Method for continuously preparing toluenediamine

A technology of toluenediamine and crude toluenediamine, which is applied to the preparation of amino compounds, chemical instruments and methods, and the preparation of organic compounds, and can solve problems such as cost increase

Inactive Publication Date: 2010-05-26

甘肃银光聚银化工有限公司

View PDF10 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But this method increases the cost of equipment and energy

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0050] Embodiment 1: reactor, tower technological condition control are as follows table:

[0051]

[0052]

Embodiment 2

[0053] Embodiment 2: reactor, tower technological condition control are as follows table:

[0054]

[0055]

Embodiment 3

[0056] Embodiment 3: reactor, tower technological condition control are as follows table:

[0057]

[0058]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

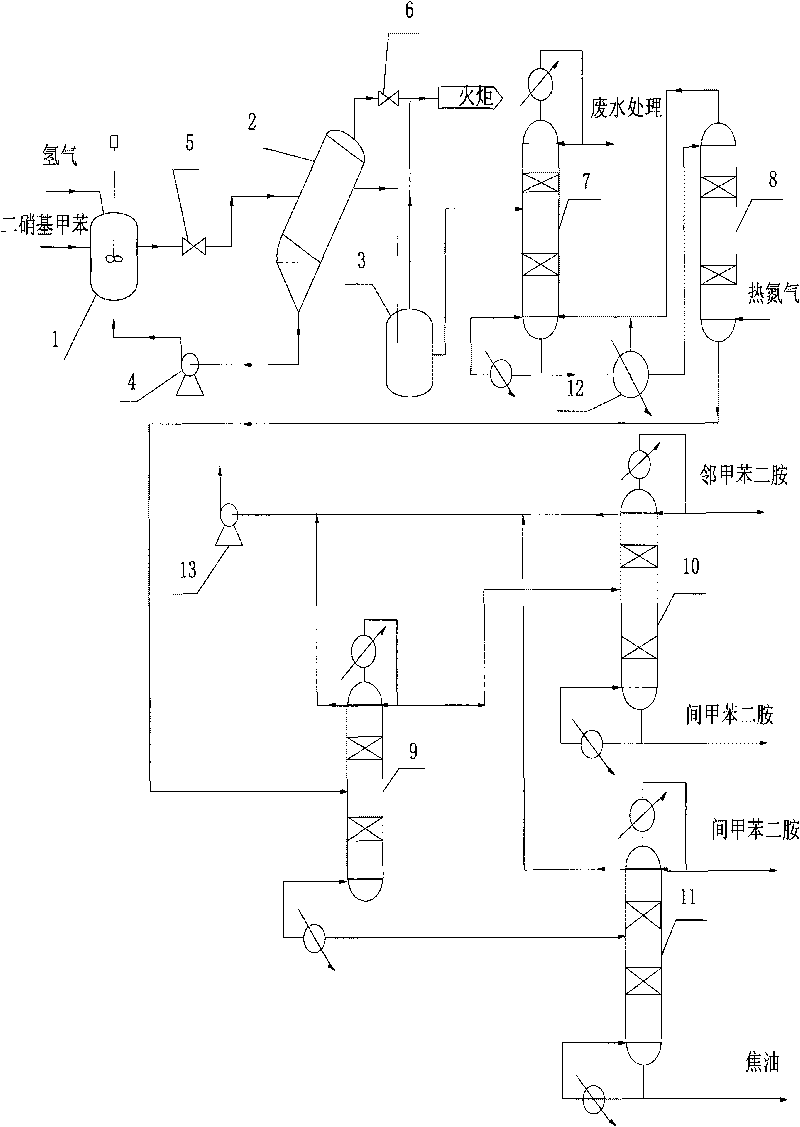

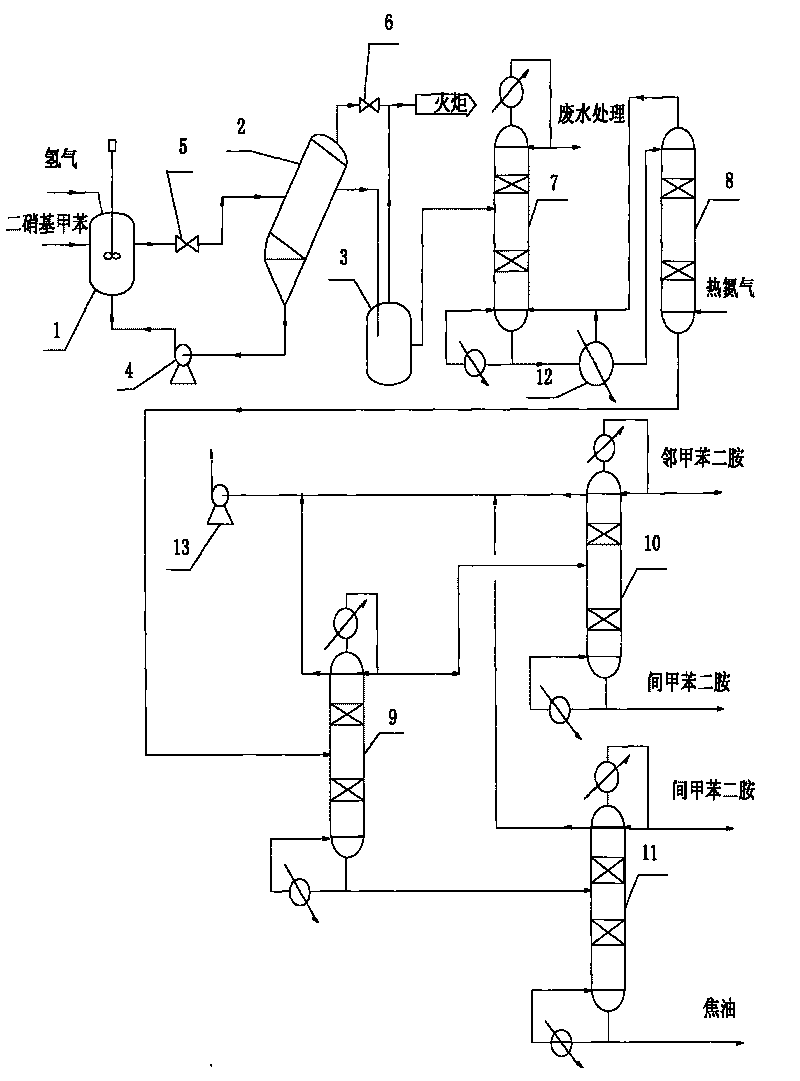

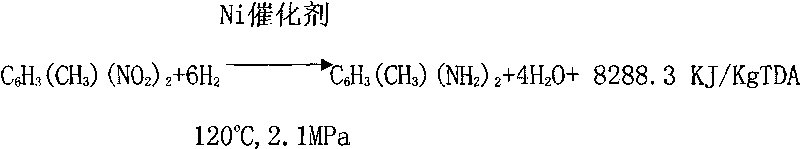

The invention relates to a method for continuously preparing toluenediamine, continuously rectifying toluenediamine so as to separate toluenediamine into expected meta-position toluenediamine (a 2,4-TDA and 2,6-TDA isomer mixture), ortho toluenediamine (a 2,3-TDA and 3,4-TDA isomer mixture) and unwanted tar. The invention is characterized in that a solvent-free hydrogenization process is adopted to carry out gas-liquid-solid three phase hydrogenization reduction reaction under the existence of a nickel catalyst, and then violent stirring is carried out; a mode of combining external circulation cooling and internal coil pipecooling is adopted to take away reaction heat generated in a reactor (1); dinitrotoluene is reduced by hydrogen to generate crude toluenediamine; the