Heat exchange structure used for coal drying treatment

A technology of heat exchange structure and coal drying, which is applied in the direction of heat exchanger type, direct contact heat exchanger, lighting and heating equipment, etc., can solve the problems of easy formation of local high temperature in coal seam, unfavorable dry distillation products, etc., and improve safety and reliability performance, energy saving, and efficient heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

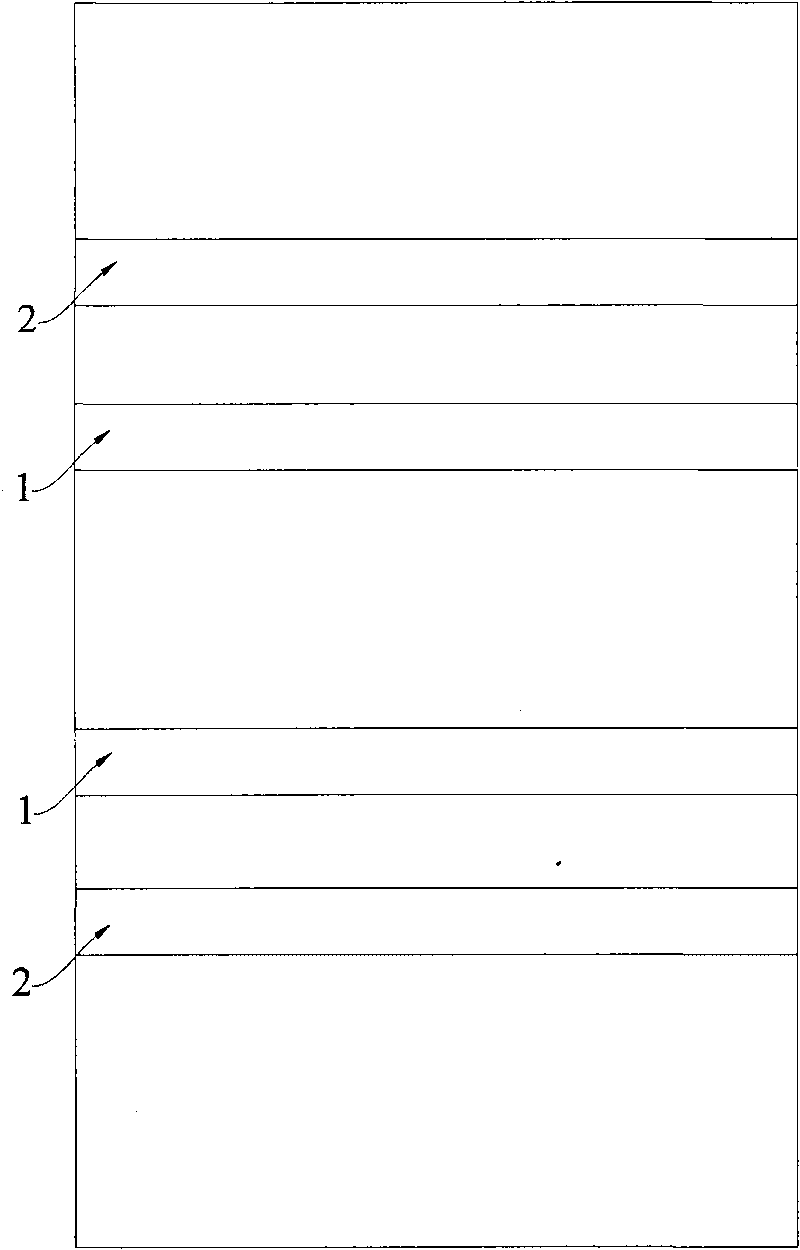

