Micro-mechanical tuning fork gyroscope of horizontal shaft

A tuning fork gyroscope and micro-mechanical technology, applied in the direction of gyro effect for speed measurement, gyroscope/steering induction equipment, generator/motor, etc. It is difficult to solve the problems of performance degradation such as mechanical coupling of gyro driving mode and detection mode, variable area detection capacitance linearity, etc., and achieve the effect of large range, solving mechanical coupling problems and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

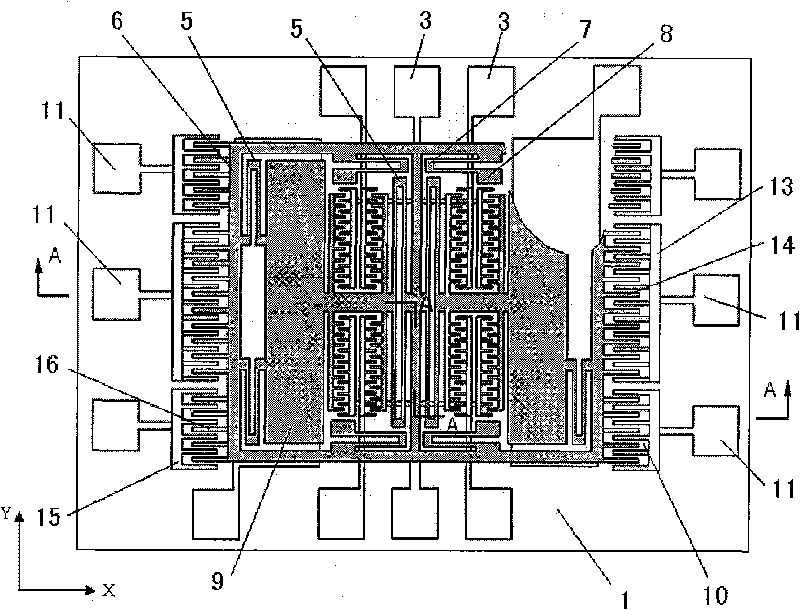

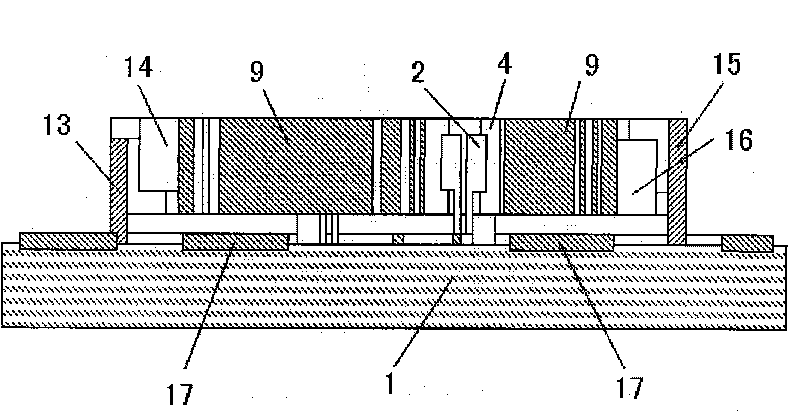

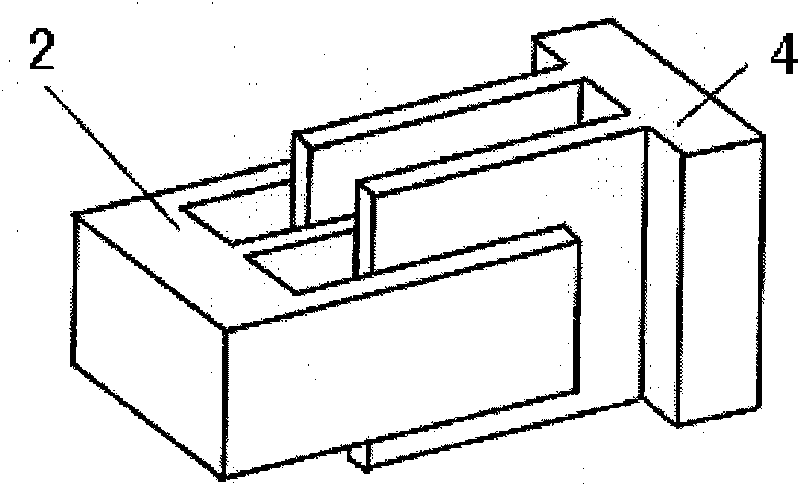

[0020] like figure 1 , figure 2 As shown, the present invention includes a substrate 1, a driving unit composed of a fixed driving comb 2, a driving electrode 3, a movable driving comb 4 and a driving folded beam 5, a frame 6, a detection folded beam 7, an anchor point 8 and a sensitive mass A sensitive unit composed of block 9 and a detection unit composed of two types of variable-area vertical comb-tooth detection capacitors 10 , corresponding detection electrodes 11 and differential detection variable-gap detection capacitors 12 . Among them, the variable-area vertical comb detection capacitor 10 includes a type I fixed vertical detection comb 13, a type I movable vertical detection comb 14, a type II fixed vertical detection comb 15 and a type II movable vertical detection comb 16; The capacitor 12 includes a detection plate 17 .

[0021] On t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com