Periphery supporting mechanism of reflecting mirror in space remote sensing camera

A support mechanism and remote sensing camera technology, applied in the field of space optics, can solve problems such as poor dynamic performance, inability to meet environmental conditions, aerospace needs, and inability to effectively reduce the impact, etc., to achieve the effect of good integrity and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

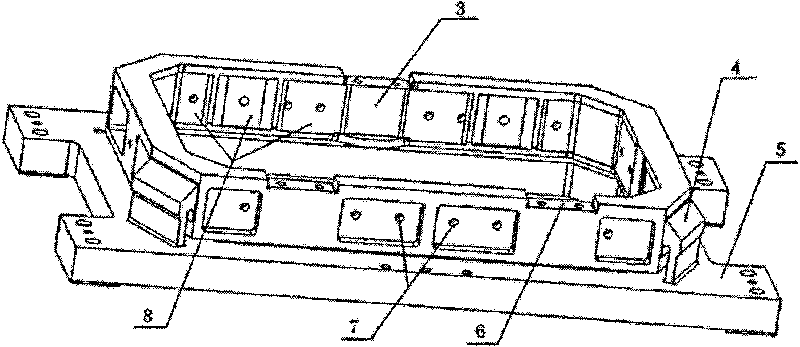

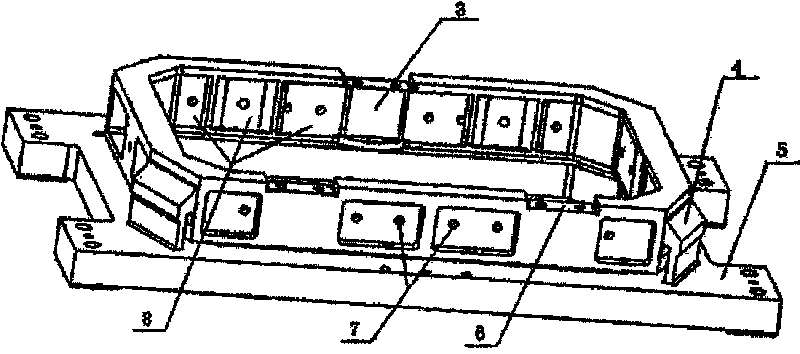

[0010] The invention according to figure 2 In the implementation of the structure shown, the materials used for the mirror chamber 3, the flexible support sheet 4 and the bottom support plate 5 included in the peripheral support mechanism are all low-expansion alloy Invar, and the coefficient of linear expansion is 0.36×10 -6 K -1 ;The mechanical structure of this product is divided into three layers, but in the process of manufacturing, it can be made into one piece according to the processing process, so that the structure implemented in this way reduces the connection links, increases the reliability of the structure, and improves the overall performance of the structure. The mirror chamber 3 of the peripheral support mechanism and the reflector have three support points in the axial direction, which are used for the axial positioning function of the reflector, and the three support points are required to be coplanar to ensure the position accuracy of the reflector. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com