Silicon chip cleaning device of chemical and mechanical polishing equipment

A technology of silicon wafer cleaning and chemical machinery, applied in the direction of chemical instruments and methods, cleaning methods and appliances, etc., can solve the problems of material loss, affecting device quality and yield rate, etc., achieve accurate positioning, reliable cleaning and reset, and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

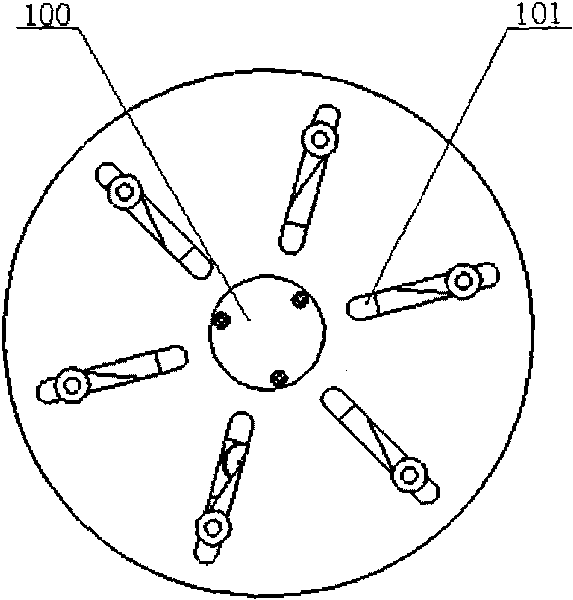

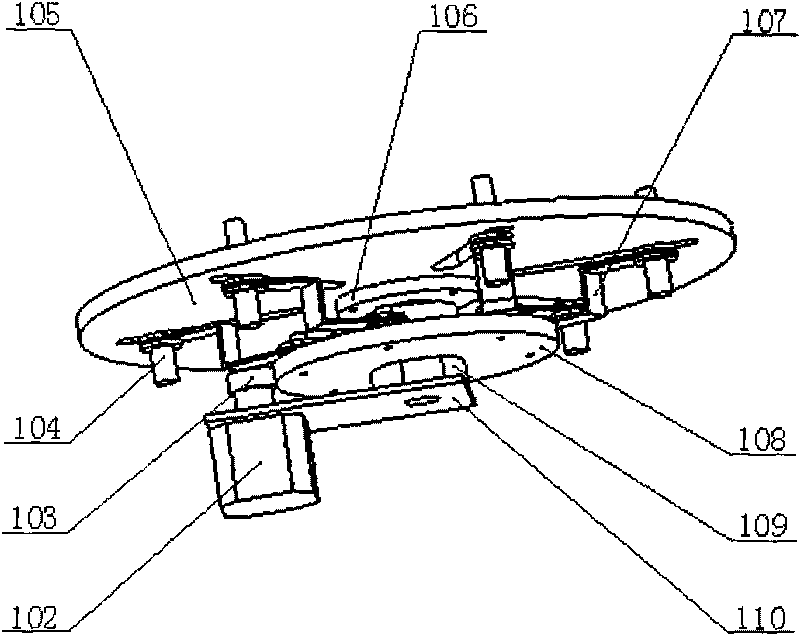

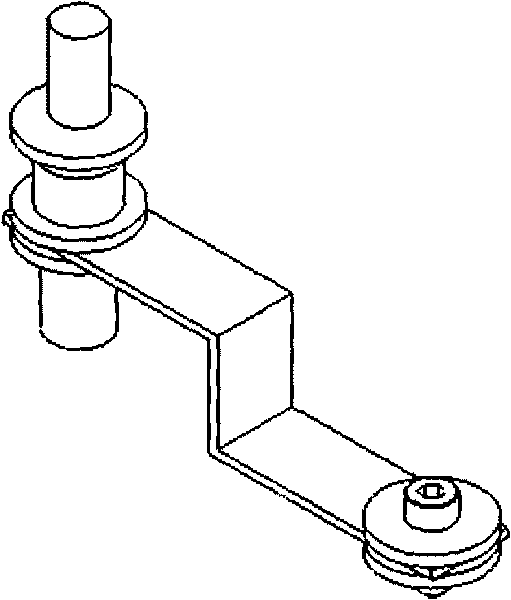

[0018] see Figure 1 ~ Figure 3 , the silicon wafer cleaning device of chemical mechanical polishing equipment has a silicon wafer positioning support 100, and the silicon wafer positioning support 100 is fixed on the center plate 105. rotating device. The structure of the silicon wafer positioning holding and reset device is as follows: the center plate 105 is provided with 3 or more strip-shaped holes 101 arranged radially toward the center, and the strip-shaped holes 101 are provided with finger pads with wedge angles on the inner edge The sliding block 204, the finger pad sliding block 204 with a wedge angle on the inner edge and the drag hooks 206 are rotationally connected, and each drag hook 206 is twisted with the turntable, and the turntable is connected with the power transmission mechanism.

[0019] The power transmission mechanism is: the turntable itself is a large gear plate 108, the large gear plate 108 meshes with the small gear plate 103, the small gear plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com