nickel catalyst is recycled through the parallel operation of three tilted-plate settling separators, and water is removed through two distilling towers; waste water is delivered to a waste water treating system, and then three distilling towers are utilized to separate the dehydrated mixture into the expected meta-position toluenediamine, the ortho toluenediamine isomer and the unwanted tar, wherein the meta-position toluenediamine is delivered to a TDI synthesis process, the ortho toluenediamine is delivered to a deep processing process and the condensed tar is discharged out of a barrel to be burnt.

Description

technical field [0001] The present invention relates to a kind of continuous preparation of toluenediamine (TDA), and continuous rectification separates it into desired m-toluenediamine (a kind of 2,4-TDA and 2,6-TDA isomer mixture), ortho Toluenediamine (a mixture of 2,3-TDA and 3,4-TDA isomers) and unwanted tars. In this process, dinitrotoluene is catalytically reduced by hydrogenation, separated by settling and reused over the nickel catalyst, water is removed by distillation, and the dehydrated mixture is separated into the desired isomers and non- required high boiling point compounds. technical background [0002] m-toluenediamine is an intermediate for the preparation of toluene diisocyanate. In addition, m-toluenediamine is also used as a dye for hair dyeing. [0003] According to the prior art, m-TDA is prepared by hydrogenation of dinitrotoluene for the preparation of TDI by phosgenation. The hydrogenation reaction can be carried out in the presence of a solven...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C07C211/51C07C209/36C07C209/86

CPCY02P20/584

Inventor 马建军郑世清谭心舜李春欣张伟

Owner 甘肃银光聚银化工有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com