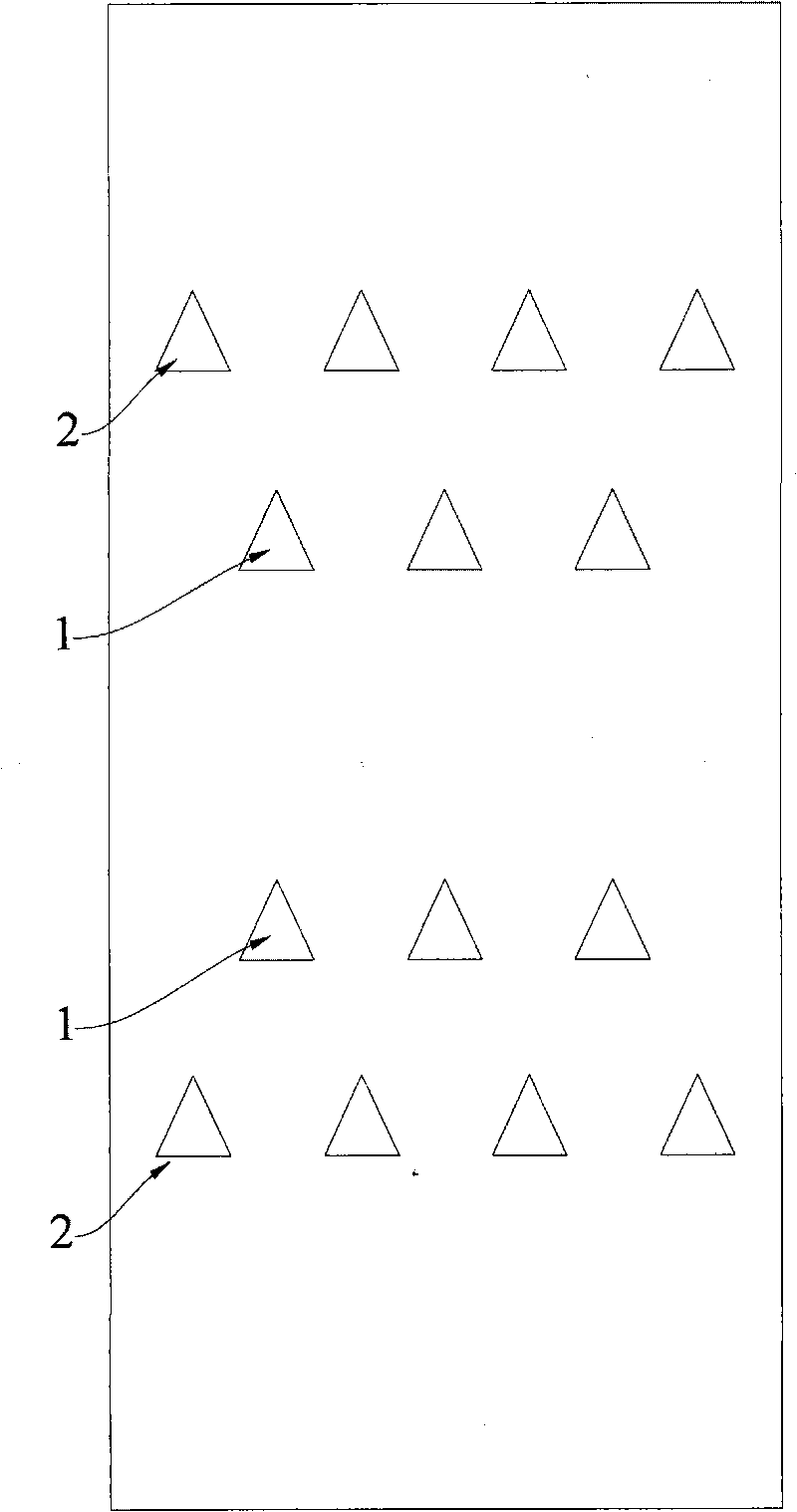

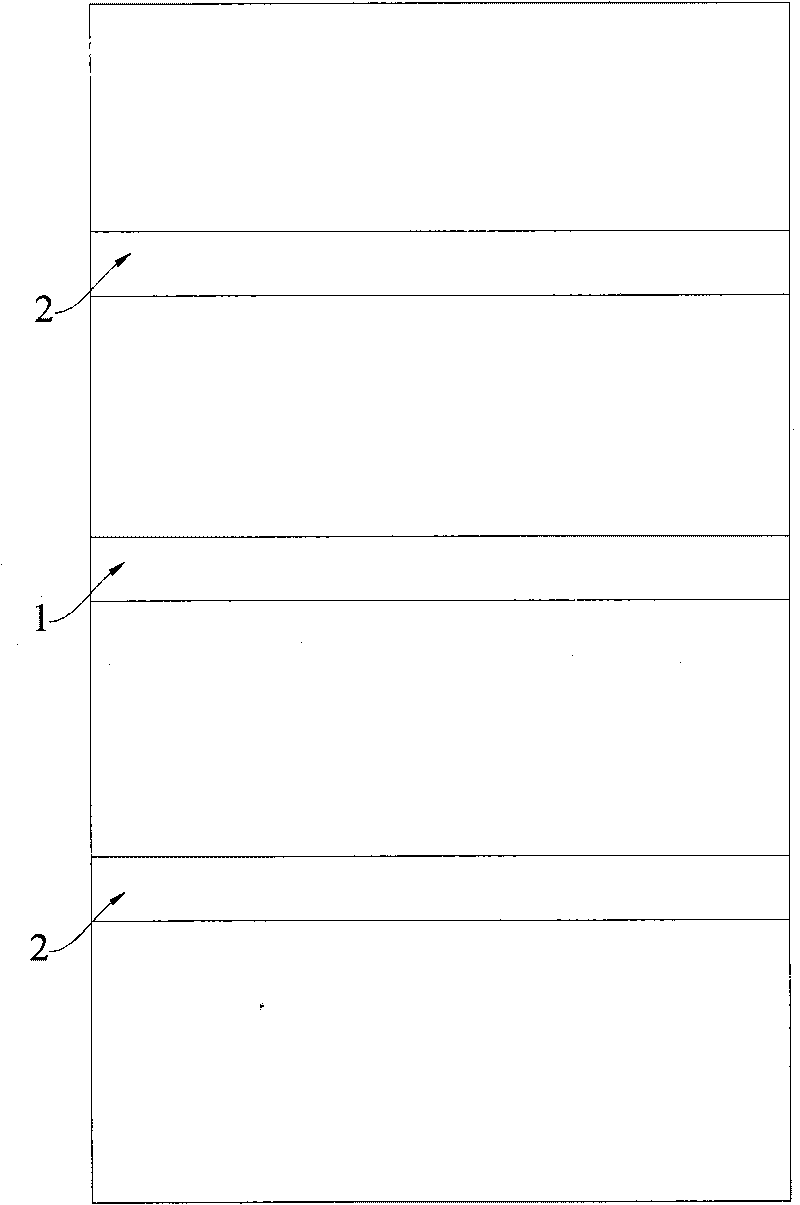

[0027] figure 1 and 2 Shows a specific embodiment of the coal carbonization heat exchange structure of the present invention, a heat exchange structure of the drying section in a coal carbonization furnace, including: a body 3, the upper end of which is suitable for coal block entry, and the lower end is suitable for coal block flow out Two groups of air distribution pipes 1, which are arranged in the middle of the body 3, are used to introduce heat carrier; Each group of air distribution pipes 1 is arranged at the same height in the vertical direction; the air collecting umbrellas 2 at the upper and lower ends of each group are respectively arranged at the same height in the vertical direction. Both the air distribution pipe 1 and the air collecting umbrella 2 are metal pipes with open bottoms. The cross-section of the metal tube in the length direction is triangular.

[0028] The external-combustion internal-heating type coal carbonization furnace applying the heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com