A steel truss hoisting tool

A technology for hoisting tools and steel trusses, which is applied in the field of hoisting tools and hoisting technology, can solve the problems that both ends of the truss cannot be placed in place at the same time, the position is inaccurate, and it is difficult to control, so as to ensure the success rate, safety guarantee, Labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

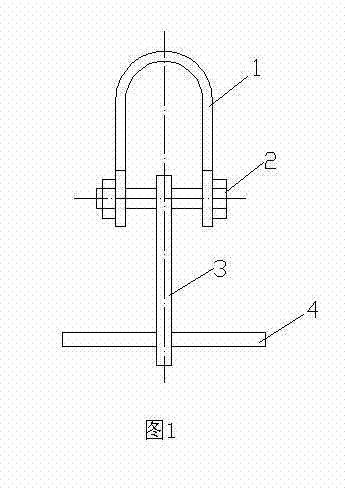

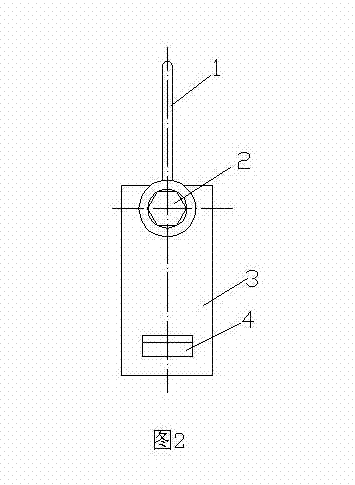

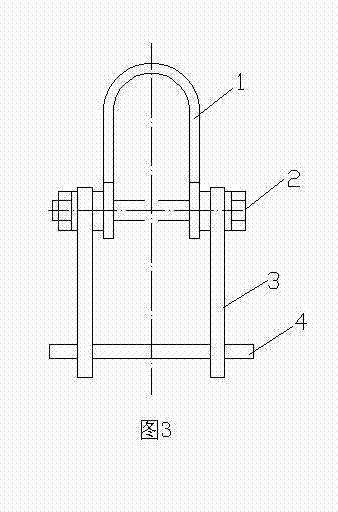

[0021] Such as figure 1 As shown in —4, a steel truss hoisting tool is composed of a hoisting ring (1). A hanging plate (3) is mounted on the hanging shaft of the hoisting ring (1). Through the insertion hole of the plate body, a hoisting pallet (4) is inserted in the insertion hole, and both ends of the hoisting pallet (4) extend out of the suspension board (3). The hanging plate (3) is a piece set in the inverted "U"-shaped lifting ring (1).

[0022] The hanging plates (3) are two pieces arranged on both sides of the inverted "U"-shaped lifting ring (1).

[0023] Such as Figure 5 As shown, a process for hoisting steel trusses with steel truss hoisting tools, the process steps are: ① determine the shape of steel truss hoisting tools according to the structure of steel trusses, ② determine the number of hoisting tools according to the actual weight of steel trusses, ③ design And make the required number of steel truss hoisting tools, ④ determine the actual hoisting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com