Medium pressure chromatogram purification column

A chromatographic purification and purification column technology, which is applied in the design and filling field of medium-pressure chromatographic purification columns, and can solve the problems of mobile phase leakage sealing device, high manufacturing cost and use cost, shedding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

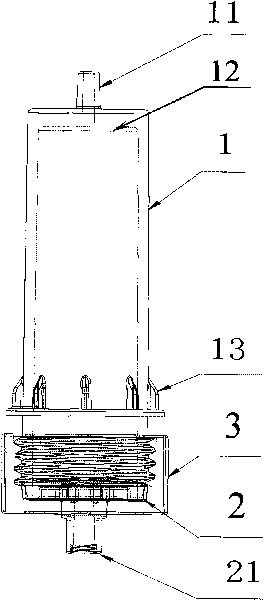

[0023] figure 1 A schematic diagram showing the structure of a medium-pressure chromatographic purification column. The medium-pressure chromatographic purification column with a cylindrical structure includes a column body 1 molded with an outlet pipe 11 and a reinforcing rib 13 , a sealed inner plug molded with an inlet pipe 21 and a perforated gland 3 . During operation, the mobile phase flows from the inlet pipe 21 into the medium-pressure chromatographic purification column, and flows through the packing material to the outlet pipe 11 .

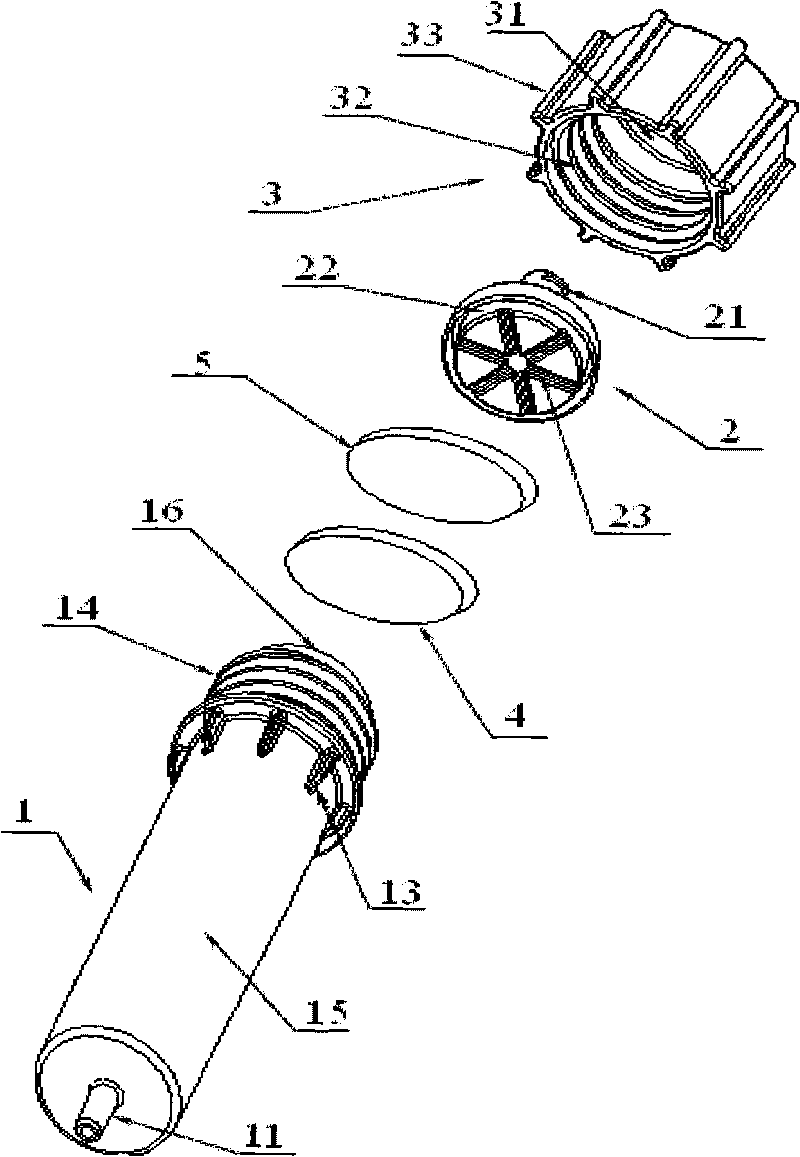

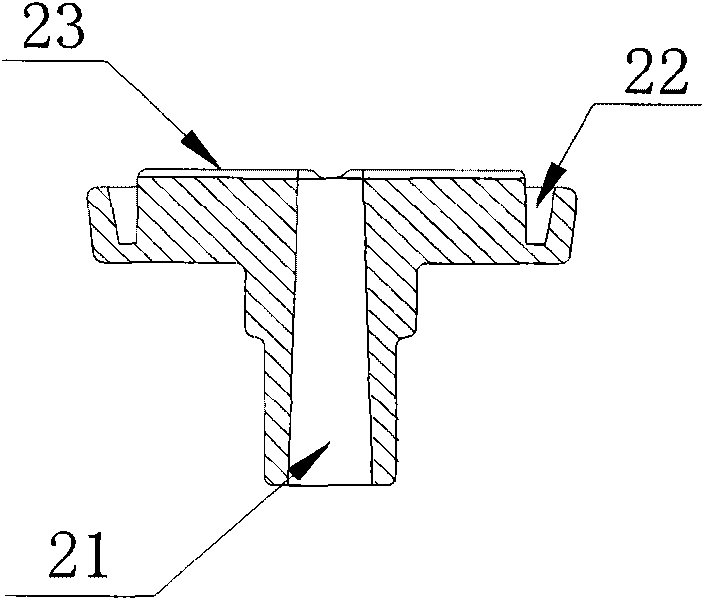

[0024] figure 2 The medium-pressure chromatographic purification column is shown to include 5 parts in turn: a column body 1 molded with an outlet pipe 11, a molded diversion groove 12, an external thread 14 and a reinforcing rib 13; an inlet pipe 21, a molded A sealing inner plug 2 with a distribution groove 23 and a groove 22; a perforated gland 3 with a through hole 31 and an internal thread 32; an inlet filter 4; an outlet filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com