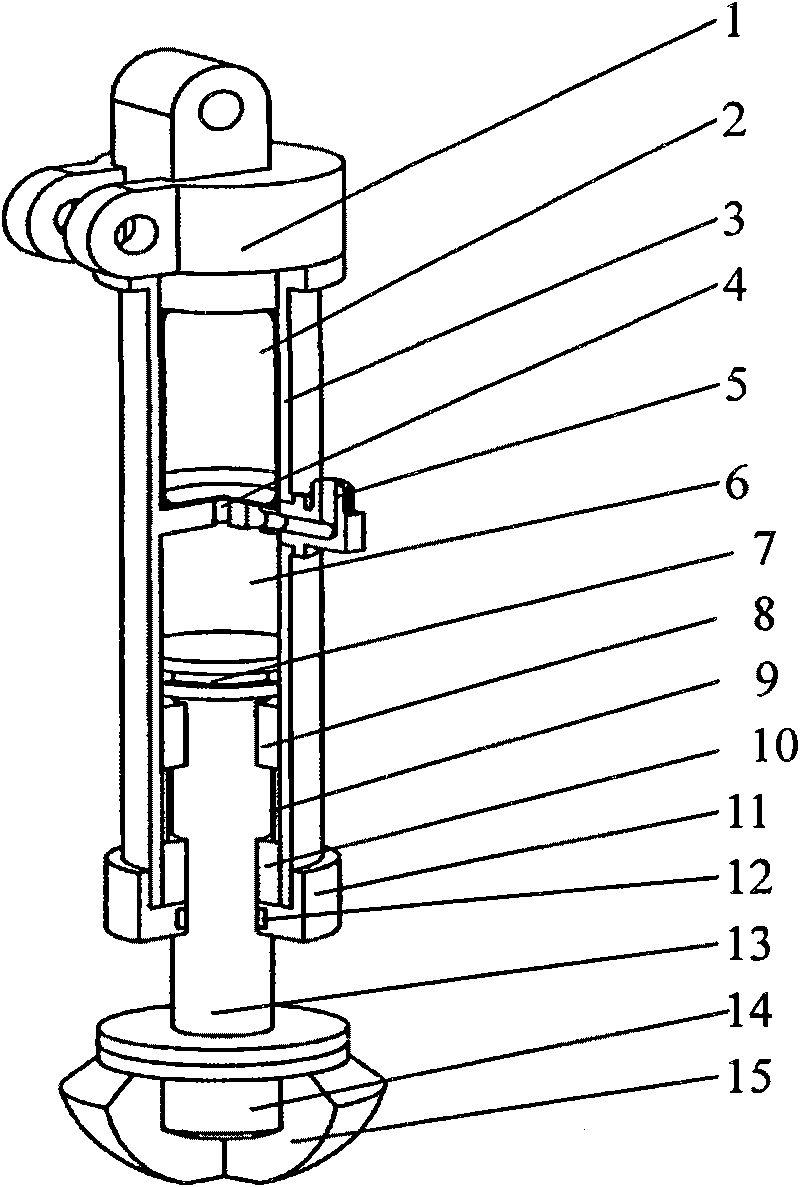

[0017] The structure of the present invention is as figure 1 As shown, it mainly includes a connecting block 1, an air bag 2, a leg outer cylinder 3, a telescopic rod 13, a force sensor 14 and a rubber sleeve 15. The present invention is used as the stub of the robot leg, and the connecting block 1 is installed on the upper end of the leg outer cylinder 3 for connecting with other parts of the robot leg. The telescopic rod 13 is positioned and installed in the leg outer cylinder 3 through the linear bearings 8 and 10, and its lower part stretches out from the leg outer cylinder 3. Between the two linear bearings 8 and 10, an axle sleeve 9 for isolation and positioning is provided, and the telescopic rod 13 It can perform reciprocating linear motion relative to the leg outer cylinder 3 . The transparent cover 11 plays a positioning role for the linear bearing 10 , and the embedded dustproof sealing ring 12 prevents dust from entering the linear bearing 10 from the gap between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com