Method for preparing Ti2AlN/TiAl compound material by regulating and controlling components accurately

A composite material and precise technology, applied in the field of composite material preparation, can solve problems such as easy introduction of impurities and difficulty in achieving large-scale control of TiAlN volume fraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

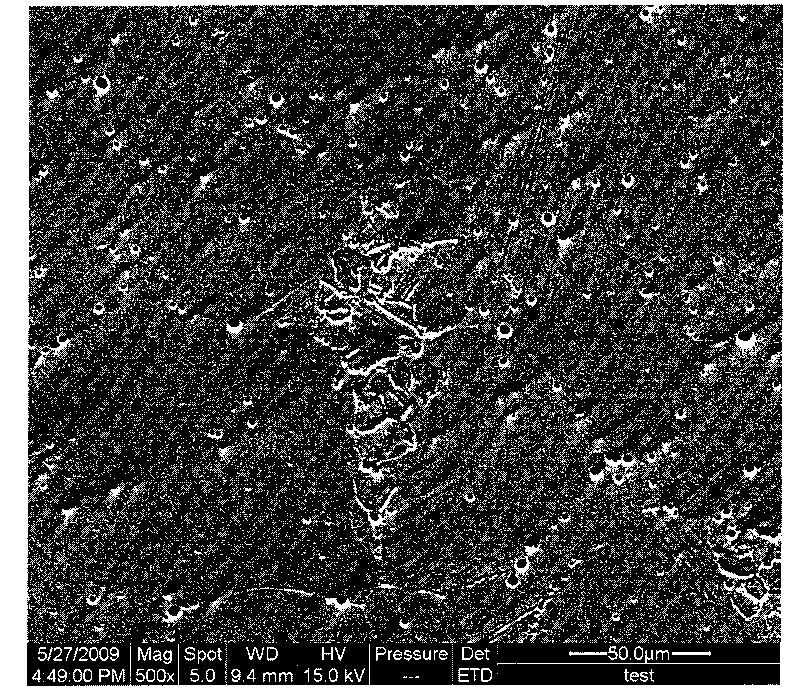

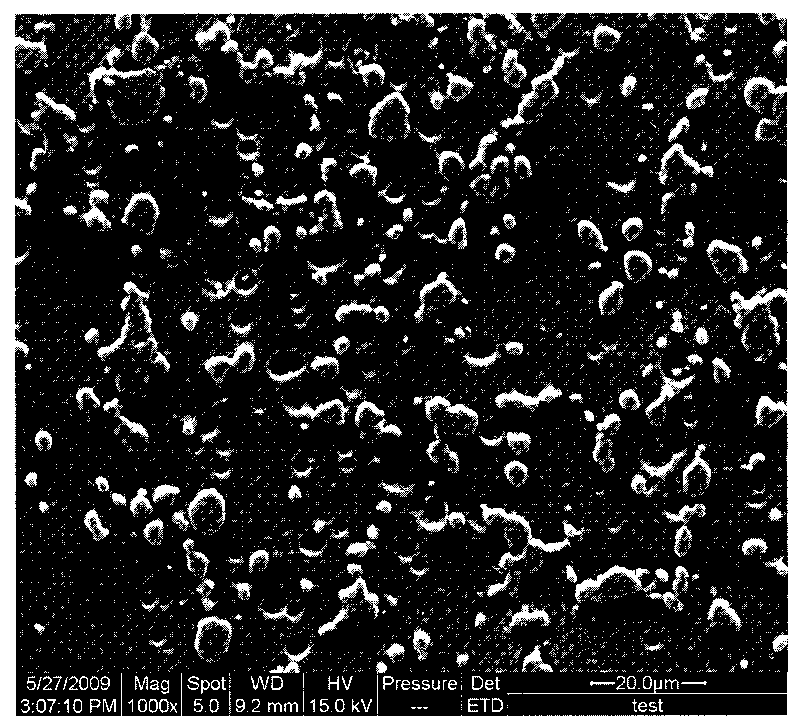

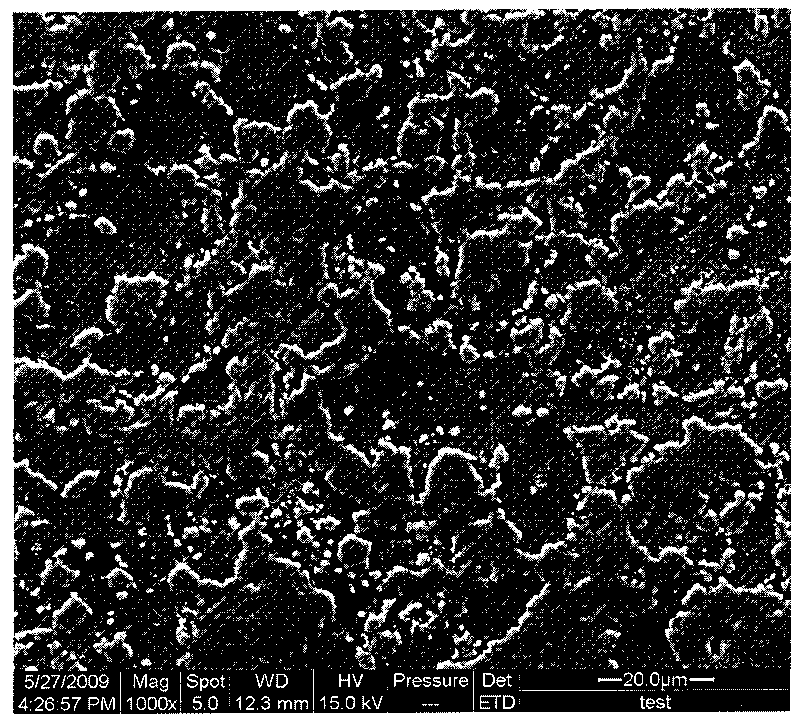

Image

Examples

specific Embodiment approach 1

[0011] Specific embodiment one: a kind of Ti in this embodiment 2 The preparation method of precise control of AlN / TiAl composite material components is as follows: 1. Put Ti powder, Al powder, TiN powder and alloy element powder into the liquid dispersant, and then add Ti powder, Al powder, TiN powder and alloy element powder The ratio of the total weight to the weight of the balls is 1:5, and the rotation speed is 300 revolutions per minute, and the ball milling is performed for 3 hours to 24 hours, and then dried at a temperature of 50°C to 100°C to obtain a mixed powder; 2. Put the mixed powder into a graphite mold, raise the temperature from room temperature to 700°C at a rate of 10°C / min, and then keep the temperature and pressure at 700°C and a pressure of 20MPa to 60MPa for 1 to 4 hours; 3. After step 2, the graphite mold with mixed powder is raised from 700°C to 900°C at a rate of 10°C / min, and then kept at 900°C and pressure of 20MPa to 60MPa for 1 to 4 hours. ; 4. ...

specific Embodiment approach 2

[0013] Embodiment 2: This embodiment differs from Embodiment 1 in that the liquid dispersant described in step 1 is alcohol, acetone or distilled water, and the others are the same as Embodiment 1.

specific Embodiment approach 3

[0014] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the alloying element mentioned in Step 1 is one of Nb, Cr, Mn, Si and B or a combination of several of them. Others are the same as in the first or second embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap