Aluminum-steel combined steel-plate shearing wall

A steel plate shear wall, aluminum-steel technology, applied in the direction of walls, building components, earthquake resistance, etc., can solve the problems of inability to use steel plate shear wall anti-lateral force components, waste of materials, high cost, etc., to reduce economic losses and Casualties, low cost, strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

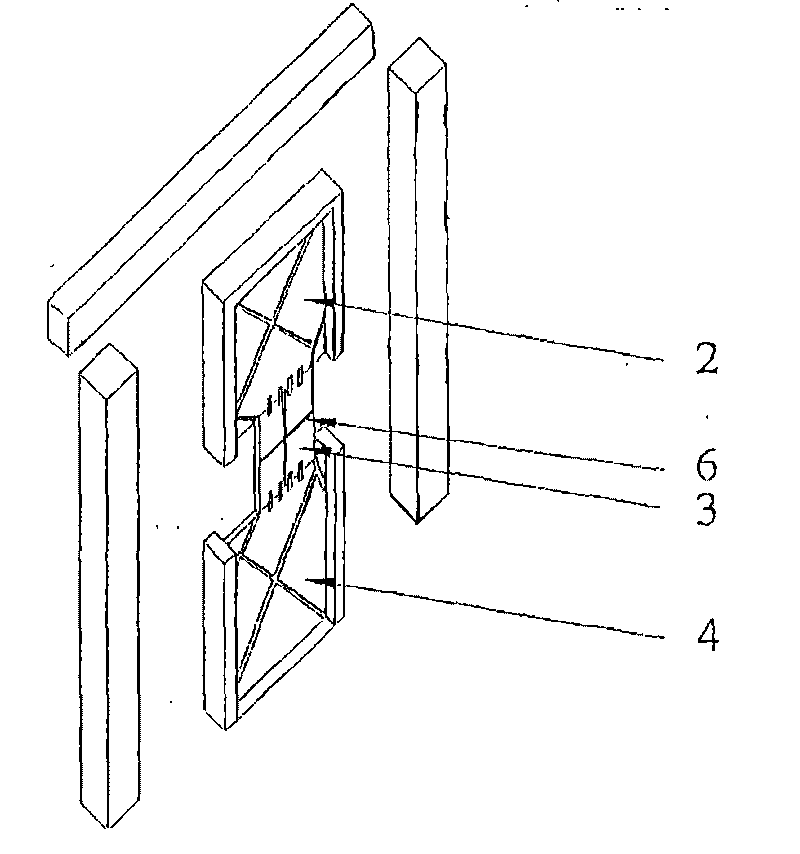

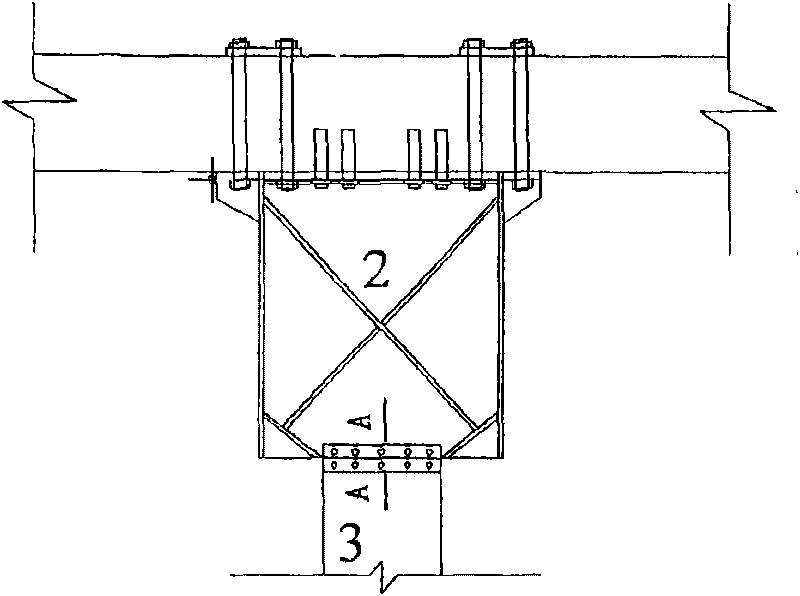

[0012] Example 1: Combination figure 1 , The present invention is an aluminum-steel composite steel plate shear wall, which is composed of an upper connecting plate (2), a core energy dissipation plate (3), a lower connecting plate (4) and edge members, and the upper connecting plate (2) The core energy-consuming board (3) is connected, the core energy-consuming board (3) is connected to the lower connecting plate (4), and the upper connecting plate (2) and the lower connecting plate (4) are connected to the main structure of the building through edge members.

[0013] The present invention also has the following technical features:

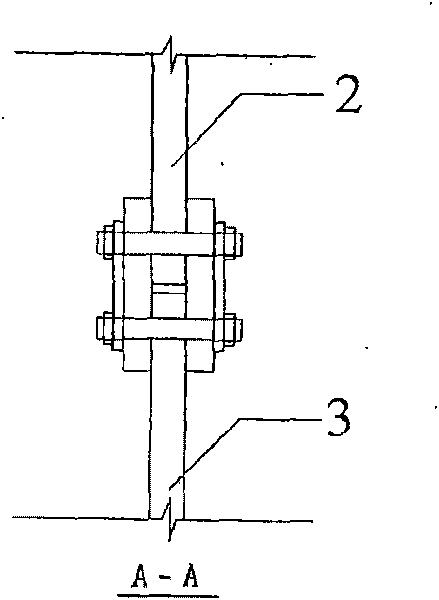

[0014] The core energy dissipation plate (3) is made of aluminum plate with high ductility, high energy dissipation and low yield point, and horizontal and vertical stiffeners (6) are added to reduce the width-thickness ratio of the member to ensure that its yielding precedes buckling ; The core energy-consuming plate (3) is connected with the u...

Embodiment 2

[0016] Example 2: An aluminum-steel composite steel plate shear wall of the present invention, the core energy-consuming plate parts are made of aluminum plates with high ductility, strong energy consumption and low yield point, and horizontal and vertical stiffeners are added to reduce The width-to-thickness ratio of the small component ensures that its yielding precedes the buckling; the practical research results show that its hysteresis curve is full and its energy dissipation capacity is superior; the wall panel does not need to penetrate the entire beam span, it is suitable for opening doors and windows, and the building layout is not restricted; The construction is convenient and the installation is flexible.

[0017] The aluminum-steel composite steel plate shear wall of the invention utilizes the aluminum plate with high ductility, strong energy consumption and low yield point as the core energy-consuming plate, and has the characteristics of excellent energy consumpti...

Embodiment 3

[0018] Example 3: The main specimen of the aluminum-steel composite steel plate shear wall of the present invention is set between two beams of the building structure, the elevation of the building structure is 4.2m, and the net height under the beam is 3.6m; the size of the main specimen is 1.2m×3.6m , in which the core energy dissipation plate has a size of 600mm×600mm and is composed of webs, flanges and stiffeners. The size of the web is 564mm×564mm×6mm, and a stiffener is set in each direction to divide the web into 2×2 squares. The size of the stiffener is 564mm×107mm×12mm. The flange dimensions are 600mm x 220mm x 18mm. Researches are carried out from the aspects of hysteresis curve, energy dissipation performance, strain analysis, ductility performance and stiffness, etc. The experiments prove that the aluminum and steel composite steel plate wall proposed by the present invention improves the traditional steel plate wall by using aluminum plate as the main energy dis...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap